Ultimax 100: between two worlds

When talking of “Light Machine Gun”, one can wonder what is this all about? Does it mean the weapon is light weight? That it’s referring to a “small caliber”? That it has a special light support purpose? In fact, these three things are most of the time connected to each other. Indeed, this naming question is a good one: and as time marches on, we saw even more names to be used: LMG, GPMG, Automatic Rifle, SAW and now IAR. Some weapons belong to several categories…and why not to all of them! And then, there are some UMGO: Unidentified Machine Gun Objects. The Utlimax 100 is definitely one of them.

A little bit of history…

Little is known on the genesis of this project, which would have started in 1978. This lack of information probably stems from the fact that Singapore is far away and interests very few people… and that is a shame really! Their approach to armaments is highly interesting and their production more than correct regarding international standards. To date, we have studied three of their weapons: the SAR-80 (the review is available here), the Ultimax 100 and the SR-88a, the reviews are yet to come. Production is not only oriented towards their internal market, but also towards export. We owe to this vocation the presence of these weapons in the conflict in the former Yugoslavia, which allows us to date their studies. This vocation also dictates the need to produce economic weapons and undoubtedly with a more “ephemeral” vocation than some European productions.

Once again, Charted Industries of Singapore (C.I.S., now S.T.K.) hired an experienced foreign designer. Piloting the project, we thus find L. James Sullivan, who previously worked at Armalite, especially on the famous AR-15. His mission: to make a weapon without any real equivalent on the market: between an assault rifleAn assault rifle is a weapon defined by the use of an "inter... More and a light machine gun. To find conceptual similarities with weapons that have existed on the market, we have to go back to the Stoner 63A in its “Automatic Rifle” version or even… to the CSRG-15 Chauchat! But we are talking here only about conceptual similarities: neither the Stoner 63A nor the Chauchat has characteristics transposable with the Ultimax 100. At the time of its release, the Utlimax 100 was a product without equivalent on the market… and this is still – to our knowledge – the case at the time of writing. If some weapons have been studied – or even prototyped (we are thinking here of the Surefire RGX, designed by the same J. Sullivan) – none have been put on the market.

Given Jim Sullivan’s curriculum vitae, it is not surprising to find similarities with the weapon of the Californian brand: the design of the bolt head is extremely close (the design of the locking lugs, extractor and ejector assemblies are identical), and the magazine is a derivative that varies only by its locking mechanism (we will come back to this point). These choices are not surprising or inconsistent with the manufacturer’s approach. Indeed, we find the same type of bolt head (with some interchangeable parts) and the same magazines on the other weapons of the brand. A coherence of the range in a way.

The weapon thus designed operates from an open bolt, works by with a short stroke gas piston with rotary locking with 7 lugs, is supplied by magazines and has (excluding Mk-2 variant) a quick barrel change. For details on these different provisions, we invite the reader to consult chapters 5 and 6 of the “Small Guide for Firearms” available on the same website. Our copy of the weapon has only one firing mode: automatic. This is the case for the majority of variants of the Ultimax 100, although one can mention here that the Mk-5, proposed to but not selected by the US Marines, also offers a semi-automatic mode.

