M16 / M16A1: my little analysis…

On February 28th, 1967, the U.S. Army officially adopted the M16A1. Three years earlier, the US Air Force had adopted the M16. Derived from Armalite Rifle No. 15 (AR-15) these two very similar weapons were resolutely modern – and even revolutionary – in their time while being technically mediocre. We will analyze here these different aspects, as well as the reasons for the adoption of this weapon so controversial by one of the largest armies in the world.

The Revolution

It does not really come from the significant use of aluminum alloy in the construction of the weapon: lower and upper receiver mainly, the two most massive parts. Other weapons had already used these materials, whether experimental (MP-38(L), Germany), anecdotal (CSRG 1915, France, the “Chauchat” has an aluminum sleeve around the barrel … like a PGM Ultima Ratio!) or for mass production (the massive feeding corridor of the Soviet Maxim PM 1910 machine guns was built in bronze and then aluminum for obvious economic reasons). Similarly, the AR-10, direct ancestor of the AR-15 and designed just like the latter by ArmaLite had already implanted in the gunsmith landscape this type of weapon in the mid-1950s. And let’s be rational: the use of aluminum has above all an advantage for the industrialist: making an AR-15 receiver in forged / machined aluminum alloy is much cheaper than a forged / machined steel receiver. This allows to reduce costs significantly, especially on limited production scales (thousands of weapons). On a very large scale (several tens of thousands of weapons), the comparison with the use of stamped sheet metal can however raise questions. Personally, the use of sheet metal seems to us more advantageous overall, because it is more economical in raw materials, and probably faster in terms of production, especially before the invention of CNC machines (at the end of the 1970s). It is often put forward that for the user, this choice induces a weight gain of major importance. But we must also put things into perspective: if the AR-15 is often described as extremely light, a quick comparison to our scale balances the stats (in descending order):

- AKM, with 30-round ribbed steel magazine (0.9 mm sheet) empty, 3.656 kg (+ 209 g than the M16A1)

- AKM, with 30-round AG-4 magazine (steel / synthetic) empty: 3.584 kg (+ 137 g than the M16A1)

- AKM, with empty aluminum 30-round magazine, 3.523 kg (+ 76 g than the M16A1)

- M16A1, with 30-shot empty aluminum magazine: 3.447 kg

- AK-74, with 30-round AG-4 magazine (steel / synthetic) empty: 3.406 kg (- 41 g than the M16A1)

- Vz.58, with empty aluminum 30-shot magazine: 3.149 kg (- 298 g than the M16A1)

Remember that the Vz.58 is made from a forged / machined steel frame and uses an unlinked piston which can be described as more than massive! It breaks the myth… Admittedly, the M16A1 has a barrel about 9 cm longer than other weapons: but is this really a quality given the ballistic yield of the 5.56×45 mm and faced with the problem of bulk? Like the use of aluminum, the use of synthetic materials for the manufacture of furniture was modern, but not revolutionary.

The revolution also does not come from the use of a rotary lock with 7 lugs locked in a nut screwed directly on the barrel: the entire lock is directly inherited from the systems developed by Melvin Johnson (with his rifle and LMG model 1941 – Pic.04). It should also be remembered that the latter was also a particularly active consultant at Armalite at the time of the development of the AR-10. Talk about the “brilliant inventiveness” of Eugene Stoner … Others would draw a parallel here with the presence of Hugo Schmeisser in the USSR (and probably in Ishvesk) at the time of the finalization of the AK-47… And yet, there are more similarities between a Stg-44 and an AR-15… than with an AK-47! But that’s another story… Personally, we do not believe at all in a possible contribution of Hugo Schmeisser in the design of the AK-47: there is simply nothing really German in the Soviet weapon!

The revolution does not come from the quite mediocre use (I spoil a little the rest of the article …) of the direct gas impingement. The direct gas impingement system was previously used – more intelligently – on other weapons such as the Swedish AGM-42 and the FSA MAS family in France. But we will come back to the mechanical points in more detail later.

The real revolution comes from the caliber: the 5.56×45 mm, soberly named “5.56” by the US administration at its adoption and .223 Remington by its civilian designers (Pic.05). A detailed article (especially on the technical and normative levels) on this subject being available on this same site (linked here), we will limit ourselves here to the analysis of the tactical implications of this choice. The adoption of the “5.56” marks a turning point in small-arms, as it is the first second-generation intermediate caliber adopted by a major army… and even to our knowledge by any army at all. As a reminder, the first-generation intermediate calibers are generally the result of a reduction in power (by reducing the weight of the bullet and the propellant load, and consequently the size of the case) of the war calibers already in service until the beginning of the WWII: we can mention in particular for the most well-known:

- The German 7.92×33 mm Kurz. (The caliber of the “Strumgewehr”)

- The Soviet 7.62×39 mm. (The caliber of RPD-44, SKS-45, AK-47 and AKM)

Despite several studies in countries of the Western sphere after WWII, no intermediate caliber of the first generation will ever be adopted in the West. In our opinion, the .30 Carbine, by its ballistic performance, clearly does not belong to this category. Instead of a first-generation intermediate caliber, we will be gifted with the 7.62×51 mm, whose ballistics are extremely close to the .30-06 Springfield but ultimately also to … the 7.62×54 mm R! The Belgians and the British may still remember it…

The second generation of intermediate calibers keeps pushing the path of reduction by targeting the diameter of the bullet and therefore the barrel. We thus obtain a lighter bullet, which with a slightly lower propellant load, comes out at high speeds: conventionally between 850 and 1000m/s… if the length of the barrel allows it. The other famous example is the excellent Soviet’s 5.45×39 mm, but we could also mention the Chinese’s 5.8×42 mm (which seems to be heavily inspired by the 5.45×39 mm). The advantages of these calibers are multiple:

- Reduced ammunition weight compared to first-generation ammunition. This parameter really and favorably impacts military logistics at all levels: from the soldier to the transport aircraft, one carries more ammunition (and therefore shots) at an equivalent weight. And that’s not to mention industrial considerations: ammunition that consumes less raw materials… therefore more economical.

- Due to their high initial velocity, a flatter trajectory over the “usual” distances (i.e. understand here, the distances with which without optical means, the fighter is able to detect and discriminate a target by favorable geographical and weather conditions, that is to say from 300 to 400 m approximately): this will increase the hit probabilities, even on a moving target. Indeed, the reduction of flight time allows, by reducing all the factors that affect the shooting parameters, the reduction of the gap between the point targeted and the point to be reached. The ideal would be a “laser beam” (faster than those from Star Wars however… “Punch it Chewie! ») … But you still have to aim well! It is necessary to recall here that this type of weapon is primarily intended for “non-professional” soldiers, conscripts or “fixed-term contracts” (without any contempt of any kind for these soldiers: what else can I say about a 5-year contract?), whose training is not in relation to what should be expected of a professional and seasoned soldier. The use of the weapon will therefore be in unfavorable conditions… the gain in mastery of shooting by the artifice of the caliber used will be even greater!