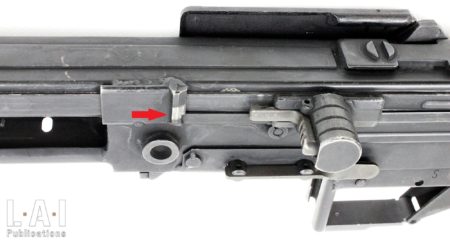

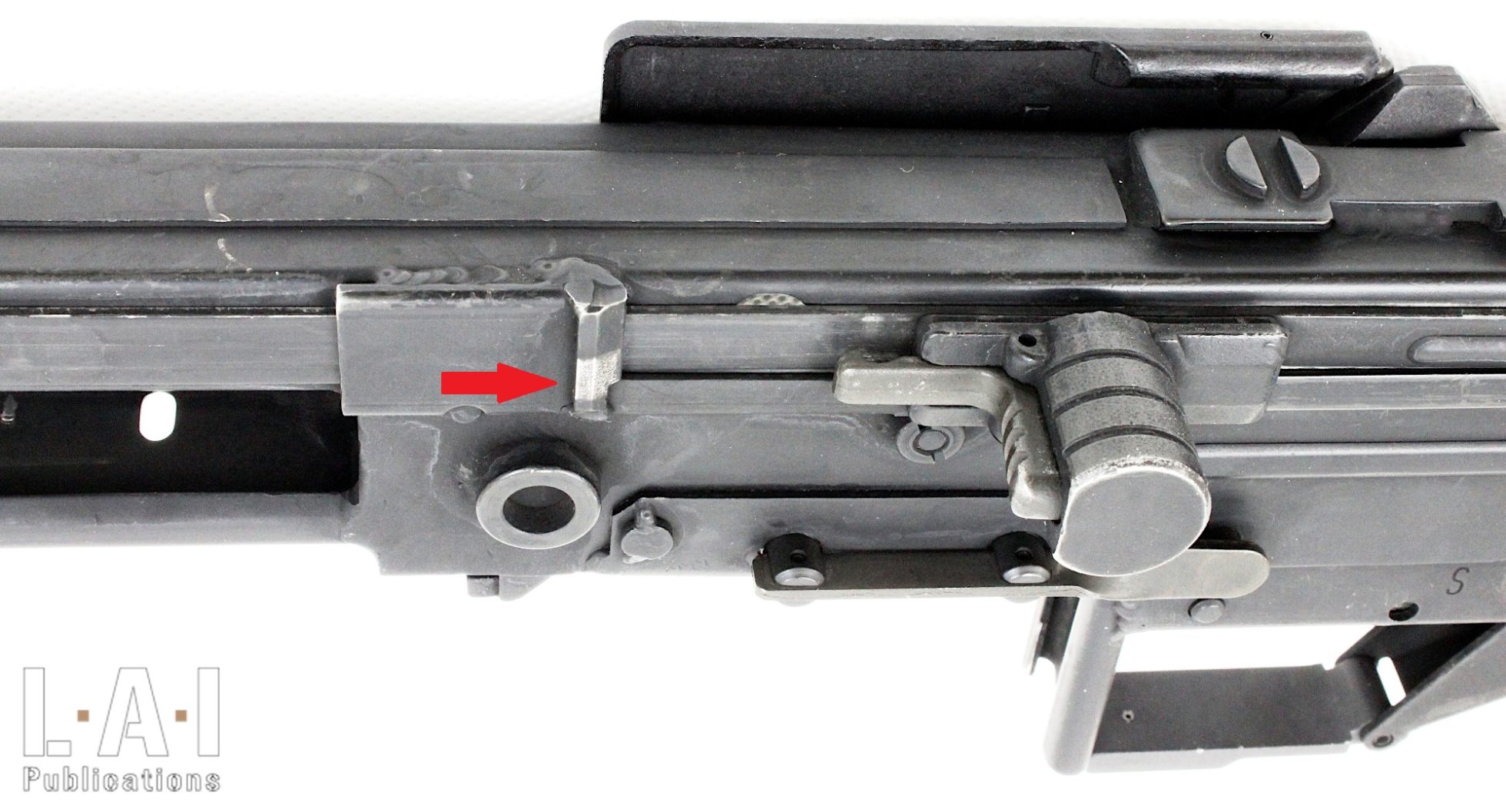

The implementation of the weapon is quite “classic”. There is a cocking handle on the left side. This one is of a non-reciprocating type. It has a retention hook which immobilizes the cocking handle when firing (Pics. 05). The magazine release button is positioned on the right side of the weapon like on an AR-15. The weapon is equipped with a safety at the thumb level on the left side of the weapon. The ejection port can be closed by a self-opening polymer dust-cover (Pic. 06). The whole is completed by a removable bipod, a front grip and a stock … which is removable and non-folding (Pic. 07)! The trigger guard can be lowered in order to enable this operation of the weapon with winter gloves (Pic. 08).

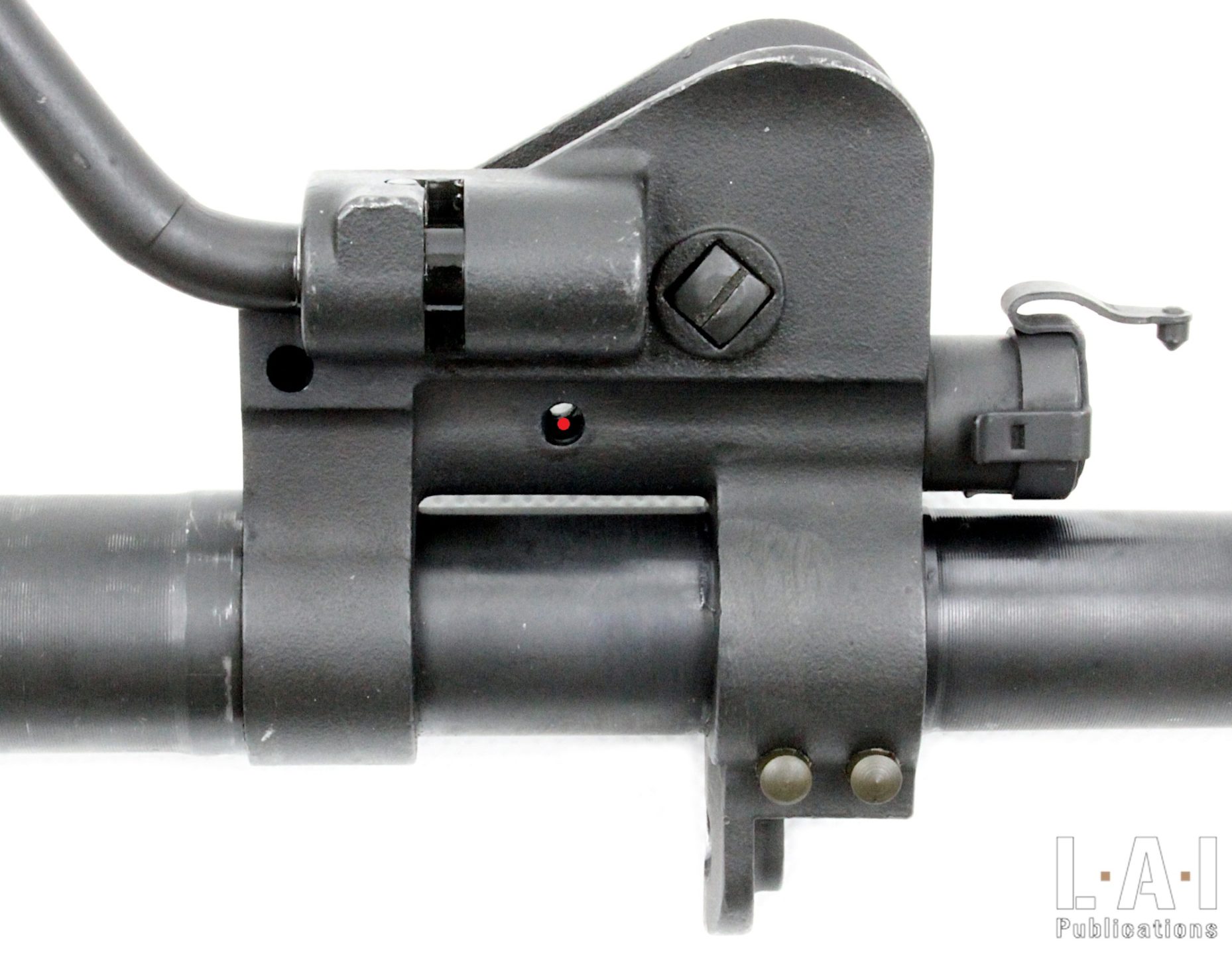

In the extension of the front grip there is an ersatz of a trigger which constitutes the control of unlocking the barrel (Pic. 09). The weapon can be equipped with two barrel lengths, 508 and 330 mm, which exists in both twist rate 1:305mm (1:12″) and 1:178 mm (1:7″) respectively optimized for M-193 and SS-109 ammunition (Pics. 10 and 11). These barrels carry the gas block, the piston and a regulator (Pic. 12). The latter has 3 positions to vary the quantity of gas taken according to the ammunition and the conditions of use. This regulation is carried out by varying the diameter of gas intake on a rotating nozzle (Pic. 13). They also have a carrying handle in two positions: on the side for shooting and on the top for movement (Pic. 14). This handle can also be used to remove a hot barrel when replacing the barrel. The weapon was presented with the bayonet tenon that allows the mounting of bayonets compatible with the M16.