- Low recoil: it promotes a faster target re-acquisition between shots in semi-automatic mode (primary vocation of an assault rifleAn assault rifle is a weapon defined by the use of an "inter... More) and a better control of burst fire. It even reduces the apprehension of the use of the weapon. The subject of burst shooting is widely covered in three articles available on the site: “Some thoughts about burst shooting“, and “Assault Rifles: how they behave, Part 1 and Part 2“. Happy reading!

In the end, some see it as an increase in “firepower”. If the matter can be agreed, it remains to agree on a precise notion of “firepower”. Here too, reading the article “Some thoughts about burst shooting” offers food for thought on this subject… Let us avoid repetition but let us not take too many shortcuts either.

Be careful, revolutionary does not mean miraculous!

Because if the picture drawn here of second-generation intermediate calibers seems perfect, there is a price to pay: and in this case, it is obviously the terminal efficiency. It is not judged solely on the effects in a block of gelatin or ballistic soap (or any other very sophisticated and very expensive device) fired 5 meters away from the weapon … or on watermelon shots at a garden party. No, it is judged with complete batteries of tests, including in particular the perforation of materials, the wound ballistics over ranges of variable distances and representative of those envisaged for use. And it is here that the “5.56” (and especially the M193 of the time) is rather mediocre when you go over 150 m. And we are only talking here about weapons equipped with a barrel about 50 cm long like the M16 and M16A1 … The results are worse on shorter barrels, bien entendu. For a weapon with sights allowing engagement up to 375 m, this can raise questions. But we must not lose sight of the fact that the choice of a caliber is always a compromise: what is it for? If the intermediate calibers (first and second generation) clearly have a vocation of “versatility”, it should not be forgotten that the criteria of this versatility must clearly dictate limits, in accordance with the laws of physics. One thing that some users tend to forget. In summary, we must not confuse here “versatile” and “universal”. But that’s another topic…

In any case, the adoption of “5.56” will be a real revolution for the entire Western bloc, for better and for worse.

Mediocrity

The term is chosen, weighed, carefully thought through. Yes, the majority of the mechanical choices of the AR-15 are objectively MEDIOCRE. I feel like I’m going to make a lot of buddies here… well, among the readers who are still here (thank you!).

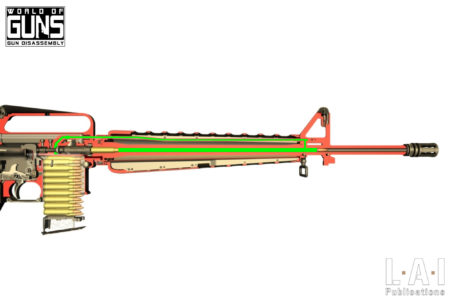

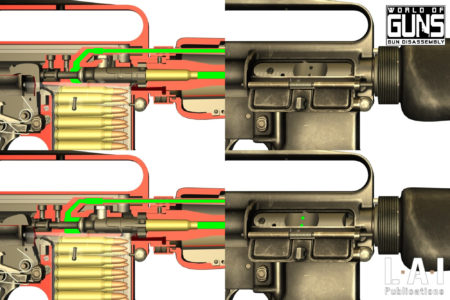

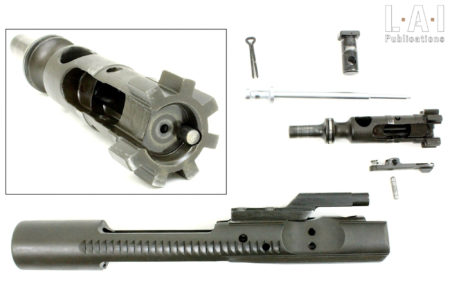

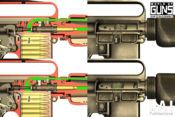

We will not return here to the principle of the gas-operated system, the thing being described in luxury details in Chapter 6 of the “Small Guide to Firearms” available here. Here, E. Stoner chose the so-called “direct impingement” system, which “saves” the use of a piston. In any case, in a well-designed gas-operated system, as soon as the rearmament impulse is given, the designer will be keen to evacuate the gases out of the weapon as soon as possible. Because the gases, burning and dirty, will pollute the weapon and ultimately harm its proper functioning. Just like the AR-10, the AR-15 does exactly the opposite. It takes the gases and contaminates almost all the moving parts with it (Pics.06 to 08). Let’s see how.

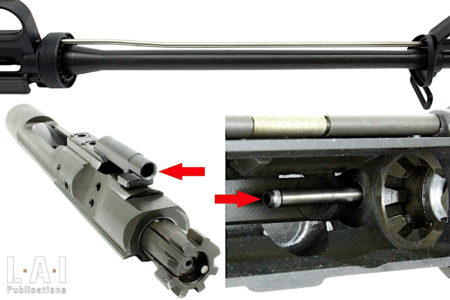

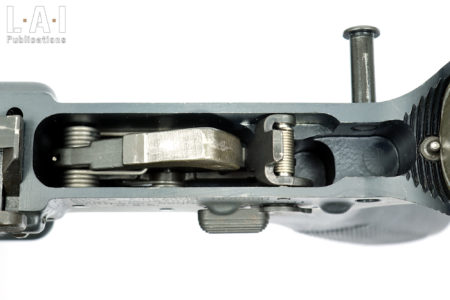

The gases are taken from the gas block and are conducted via the gas tube to the “key” of the bolt carrier. The gases will continue their journey inside the carrier by pushing it backwards (this is the impulse sought for rearmament) and pushing forward the rear of the bolt (and one wonders why…). Note here that three rings are positioned on the rear part of the latter to contain the gases, especially in the face of the expansion of the parts, and especially to scrape the carbon deposited in the bolt carrier shot after shot (Pic.09). For the most curious, the layout is absent from early versions of the AR-10. Thus, after the impulse of the carrier “by a short but energetic” set in motion of the latter towards the rear, the gases are finally evacuated by the two vents on the right side of the bolt carrier visible in the ejection port (Pic.10). We already have here the path of gases that take about 2/3 of the barrel, will be brought behind the bolt, polluting and heating the bolt carrier group from the inside: unprecedented … and for no real reason! Because yes, we of course understand the original idea: the path of the gases is intended to evacuate them out of the weapon through the ejection port because the receiver is globally closed: thus, it is not possible to be satisfied with an evacuation at the exit of the gas tube, as on the AGM-42, MAS-49 (as well as their derivatives, including the Rasheed carbine… Article here for a detailed example!). But this is not a real reason, because with a minimum of knowledge about small arms mechanics, at this stage of the design of a weapon … we already know that we are taking the problem backwards.