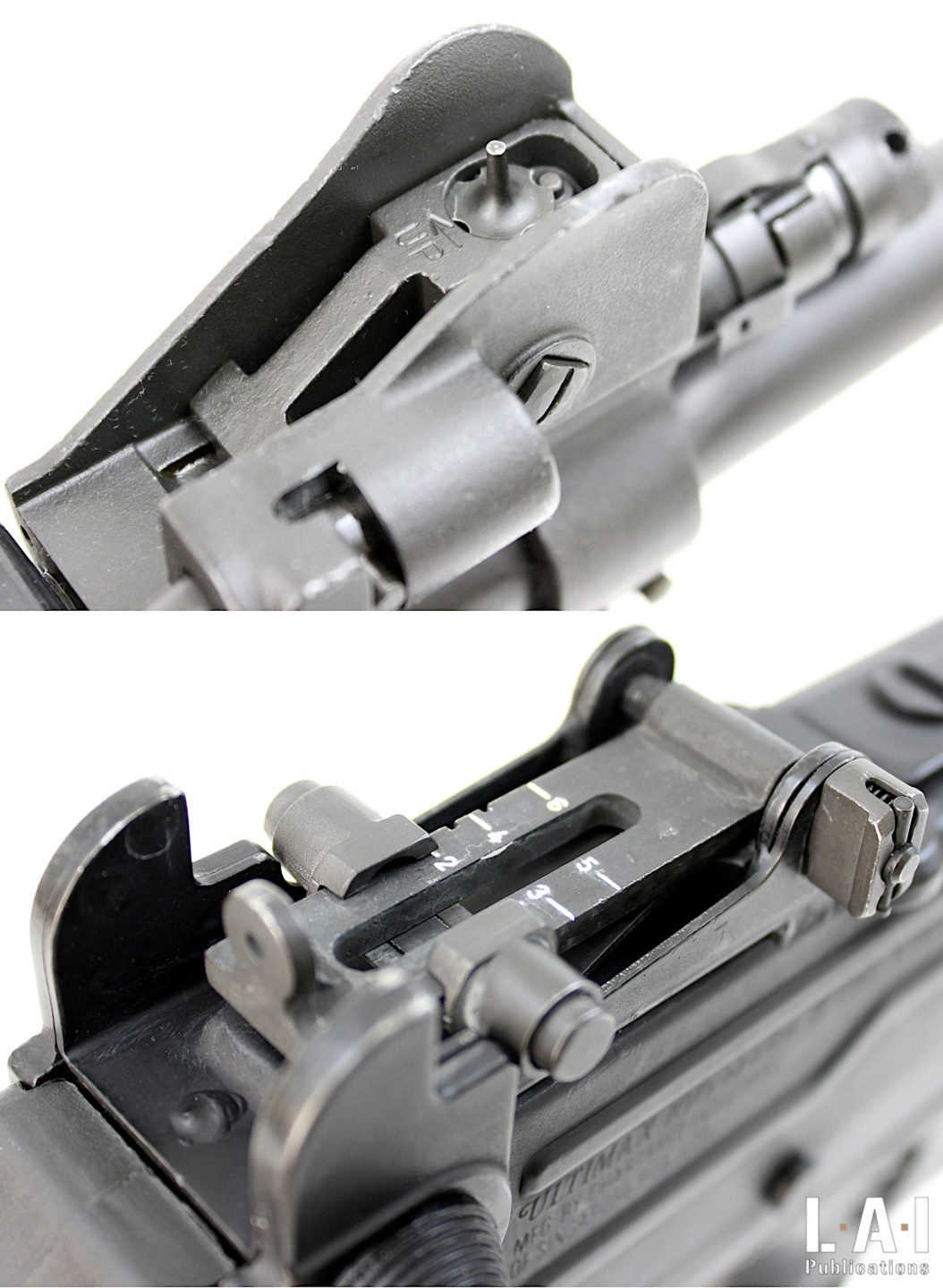

The sights consist of a rear sight aperture and a front sight post (Pic. 15). The front sight is attached to the barrel. It is adjustable in both elevation and direction, which keeps a clean setting for each barrel. The rear sight is adjustable by 100 m increment from 100 to 600 m for the M-193 versions and from 0 to 1000 m for the SS-109 versions. The rear sight direction can also be set without tools, probably to integrate shooting parameters such as wind or the consideration of a moving target. There is a proprietary rail for optics on the frame: the same as on the other weapons of the brand of the same period (Pic. 16).

…some mechanical insights…

The similarities with the Californian weapon, actually not so numerous, should not overshadow the bold and intelligent choices that make the Ultimax 100 an atypical and effective tool.