In theory, part of the deposit scraped by the gas rings is evacuated by the excess gas from the next shot. However, through the lack of real sealing of the assembled parts (at about 1050 bars of gas pressure when the bullet passes the gas port, any attempt to seal an assembly of moving parts would be illusory), pulverized grime is found everywhere: on the firing pin and even behind the extractor (Pic.11). And in this respect, just like the firing pin, the disassembly of the extractor is of the user level on a field disassembly. This fouling is completed by the breaking of the connection between the gas-tube and the “key” of the carrier during the recoil of the latter. This contaminates the entire receiver/frame, including ammunition, with residual pressure. These effects are highly dependent on the quality of the powder used, and the weapon is heavily dependent on the “quality” of the ammunition. This did not fail to aggravate the case of the M16 and M16A1 to their commissioning in Vietnam: the American administration will encounter many difficulties related to the choice of powders by the various ammunition suppliers. But we could devote an entire article to the problem of gunpowder in automatic weapons. No, once again not all ammunition is equal, even if some brainless people claim the opposite…

And this is only a first perverse effect of this “Stoner” system. Because in case of overpressure in the barrel (conventionally due to the presence of liquids or a bullet stuck at the time of firing), this system transfers the said overpressure (if it reaches the gas port) to the entire gas system. Therefore, the bolt carrier group is potentially subject to this overpressure. As a bonus, it does not accelerate the opening speed of the mechanisms as on a conventional gas-operated or even a blowback weapon (including lever and roller mechanical advantaged systems), but on the contrary it pushes on the back of the bolt as well as on the carrier preventing the opening. What then happens in this closed circuit under pressure before the bullet and what encumbers its passage come out of the barrel? KABOOM! The most fragile piece breaks first. Almost systematically, it is the bolt carrier that bursts, opening on its lower part or / and on one side. This results in ejection (and destruction) of the magazine and bursting/swelling of the upper receiver. The bolt can also be severed on its part receiving the cam pin… In all cases, the weapon is destroyed by the incident. Note that it is logical that it is the bolt carrier that breaks and not the barrel: the latter is designed to withstand significant pressures, while the bolt carrier is a real Gruyère cheese (which actually does not have holes) pierced and machined on all sides. The gas-tube is designed to cope with a certain pressure and in fact contains a small volume of gas, whose action is distributed over a large area. Moreover, the part had already been redesigned at an early stage of the weapon development because of this problem…

Faced with this problem, Armalite and Colt will obtain from the American authorities during the evaluations (which were not carried out for adoption) of the AR-10 and AR-15 that the protocol is biased (sorry “modified”) for testing weapons by draining the barrels after they have been exposed to water (and even rain…). Immediately after its adoption, the US Army disseminated in these instructional media the instruction that it was imperative to avoid the presence of water in the barrel under penalty of explosion of the weapon (in particular with the video entitled “Rifle M16A1 Field Expedients” 1968 US Army” and by the comic strip dealing with the weapon’s maintenance, available at the end of the article). Because obviously, the American military authorities are perfectly aware of the problem(s)… But it is well known that at that time, the United States was not engaged in a country with a humid climate (ironically, of course: it was in the beginning of the Vietnam War, in a country with tropical and subtropical climates marked by monsoons).

In other weapons, overpressure almost systematically leads to a faster opening of the breech mechanisms (and the “over-cycle” that is linked to it). The pressure thus drops quickly because the gases flow back through the chamber. The damage is often confined to the barrel (bulge, and in some extremely rare cases, a “tear”), and a deformation of the parts during their violent interaction. No “explosion” of the weapon (possibly, breaking the case head separation) in the literal sense of the word, this is a privilege of the AR-15 and its use of the direct gas impingement.

If, as mentioned, we can very well use the gas-tube system rationally (where the gases are therefore immediately exhaust into the open air through the large ejection port as soon as the impulse is given to the only part that needs it: the bolt carrier), this system does not find particular favor in our technician’s eyes. It has no intrinsic advantage: gases should always be evacuated as quickly as possible… and not conveyed through the weapon. And contrary to preconceived ideas on the subject, this does not allow either simplification of the weapon (in number of parts or machining), nor lightening of the bolt carrier group! In addition, the mass of the bolt carrier group is necessary in the rearmament process… So, we might as well make it useful! In the case of the AR-15, one need to add the buffer’s mass… which is part of the mobile parts (Pic.12)! Again, let’s bust the myth by comparing the mass of some mobile parts measured by us (descending order):

- AK-47: 516 g (+ 45 g than the M16A1)

- FNC: 506 g (+ 35 g than the M16A1)

- AKM: 499 g (+ 28 g than the M16A1)

- AK-74: 484 g (+ 13 g than the M16A1)

- M16A1: 471 g

- SAR-80: 464 g (piston included! – 7 g than the M16A1)

Is that all? No, because obviously, the bolt carrier group heats up by this system. The consequence? The cook-off threshold is ridiculously low. Here too, the army was well aware of this: in November 1960, a series of tests concluded that the threshold was crossed after 140 rounds fired in bursts in 53 seconds. The same report reassured itself by specifying that the threshold is not crossed after 120 shots fired in 39 seconds. There are several ways to consider these figures, but first, remember that at 750 rpm (average rate announced by Wikipedia… Our measurements are above: 837 rpm on one session and 778 rpm on a second session) a 20-round magazine is fired in 1.60 seconds. Thus, 140 rounds represent 11.2 seconds of firing: of course, the remaining 41.8 seconds are those used to change the magazines in an industrial test context, or 6.97 seconds per magazine change. Nothing shocking. We may even say… one takes its time! But once again, this is not shocking in this type of protocol: make no mistake, the few seconds saved on a hastily made magazine change will not change the results at all (nor give victory on a battlefield…). Might as well do things well and calmly. For the 120 shots: without spreading out the detail here, it makes us reload in 5.88 seconds. Let’s clarify that these are necessarily two distinct series of tests: the cook-off threshold is normally verified by the absence of a shot start, chambered weapon, over a fairly long period (up to 2 minutes) after the last shot fired. Once this mathematical moment is done, what can we say? 140 shots stand for 7 magazines of 20-round… but less than 5 magazines of 30-round! And 120 shots? Well, that’s only 4 30-round magazines. The threshold is clearly too low for an automatic weapon: it should in no way be close to or lower than the infantryman’s magazine endowment! But here, it looks like it seems to be “acceptable”…. The administration moves in mysterious ways.

(Why were Danny de Vito & Bud Spencer working for IMI by that time? Let’s find out…)

What would have pushed E. Stoner to select this operating-system would have been the will to reduce all the masses in motion (and we have seen that the gain is marginal, enough to doubt this assertion: Mr. Stoner was certainly not stupid). Whatever the reason for this initial choice, the patents for this gas-tube system were sold by Colt for “only” (these are the words of the authors of “The Black Rifle”) $75,000 and 4.5% royalties in 1959. The fad of the “direct impingement” quickly passes to E. Stoner: he will abandon it definitively with the design of the AR-16, his next weapon and the last he will do for Armalite… Still in 1959. If some will say “it is the monopoly of the patent that means that no one else has used it or that Stoner has no longer used a gas impingement”, the thing can only be understood for the design precisely covered by the 1956 patent filed by Stoner: the one that goes all over the bolt carrier group. The other gas direct impingement systems are not of his making: he could therefore have designed a new system using a gas-tube, but not going – or not in the same way – through the bolt carrier group. Finally, the fall of the patent has in no way led to a major diffusion of this system in military weapons: the use of the direct impingement is marginal in the small caliber weapon of war industry. Except for Canada (whose choice is political rather than technical), the few countries that had made a mistake in buying licenses from Colt will veer very much towards the use of pistons, linked or not. Manufactures for the civilian market cannot be taken into consideration, the needs and specifications of this type of market being incommensurate with those of an army… As for the military units that continue to buy civilian equipment off the shelf by mistaking pulling wool over their own eyes, they should not be surprised when their magnificent Seekins in 6.5 mm explodes when the first obstruction test is carried out… As you will have understood, this is a case actually witnessed no later than 2022… But I don’t wear sunglasses, I don’t do shooting “courses”, and I don’t sell dreams… So don’t listen to me!

Finally, the most “achieved” of E. Stoner’s weapons, the Stoner 62, 63 and 63A (made at CADILLAC Gage Inc.) will have a driving principle very close to … the Kalashnikov! Certainly M.T. Kalashnikov did not invent the use of linked piston gas-operated system, but he never claimed it. It should also be noted that Colt, proud owner of the AR-15 patent sold by ArmaLite, had proposed the replacement of the direct gas impingement system by a linked piston as early as 1969: it is the COLT 703. But this technological shift would undoubtedly have had “significant” logistical and financial consequences for the US Army… but would also have touched the self-esteem of too many people already buried up to their necks in this story. Make no mistake, it also works like that in administrations: again, experience is speaking. As another weapon better designed than the AR-15 but arrived a little later (such as the AR-18), the weapon was not retained.

Some other mechanical points

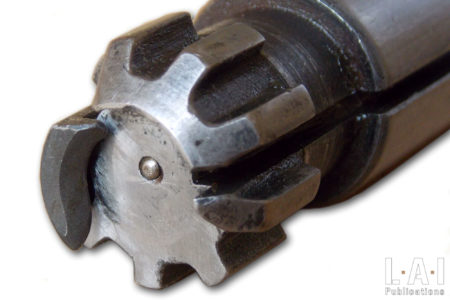

The design of the bolt is also not one of the best. This is once again an ease of manufacture: it is easy to make this part in machining, the lugs being made by a division in 8 of the circumference of the bolt, to which is removed 1 lug to allow the implantation of the extractor. As mentioned in Chapter 5 of the SGF (linked here), the number of lug has no relation to the strength of a lock. Only the total contact surface of the lock gives a first indication, a second indication being mainly given by their implantations on the bolt body: it is useless to draw a “wide” locking surface on a “fragile” bolt body. On this side, the AR-15 is once again not “in a very happy corner”: two of these lugs are located at the edge of the machining hosting the extractor: as a result, these lugs are frequently torn from the bolt (Pic.13). The lug supporting the extractor on Kalashnikov systems is hypertrophied in order to strengthen it: the design is so good that it will be copied including by SIG (SIG 540 and 550) and by FN Herstal (FNC and Minimi). And yet, by M.T. Kalashnikov’s own admission, the bolt of the AK-47 is inspired by that of the Garand. But the Soviet designer has notably corrected one of its defects: the fragility of the right lug through which … the extractor is implanted. Errare humanum est, perseverare diabolicum.

The design of the extractor is also not very fortunate: the desire to maintain its axis by telescoping the bolt inside the bolt carrier (to facilitate its disassembly) led to its ridiculously backward positioning and thus giving an important lever arm to the case against the extractor spring. Therefore, the extraction and holding force of the case is low, which can lead to many jams, both in extraction and ejection, the extractor having a leading purpose in guiding the ejection. It is to reduce this defect that the “stiffening insert” will be added, present inside the extractor spring (visible on Pic.09). It also prevents the “runaway” of the extractor, as does the shock absorber of the wheels of a vehicle. But the design remains bad: for the G36, Heckler & Koch will choose to move the axis forward, even if it means crimping its axis. Add to this that the weapon has no primary extraction…

The ejector is of a “spring loaded” type. Where some will sell the mastery of the power of the moderate ejection which integrates with less constraint the weapon to the warrior landscape (blah-blah-blah), I will argue that this is actually only an ease of production, once again. It is mechanically more “complex” than a fixed ejector (more parts), therefore less reliable (especially by the use of a spring’s power), but much simpler to install and cheaper to produce! Once again, why did E. Stoner set about making it disappear from the Stoner 63 and 63A? Because, learning from his “younger self’s” mistakes, he sought to make a weapon of “absolute” reliability. Errare humanum est, perseverare diabolicum. Too late for the US army who had “chosen” the AR-15… The evil will last for decades… and still persists as we write these lines.

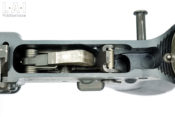

Regarding the firing mechanism, there is only little to say. The arrangement of the automatic sear is curious because at the rear and working on the crest of the hammer (Pic.15). Most of the automatic triggers of the other weapons work on the base of the hammer by being positioned at the front of the mechanism (path followed by E. Stoner with the Stoner 63, again). No impact? In the case of the AR-15, it is not certain: we will come back to this in a few lines.

The bolt carrier group is telescoped inside the stock at the time of firing: the recoil spring and the buffer are housed there. Here too, this provision is inherited from the weapons of Melvin Johnson… but it is also found on the Stg-44! First pitfall: goodbye O folding stock. Instead, the compact versions of the weapon that will soon see the light of day will receive a telescopic stock that is well known today. “Nothing more” you will tell me. Not sure.

Added the two elements previously mentioned, add a shooting incident involving non-closing of the bolt carrier group. What is the solution to resolve the incident?

- M16: you are desperately trying to force the BCG forward: back and forth movement with the charging handle for example, but it does not allow you to force the BCG forward. Indeed, the M16 does not have the “forward assist” of the M16A1 (insistently requested by the US Army – Pic.16). To solve your incident once and for all, you decide to disassemble the weapon. And there, surprise: disassembly is impossible without removing the automatic sear: the passage of the rear pin of the upper receiver bumps against the latter and the BCG is telescoped into the stock. You can’t resolve your incident quickly in the field. Stupid huh?

- M16A1: You force your forward assist to close the BCG. If you are not wise, it is to be able to shoot, until the incident occurs again or until your weapon explodes as mentioned above (just imagine that your incomplete closure is related to a bullet stuck at the entrance of the barrel… which is not as rare as one thinks…). If you are wise, you close your weapon, you disassemble it (because it is now possible), analyze and remedy the failure. After that, militarily speaking, one change the model of the rifle if possible.

Thus, the M16A1 differs – among other things – from the USAF’s M16 by the presence of the legendary “forward assist“, which can be used for the “tap, rack, kaboom”! The US Military then speaks of S.P.O.R.T.S. in the service manual:

- Slap up on the bottom of the magazine (while it is enough to pull it to check the hook … in short…)

- Pull the charging handle to the rear.

- Observe the chamber for an ejection of the round.

- Release the charging handle (it must be understood here that it should not be accompanied).