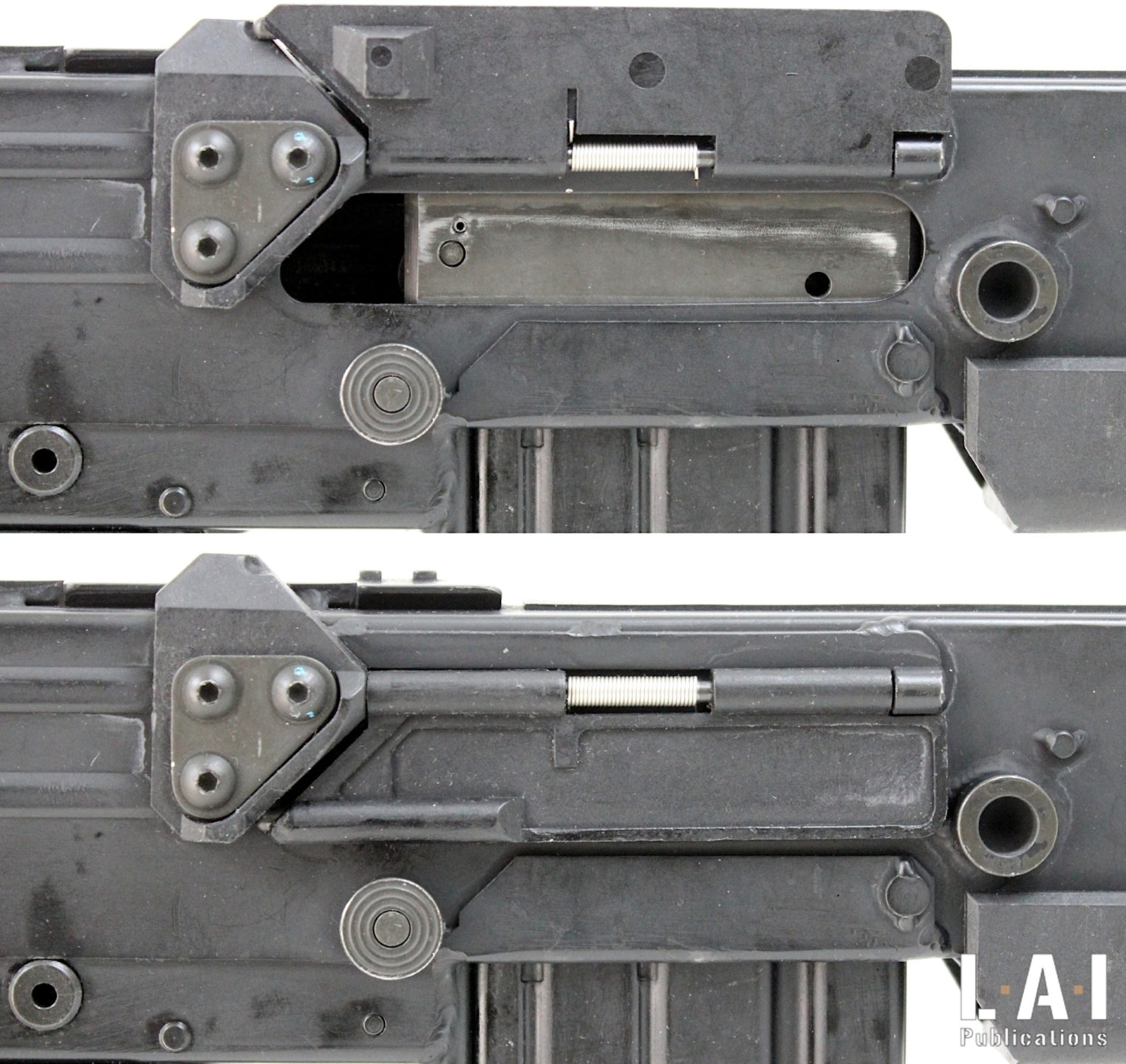

Unlike most weapons dedicated to automatic shooting, it was chosen here to obtain a low cyclic rate. About 400 to 600 rounds per minute, where the majority of LMG are greater than or equal to 700 rpm (including in this case, the “Automatic Rifle” version of the Stoner 63A). The technology used to “drop” the cyclic rate is simple, but oh so intelligent: the stroke of the bolt carrier group is very long and therefore takes “a lot” of time. To do this, and in order not to make an “extended” frame, most of the bolt carrier group mass is arranged on top and in front of the bolt carrier (Pic. 17)… which is what a long stroke (and thus linked) piston gas operated weapon does naturally! We can draw a parallel here with the trend of the so-called “telescopic” bolt for SMGSubMachine Gun More (Vz.23, UZI, Berreta 12SD, Vz.61 …), which aims at the compactness of the weapons by encompassing the mass of the breech around the barrel on the front (incompressible) portion and the weapon. The recoil spring is also of considerable length. The purpose of this provision is to dampen the rear movement of the bolt carrier group (one of the components of the “movement” of the weapon at the time of firing) in a very progressive way using a “soft” spring and thus avoid a sudden stop to the back. All of these provisions within this weapon are sometimes called “constant recoil”… in our opinion, a terminology that is more commercial than technical! For the record, we can break down the movement of the self-reloading weapon at the time of firing as follows: movement of the firing parts, recoil related to the start of the shot, rear movement of the breech assembly, damping, if necessary, of the breech assembly, forward movement, front stop of the breech assembly.

The choice to fire an open bolt impacts the weapon in several ways:

- This can greatly simplify the design and manufacture of the weapon and lower production costs. Obviously, this possibility depends on certain adjoining technical choices, but when the percussion is directly related to the movement of the breech assembly (with a striker linked to it), then the mechanics are simple and reliable. Simple because it only needs fewer parts, reliable because, in addition to a small number of parts, the percussion power is great due to the mass and speed of the parts at work. This is the case here: the striker is directly linked to the bolt carrier and automatically protrudes after locking the bolt (Pic. 18).

- This makes it possible to exclude the “cook-off” problem exposed below. You can also refer to section II-C of Chapter 6 of our book “Small Guide for Firearms” online on our website.

- This improves the cooling of the barrel between shooting phases by internal ventilation via the open chamber. If this phenomenon is to be relativized in terms of efficiency, there is no denying the fact that a barrel thus “ventilated” cools faster than a barrel “closed” by a cartridge.

- In the case of this particular weapon, this allows by the inertia of the front movement of the bolt carrier group, to compensate for part of the recoil related to the shot. This point is detailed below.

- This poses a reliability risk, as the ejection window remains open between shots, allowing the entry of foreign bodies. The dust-cover thus makes a lot of sense. It is also noted here that even in the closed position, there remains a significant opening through the ejection port, at the rear of the bolt conveyor (Pic. 06).