- Tap the forward assist (it is interesting to note that on the instructional video, the movement is not really brutal…)

- Squeeze the trigger again. (KABOOM!)

But it can also simply be used to force the closure of one’s weapon for disassembly. Others will say “it is used to secure the BCG after doing a loading check”: blah-blah-blah! With a double-fed type magazine, to check if one is chambered, simply remove the magazine after chambering to check if the ammunition in presentation have changed lips. The magazine is repositioned until locked and pull to check its attachment. No, we do not “slam” the magazine… It’s a moron’s movement… For the most skeptical: if the locking assistant is only used to close the last few millimeters to complete the lock… Why is the rack machined along the entire length of the bolt carrier (visible in Pic.12)? By the way, no, this rack does not scrape against the receiver and is not intended to “scratch” the weapon’s grim like the “sand-cuts” of some FAL…

The totally straight 20-round magazine, and devoid of curvature on its first part for the 30-round magazine is also a mechanical heresy (Pic.17). Even if the ammunition of 5.56×45 mm is barely conical on its body (which is rather a defect, because disfavoring the take-off of the case at extraction), a curvature of magazines is necessary, to optimize the introduction of ammunition at any time of the capacity of the magazine. At a minimum, it is necessary to “incline” the magazine relative to the axis of the barrel to promote the rise of ammunition to the chamber … But here, no. As a result, a boss at the outlet of the magazine, and a double feeding ramp on the barrel extension that says a lot about the path of the ammunition during its feeding phase (Pic.18). Well clearly, it is not the worst of this weapon and this conceptual “defect” (which is once again originally, an ease of drawing) is shared by other weapons. Service magazines also suffer from a deplorable fragility, which makes the happiness of accessories-sellers! But when it comes to reliability, failures come from the accumulation of factors…

The construction of the frame of the weapon in two aluminum receivers (lower and upper) linked by two pins is not the strongest and in fact, an “ordinary” shock (understand related to normal use) can cause damage prohibiting the use of the weapon, irreparably at the scale of a soldier. One must also forget the shooting of rifle grenades in a permanent way … even if it is touted by the advertisements of the time and by the ARPA reports! Here too, HK will do a lot of work to “solidify” the frame, especially the upper, so that it is able to fire rifle grenades durably as required by the specifications of the French Army. Just like the direct gas impingement, the use of aluminum alloy for the construction of a frame of a weapon of war does not find favor with our eyes…

Finally, in general, the weapon was not designed with the idea of accepting the presence of foreign bodies inside its mechanics (an obsession for M.T. Kalashnikov!). In other words, the parts lack room to move. Thus, the presence of foreign bodies even in small quantities results in jamming, because they are interposed between the parts or slow them. Particularly sensitive point, the housing of the recoil spring: an almost one-eyed housing which, if barely filled, considerably harms the recoil of the BCG. But the same is true for the firing mechanism. And once again, the models designed by E. Stoner after the AR-15 will all take this issue into consideration, in particular by ensuring the guidance of the bolt carrier group by the guiding rods and no longer by the receiver’s body, which leaves ample room to push back obstacles to the movement of the bolt carrier group. Some will argue that the AR-15 is “sealed” against fouling of external origin. Seriously? With a bolt stop at the end of the magazine? The real consequence of its “sealing”… it is especially that nothing comes out quickly! Here again, clearly not a good idea… Facing the water and desert’s sand, the only possible seal is that of a hermetically sealed cover… But some will argue, faced with years of problem with this weapon, that during the American engagement in Afghanistan, a reporter followed a team of Marines and found “almost no problem”… yes, the ARPA reports (the subject will be treated below) also indicate that users of the weapon have not encountered any problems. On the other hand, many internal reports emphasize that the weapon is not suitable for operational use, because it requires too frequent cleaning operations under penalty of jamming… The reality is in the overall mechanical analysis of the weapon that we have just made: to use an expression that is not ours, the AR-15 is a “pot-pourri of bad technical choices”.

Some additional thoughts on ergonomics

This is probably the most delicate point to discuss: it is partly subjective. However, some points are objectively open to criticism.

The charging handle is not the most rational design. It does not allow an easy forced opening (sometimes necessary) and does not allow forced closing at all as already mentioned. Its use is impractical, especially when prone. Remember that its positioning is related to the fact that during the first evaluation (which was totally disconnected from any adoption consideration), the soldiers of Fort Benning did not want the charging handle inside the carrying handle for fear that the soldiers would hurt themselves with it.

The magazine’s locking is not the firmest or easiest one. Its button is far too easy to access… including for something other than the user’s fingers. Some will praise the speed of reloading (blah-blah-blah… life is not a Chuck Norris’ movie), others will deplore the unexpected loss of magazines that it can bring, especially by the bad locking of the magazines when they are full. Bad locking? Yes, because the introduction and locking of the magazine is done by a push movement and not by a lever movement…again, in more detail in Chapter 6 of the SGF. This leads these users to frequently not load the last two (or even three) round to facilitate the locking of the magazine when it is replaced. Contrary to popular belief, ammunition, even during the Vietnam War, was not packaged in a magazine (the idea was undoubtedly studied, but not retained: it was simply necessary to imagine the financial and logistical consequences), but in cardboard boxes or on stripper clips. Magazines were never intended to be thrown away after use: their lifespan is simply shorter than that of the weapon because of their fragilities…

The presence of a bolt stop is not essential, these benefits are questionable. Do you really want to find yourself in the open bolt at the end of the magazine in a dusty/sandy country with wind? Are you really saving time replacing your magazine? Everyone is a judge, but I think not: and in my professional experience as a trainer, the majority of “normal” users are informed of the emptiness of their magazines by an unrewarded action of the trigger. Even with handguns and in peacetime! Is the absence of these devices on Stg-44, HK G3, FAMAS, Kalashnikov… also due to design errors? Certainly not, it is a reasoned and pragmatic choice. The most elegant solution is the G36’s where the bolt stop is de-activable. Finally, the manual implementation of the AR-15’s bolt stop is not easy. For our friend Pierre Breuvart, this bolt stop is in fact a palliative to the bad charging handle of the weapon: it actually makes it possible to put the weapon back into service more quickly at the end of fire. But was it thought for this purpose or is it the legacy of the American “habitus” in this matter. Everyone will have its opinion.

But there are still some to boast about the organization of the AR-15: from our point of view, it is not thought out well enough (and especially not for its general infantryman audience!), it is subject to constraints external to ergonomic considerations.

So why did the USA adopt such a weapon?

This record is not very glorious. Mr. Paul Tellier, father of the FAMAS even said (in essence) to Pierre Breuvart during an interview “how could a great country like this make a weapon like that? “. What combination of circumstances could have led a country like the United States of America to adopt such a device – in the midst of the Cold War? As always, everything needs to be put back in context.

The AR-15 has its origin in the AR-10, an automatic rifle in 7.62×51 mm that has not really found its military audience. This weapon was design by “ArmaLite”, a subsidiary of the Fairchild Engine and Airplane Corporation, created in the early 1950s by Richard “Dick” Boutelle, then president of Fairchild. The name of this subsidiary is derived from the words Arms-Light. And indeed, producing “light weight” individual firearms, using modern materials (aluminum alloy and synthetic materials already very present in aeronautics) is the leitmotiv of this subsidiary. Its director, George Sullivan, also was, before the creation of ArmaLite, a specialist in the use of alloys and composite materials at Fairchild. He recruited Eugene Stoner as a “Chief Designer”, whom he met, according to the “official legend”, on a shooting range and who presented him with a shooting rifle of his own making. It is from the meeting of these two men that will be born among other weapons in the mid-1950s, the AR-10 in 7.62×51 mm. To make it short: the materials are G. Sullivan, the mechanics are E. Stoner (and in his shadow Melvin Johnson, bien entendu…).

If the AR-10 has not managed to impose itself in the military world (in our opinion rightly, the weapon is not reliable), during various demonstrations it still managed to strongly impressed some people by its resolutely “innovative” aspects. Thus, the commander of the U.S. Continental Army Command (CONARC), General Willard G. Wyman, suggested to E. Stoner the creation of a weapon in reduced caliber (read here, close to .22 inches), following the precepts resulting from the study “Small Caliber High Velocity” (SCHV) then in progress. In 1957, it resulted in a first version of the AR-15 in… .222 Remington! Yes, no mistake, this is the hunting ammunition already available on the market. However, the caliber/ammunition pair does not fully meet the military requirements for ballistics at 500 yards (457.2 m). Thus, this couple will be reworked to become – after several nominal hesitation described in our article dedicated to this caliber – the .223 Remington, whose ammunition’s bullet with a brass-jacketed lead core weighs 3.5 g. Yes, we are still in civilian area, but it is the future 5.56 M193. At ArmaLite, the work on the reduction of caliber on the weapon will be the result of the work of Leroy James Sullivan (“Jim Sullivan”, future father among other weapons of the Ultimax 100 … article here!) and Robert Fremont. We will quickly point out the almost total absence of serious tests during the “research and development” phase of the .223 Remington, which is indeed the “5.56 M193” originally adopted by the US Army. From a ballistic point of view, E. Stoner only “redesigned” a .222 Remington for a slightly heavier bullet and a higher powder load, which led him, to avoid too much pressure, to increase the volume of the powder chamber by pushing back the collar. Despite this, the pressures remain high (higher than a M80 7.62×51 mm) … too important according to your servant.

At the same time, the Winchester firm will develop, also on the advice of CONARC, a prototype weapon called “Light Rifle” heavily inspired by the USM1, chambered for a caliber originally named .224 Winchester E2.

The two firms produced 10 weapons that were sent for evaluation (unrelated to a possible adoption, it was not a call for tenders) at Fort Benning in 1958. This is one of the few times the AR-15 will be measured against a weapon of equivalent concept. Once the conclusions of the tests were rendered (which therefore did not establish a “winner”, but produced recommendations), Winchester did not follow up on its work. The investments should have been substantial, and the firm had just won a contract to manufacture the newly adopted M14. The AR-15 will therefore find itself without competition. Because if for its part, the Springfield Armory will conduct some tests according to the SCHV concept, it will never offer a rifle for tests.

The way is clear, and from there, it is first of all lobbying and a combination of circumstances that will – from our point of view – do the rest. Because yes, what we offer here, more than a precise enumeration of the facts (which are already the subject of the excellent book “The Black Rifle” by R. Blake Stevens and Edward C. Ezell at “Collector Grade Publications”), is our reading of what happened in filigree of this story to lead to this “disaster” that never ends.

The AR-15 will enter the Great Family of the US Army through the “back door”: that of a direct purchase from the US Air Force. It is indeed the legendary General Curtis LeMay, friend of “Dick” Boutelle who will force for the weapon to be bought by the US Air Force. For the sake of intellectual honesty, it is important to clarify here that we could not determine what “Dick” Boutelle’s duties at Fairchild were after 1956: a legal document (linked here), indicates that he left the position of president of Fairchild in 1956. From January 1959 until October 5th, 1960, the president was James H. Carmichael. Subsequently, the position was taken over until 1962 by Sherman Fairchild, the founder of the company. There is therefore a doubt about Fairchild’s presidency between 1956 and the end of 1958. It must be said that this period was difficult for the aeronautical firm, the year 1958 having had a more than disastrous balance sheet. If we make this clarification, it is because the role of Richard Boutelle in this story is important, and that he is sometimes presented, wrongly according to our research, as president of the society on July 4th, 1960.

On this date, which is Richard Boutelle’s birthday, a demonstration of the AR-15 is organized at a party in his ranch (celebrating both Independence Day and his birthday), in the presence of General Curtis LeMay. Organized by whom? By Robert W. MacDonald, known as “Bobby MacDonald”, representing Colt’s interests at the time. This is the person behind the sale of the AR-15 patents to Colt in 1959. His company “Cooper-MacDonald” has an incentive up to 1% of future sale of the firm with the Prancing Horse… in addition to the $250,000 already collected (yes, much more than the $75,000 collected by ArmaLite). What demonstration? The shooting of two watermelons: one at 50 and the other at 150 … yards! For those who doubt it, beyond the “spectacular aspect of the thing” (a watermelon is actually only a “big bag of water”, so something incompressible that bursts on impact), there is no technical relevance of the exercise. This anecdote, initially told by Bobby MacDonald himself, is not trivial: because it is General Curtis LeMay who will force the USAF to buy and adopt the M16. How can we not see here a first deafening sign of connivance or lobbying. As we have no material evidence at our disposal, we cannot speak of corruption: it is a very different legal fact, and therefore an accusation not to be made lightly. Finally, for our part, the origin of the anecdote being Bobby MacDonald… Well, we have limited trust in it.

Returning to the charge three times from the highest levels of the state, General Curtis LeMay will obtain the first purchase for endowment on May 23rd, 1962: 8500 AR-15 for the USAF, with spare parts and 8.5 million cartridges ordered from Remington. While it is sometimes mentioned that this order was supplemented by weapons for military advisers deployed to Vietnam, South Vietnamese troops, and Navy SEAL units (for a total of 20,000 weapons), this part of the order is not mentioned in the 1967 Ichord Report.