- Accuracy can also be affected. When firing, the delay between the triggering of the shot and the percussion is longer and involves more mass than in a system that shoots from a closed breech via a striker or a hammer. This may result in a deflection at the time of shooting. If this type of firing-system is objectively more difficult to handle than a system that shoots from a closed breech, obtaining good results is quite possible, especially for a duly trained shooter … Moreover, this depointing only affects the first shot on a burst: in the case of the Utlimax 100, the “burst” vocation of the shot makes this defect of a lesser importance.

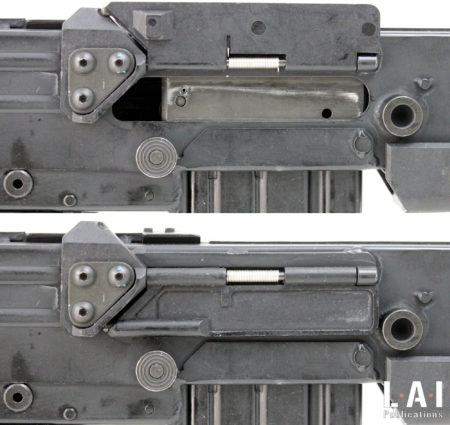

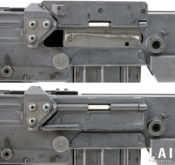

The design of the bolt also uses a significant counter-mass (77 g of the 564 g of the bolt carrier group or nearly 13% of it) housed in the upper part of the bolt carrier (Pic. 19). Pushed backwards by a spring, it allows at the closure to counter the phenomenon of bolt bouncing (called “elastic rebound”) but also to postpone part of the inertia transfer of the forward movement of the moving assembly at the time of firing, precisely in order to balance the forces at the time of setting the bullet in motion in the barrel. Let us not forget here that part of the energy of the bolt carrier group is used for the firing of the ammunition. This is reminiscent of the work carried out by the Russians on balancing the moving masses on the AEK-971, AK-107 and AK-108. Carried out in a more complex way on Russian weapons, the goal was also to improve the stability of these assault rifles in automatic fire. We note that the design of the Ultimax 100, probably less efficient than that of the Russians, is above all much simpler and more pragmatic! It should be noted that the work of the Russians has so far not led to any adoption, the results being below expectations.

The firing system, although simple because it uses the setting in motion of the bolt carrier group, has a necessary refinement. Indeed, on this type of weapon, it is often necessary to avoid the damage related to a partial rise of the sear when interrupting the shot: a partial clash would quickly result in a tearing of material related to the impact of the bolt carrier group on a partial surface of the sear. Here, the sear is held in the cleared position once the shot is triggered by an additional part related to the trigger. To erase this part and interrupt the shot, it is then necessary to completely release the trigger, which ensures the return of the sear to the initial position in a single movement. A device with a similar purpose is present on the firing systems derived from the MG-34: MG-42, but also AA-52, AN-F1, MAG-58 and Minimi. It is likely that this system was originally inherited from the MG-30… On these weapons, when the trigger is released, the rise of the sear is controlled by the movement of a “sear hook”, itself activated by the movement of the bolt carrier group. This makes it possible to control the exact moment when the trigger re-catches the bolt carrier group and therefore to present a total stop surface. The device of the Ultimax 100 is less accurate, but nevertheless the rate of fire does not require such precise timing: the trigger has “time” to go up more quietly … On weapons using the firing system of the MG-34, the rates of fire are usually twice as high and have bolt carrier groups of considerable mass.

The frame is built of stamped steel sheet, a pragmatic choice in terms of production that was also made to manufacture the SAR-80 at the same time. We find only marginally the use of aluminum, with the notable exception of the brand’s 20 and 30 rounds magazines (Pic. 20). The 50 and 100 rounds drum magazines are made of polymers with a transparent back allowing a visual on the contents (Pic. 21). On these drum magazines, the feeding is only on one side (left) (Pic. 22). The frame is painted black (probably after phosphatation), the rest of the pieces are phosphated. The piston and the regulator nozzle as well as the barrel interior (both chamber and bore) are chrome plated.