This purchase was preceded only by the purchase – obtained by Bobby MacDonald – of 1000 weapons on December 27th, 1961 (so about 6 months earlier) under the experiment organized by the “Advanced Research Projects Agency” (ARPA). ARPA, a Department of Defense agency created in 1958, was entrusted with the “AGILE Project” between missions, having to evaluate the compatibility between the AR-15 and the “small and light” stature of Vietnamese soldiers. The AR-15 will then be mainly compared – including in combat – to the M2 carbine in .30 Carbine caliber, but also to the M1 Garand, the BAR 1918 and the Thompson M1A1 SMGSubMachine Gun More. Unsurprisingly the AR-15 will be preferred to all other weapons on practical considerations. A report on the ballistic effects of the .223 Remington (the name 5.56 does not yet exist) will also be produced. This report, whose conclusions, more than ravenous, raise questions because the effects described could never be reproduced by the army laboratories (at the Edgewood Arsenal as soon as 1962) in the months that followed…. In addition, this report refers only to bullet engagements at distances of 100 m or less. In the wake of ARPA’s work is… “Bobby” MacDonald! And yes, him again! When we look at the distribution and endowment of these weapons: 965 rifles were distributed with 550,000 rounds of ammunition… Yes: about 570 rounds of ammunition per weapon. And the detail of this distribution is even more distressing: the best endowments being 1000 and 960 rounds per weapon (“Special Battalion” and for the fighters of Nguyễn Lạc Hoá, known as “Father Hoa”), the other endowments being about 500 rounds per weapon. Which clearly, in the context of an evaluation, is insufficient to determine anything… Finally, regarding the timing of this “evaluation”:

- The first weapons were delivered on January 27th, 1962.

- Testing began on May 1st, 1962 (22 days before the order obtained by General Curtis LeMay).

- The balance of arms was delivered on May 15th, 1962.

- The tests were concluded on July 15th, 1962 (so, about 2.5 months…).

- The report was delivered on July 31st, 1962.

It is clear that these tests cannot have had a significant impact on the May 23rd, 1962, order: the endowment objectively does not allow it, nor the duration of the test.

Regarding the infantry rifle, the US Army, which had adopted the M14 in 1957, had at the same time “bogged down” in ambitious programs: the SALVO and SPIW projects. The purpose of these programs was to provide a weapon/ammunition pair, with a very high hit probability. All while potentially using multi-projectile munitions (rather the prerogative of the Salvo project, including its duplex and triplex ammunition) or very high muzzle velocity darts (rather the prerogative of the SPIW project, but there are also dart ammunitions in the SALVO project). All these projects were based on very comprehensive statistical studies of feedback from previous wars. These programs, very interesting and legitimate in absolute terms, were failures insofar as they did not allow the adoption of the “miracle solution” expected by the army in the form of a weapon / ammunition pair. It can be noted, while we’re at it, that this is often the case with these ambitious programs: it will be the same with the “Advanced Combat Rifle” (ACR) program, which not content with leading to no adoption, almost cost the life of the Heckler & Koch company with the development of the HK G11. The expectation of this “miracle” weapon made – among other considerations – the Bundeswehr, did not want to switch to 5.56×45 mm until the 1990s with the adoption of the G36: quite the irony for the country that saw the birth of the “Strumgewehr”. In France, we could also talk about the Felin program, whose small caliber component is generally concluded by the destruction of the Felin FAMAS with the arrival of the HK 416 F… But back to our (black) sheep.

Along with these programs, the U.S. Army faces serious M14 procurement problems. It thus finds itself relatively destitute in terms of “modern” infantry weapons adapted to the realities of the ongoing fighting. At the beginning of their deployment to Vietnam, the American troops counted among their very heterogeneous inventories of the BAR LMG and Thompson SMGSubMachine Gun More, both designed at the end of WWI. On the North Vietnamese side in the early 1960s, the situation was not necessarily better: many bolt-action rifles (Mauser & Mosin Nagant) rubbed shoulders with many submachine guns from the last war (and some MAT-49s captured from the French). But soon, RPD-44s, SKS-45s, AK-47s and even AKMs would arrive in large numbers, all in 7.62×39 mm. And the Americans knew that.

Finally, it is necessary to note that it was during these years that the administration led by Secretary of Defense Robert S. McNamara had obviously decided to put an end to the “state-owned” small arms industry (the word is undoubtedly strong about the United States compared to what we experienced in France). Announced in November 1964, this will conclude with the closure, on April 30th, 1968, of the “Springfield Armory“. It is not a question of “privatization”, but of the plain and simple destruction of a public institution, the vacuum left to be filled by private industry (this is undoubtedly an ideological rather than pragmatic consideration). It must be understood here that the Springfield Armory was not a simple production site, but one of the hearts of the military industry of small arms in the United States. Its closure led to a loss of knowledge and critical eye on the small caliber weaponry from which the United States probably still suffers – in our opinion – today, despite excellent weapons experts… (but also a bunch of pretentious assholes…)! We French, know this disease well, we suffer from the same …

The pieces of the chessboard are in place, and meanwhile, the “matchmaker” Bobby MacDonald, activates his networks to push for the purchase by the army of the weapon then produced by Colt. How can we blame him: it’s his job!

At the beginning of the 1960s, the situation was therefore complex for the American Army, whose deployment in Vietnam intensified. It is in urgency, to fill a void left by the lack of supply of M14, that it falls back on the “revolutionary” weapon acclaimed by the USAF. It thus buys “off the shelf” on November 4th, 1963, (called, ironically, a “one time buy” or “on time procurement” contract) 85,000 “XM16E1” (temporary name of what will become the M16A1, the X being the reserved for of weapons in experimentation) as well as 19,000 M16 more for the USAF. The purchase is then thought of as temporary, until the SPIW program gives a result. But after successive amendments to this “one time procurement” contract, in March 1966, nearly 419,227 were ordered. These purchases will be made despite the many problems already clearly identified and denounced by various reports and specialists of the military institution.

On February 28th, 1967, closing out on all of these wanderings, the US Army “regularized” the status of the XM16E1 (then the most distributed weapon to American soldiers in Vietnam) within its troops by an official adoption, under the designation “US Rifle, 5.56 mm, M16A1“. The weapon, which is still not reliable, will not stop causing problems for the US Army.

Thus, there has never been a “call for tenders”, with a competition between the AR-15 and rifles of different brands for adoption by the American armies. During the various “tests” carried out during this period (and in particular the “World Wide Trials”), all comparisons will be made with the M14 (a “Battle Rifle”) and the AK-47 (the enemy’s weapon). It should be noted here that the documents we are aware of do not specify whether it is a question of AKM or really AK-47: given the time, the question is nevertheless totally legitimate, the two weapons having significant differences. The tests would never really focus on long-range effectiveness (we often talk about efficiency below 100 m), biased the tests of exposure of the barrels to water (by drainage out of the barrels before firing), would take into account the doubtful ARPA reports more than Army tests.

Facing the M14, the AR-15 would be considered “more capable” tactically for “modern” combat: how could it have been otherwise? The M14 is not an assault rifleAn assault rifle is a weapon defined by the use of an "inter... More! The weapon is heavy, with a much more powerful ammunition, and a consequent recoil. The real comparison should have been made with other assault rifles in 5.56 mm (or similar caliber), sold by other firms.

But no, for Armalite as for Colt, the financial interest is to highlight the AR-15. Colt to absorb its purchase and avoid getting lost in research and development, ArmaLite to receive Royalties.

For American soldiers, in Vietnam then in Somalia, Iraq and Afghanistan (and some I forget): come what may… And when we criticize this weapon here, we think of them first and foremost.

From our point of view, the military survival of the “Stoner” system of the AR-15 until today in different forms (M16 and M4 families) is due in a major way to its nationality of origin and production: the frenzied economic protectionism of the United States has allowed the national contractors who manufacture it (Colt was not the only manufacturer of the weapon, U.S. laws favoring the plurality of U.S. suppliers for service equipment) to supply a significant amount of this equipment to the U.S. military, but also to countries receiving U.S. aid. Indeed, the Americans are much more willing to provide equipment manufactured on their soil, than dollars whose final usefulness is not certain… From the point of view of the producing country, one can only understand this approach, especially given the capitalist and ultraliberal ideology. The Soviets, on the other hand, would make massive use of technology transfer…think different.

To compensate for the defect of the weapon, cleaning operations would be intensified and the purchases of spare parts would be disproportionate to say the least: for years, the Hartford firm would owe its survival mainly to the substantial contract in spare parts obtained by the army…

What positive things are there for this weapon?

From the point of view that interests a majority of our readers, that is to say the civilian weapon enthusiast’s, it is historical: it is the American rifle of the Cold War, much more than the M16A2, which in addition still sports the same defects.

From a mechanical point of view, the AR-10 / AR-15 use an interesting mechanical device: the firing pin is carried by the bolt carrier and not by the bolt. This brings two benefits:

- The firing pin is held back from the ammunition when the bolt is unlocked (but it does not prevent “slam fire”).

- The firing pin is mechanically peeled off from the primer during the unlocking phase.

The device is not a weapon innovation: we already found it on Melvin Johnson’s M1941 rifle… but also on the French FSA RSC M 1917 then MAS-49 (and their descendants)! But mechanically this remains a good point…one of the only ones left.

The AR-15 family is pleasant to shoot with. The accuracy, often bragged as excellent, is actually in the norm of other western military 5.56×45 mm rifles: that is to say good for a weapon of war. Some other assault rifles sometimes even offer greater intrinsic accuracy than the AR-15 produced for the military market thanks to a better quality service barrel. Even with Kalashnikov mechanics… we are thinking particularly here of the Valmet M76 (article available here). It is the 5.56×45 mm caliber with good ammunition which allows good results in shooting … and not a specificity of the AR-15. In addition, the sights are not quick to adjust the sport shooting, because they are only oriented towards combat shooting with one aperture for the distance 0-250 m and a second to push up to 375 m. Be careful, this choice is rational for military use and does the job. It is also necessary to relativize this notion of “accuracy” by framing it in its military use: at equivalent ammunition quality, we do essentially the same work from 0 to 300 m with a Kalashnikov in 7.62×39 mm and from 0 to 400 m with one in 5.45×39 mm: that is to say 100% of hit probabilities in a human silhouette.

Similarly, its shooting behavior is good without being significantly better than that of other rifles in 5.56×45 mm. The second part of our article on “Assault Rifles: how they behave” details this more deeply. Moreover, during the evaluations that took place in 1962 and comparing the weapon to the M14, the burst would be judged as having a “low effectiveness” for both weapons.

Its disassembly is relatively easy, especially compared to the weapons in the US Army at the time (Pics. 19 & 20). Its cleaning is not the most laborious in terms of accessibility… it is still much worse than on other weapons including the AK family. On the other hand, as already mentioned, the system clogs considerably the inside of the weapon …

With the reservations already issued, it is rather light, it is the strongest point of the rifle from a military point of view. The first thing a soldier does with his weapon is indeed to carry it! The second thing is to clean it (the American manual in the form of comics (available at the end of the article) from the Vietnam era recommends, on page 7, to clean the weapon 3 to 5 times… per day…).

Its aesthetics will not please everyone, but personally we find it rather beautiful, especially the M16 and M16A1 with the triangular handguard versions. The ammunition is easy to find commercially (be careful, use of M193 type ammunition only for the M16 and M16A1). Finally, for those who enjoy it, the weapon is “customizable” by the multitude of accessories-sellers who have looked at how to improve (or pollute) the weapon.

Finally, a positive point not palpable for the shooter, but consistent on a government scale: it is rather easy and inexpensive to produce. This was also emphasized in its comparisons with the M14.

In conclusion

Some will accuse us here of making a “vitriolic” portrait of the weapon dear to their heart. In reality, we are only factual here. If the AR-15 met a “need” at some point in the history of the United States of America, its technical choices are mostly bad and have dramatic consequences in terms of employment. Similarly, the sequence of events leading to its adoption can in no way claim to be a victory in a particularly difficult competition. Quite the contrary. Objectively, it is a poor weapon of war. If it can still fulfill its military role today, especially in modern conflicts called “asymmetrical” where infantry combat is not the “center” of the war system, it does not stand the comparison with almost all of its contemporaries in terms of reliability. Ok, there is the case of the L85A1, but here too, one must place the weapon in its production context… and some parallels can even be drawn with the history of the AR-15! In any case, reliability is the first thing we ask of a weapon of war. Finally, the AR-15 belongs more on our civilian shooting ranges than on a battlefield.

Arnaud LAMOTHE

Selected bibliography:

The Black Rifle: M16 Retrospective by R.Blake. STEVENS and Edward.C. EZELL

The World’s Assault RifleAn assault rifle is a weapon defined by the use of an "inter... More: Gary Paul Johnston and Thomas B Nelson

Assault RifleAn assault rifle is a weapon defined by the use of an "inter... More by Maxim POPENKER and Anthony G. WILLIAMS

An American Rifle: A biography, by Alexander ROSE.

The Black Rifle II: The M16 into the 21st century by Christophe R. BARTOCCI

Ichord report

Many manuals and documentation from the US Armies.

Someone still here?

If you are skeptical reading this article (and I understand you, it goes against 60 years of Soft Power), look at the circumstances that pushed Heckler & Koch to produce the HK416: this is an admission of the American authorities. For the record, the HK416 is not an M16, it is a G36 (which remains one of the best assault rifles in the current “western” market) imprisoned in an AR-15 body, whose prerequisites require it to keep some flaws, such as the 7-lug bolt instead of the 6-lug of the G36, better designed in many respects and stronger as a result. Finally, ask yourself the question of the impact on your mind of movies and video-games production including AR-15 … It is a form of propaganda whether we like it or not, because it rarely reflects reality.

Finally, contrary to what can sometimes be read on the internet about the G36 gas system: NO, the AR-18 was not directly designed by E. Stoner (he no longer worked at Armalite), who did not invent this gas system. This is the one already found on the AVS-36, SVT-38 and derivatives (in addition, the Germans had already copied it for the G43). We believe that its invention is earlier and not necessarily Soviet, but we cannot name an earlier model than the AVS-36. The G36’s (as well as the 416’s) is very different in the details because intelligently improved to regulate the pressure and reduce fouling as much as possible. And details matter in mechanics!

Annual subscription.

€45.00 per Year.

45 € (37.5 € excluding tax) Or 3,75€ per month tax included

- Access to all our publications

- Access to all our books

- Support us!

Monthly subscription

€4.50 per Month.

4.50 € (3.75 € excluding tax)

- Access to all our publications

- Access to all our books

- Support us!