… and a lot of concept!

If there is a machine gun that deserve to be called “light”, it is indeed the Ultimax 100: 4.90 kg for the Mk-3 version subject of this article, with its 508 mm barrel and bipod. It thus “look down” on the FN Minimi as it nearly weighs 2 kg less. An important criterion. But is it legitimate to compare toe to toe these two weapons that seem to share at first glance a common use? The answer is clearly: “Nope”. Would it be more accurate to compare it to an RPK-74 or any other hypertrophied assault rifleAn assault rifle is a weapon defined by the use of an "inter... More, which, at equivalent weight, also shares the use of a magazine case instead of a belt feeding system? The answer is more nuanced, but ultimately is still negative.

The Ultimax 100 is clearly takes place between these two types of weapons: it is not a hypertrophied assault rifleAn assault rifle is a weapon defined by the use of an "inter... More (RPK-74, MG-36, FALO…) nor a “Mini-Machine Gun” as the MiniMi (Mini-Mitrailleuse in French) claims to be. It is a “multi-purpose” weapon: support / assault. In the end, the weapons that most closely resembles the Ultimax 100 are as mentioned above the “Automatic Rifle” version of the Stoner 63A, and of course the prototype Surefire MGX, which is very close in spirit to the Singaporean weapon. The Utlimax 100 can deliver effective (burst) support shots over engagement distances greater than what is achievable with an assault rifleAn assault rifle is a weapon defined by the use of an "inter... More, but also integrates perfectly within the military organization for assault phases. As a result, it would be closer to a hypertrophied assault rifleAn assault rifle is a weapon defined by the use of an "inter... More than to a “Light Machine gun” of the FN Minimi type. However, the choice to keep an open bolt firing weapon that has a quick barrel replacement capability makes it a more capable weapon for support shooting than a hypertrophied assault rifleAn assault rifle is a weapon defined by the use of an "inter... More (closed bolt shooting, fixed barrel for most of them).

Why more suitable for this type of shooting? The mere fact of operating a weapon intended for high volumes of burst fire from a closed bolt is nonsense. Indeed, firing a closed bolt weapon (where the ammunition is chambered before triggering the firing) condemns the weapon to a “cook-off” threshold: the ammunition chambered in an “overheated” barrel is fired by the thermal inertia of the latter. By overheating, we mean precisely that it exceeds its “cook-off” threshold. This “cooking” is all the more treacherous, since contrary to some belief, it does not intervene immediately at its chambering but generally in a delayed way (which can exceed several seconds) and even repeatedly! You stop shooting and a few seconds later, a shot is fired without you having wanted it. This is very problematic, especially in a warlike context: the military forces may be in a phase of movement that involves comrades being in front of the line of fire of your weapon. If compliance with the safety principles is sacred, it is however foolish to think they can be perfectly maintained in the chaos of fighting… The open bolt firing system avoids this problem. Also, a fixed barrel weapon prevents the replacement of a barrel that heats up which brings among other inconveniences, a loss of accuracy and operating problems both related to the expansion of the “tube”. For the Utlimax 100, the replacement of the barrel due to overheating (and therefore in a context of intensive use) is recommended every 500 shots. Also, the barrel replacement capabilities allow the use of a lighter barrel, and thus building a lighter weapon.

The consistent feeding choice with respect to these support firing claims would appear to be a belt feeding, which allows a larger capacity for a more favorable weight and bulk than the transport of ammunition in magazines. However, this type of feeding has several pitfalls and in particular:

- It considerably complicates the weapon by the addition of a feeding device (belt traction, feeding tray …). This also results in an increase in the cost of production, an increase in the weight of the weapon and a loss in reliability.

- It complicates the operation of the weapon. Thus, even for a “light” belt fed weapon, it is better to be assisted by a comrade for the reloading phases.

- It makes the weapon more vulnerable to the surrounding foreign bodies. Belt feeding produces a “conveyor belt” from outside the weapon on which any kind of dirt can be found.

- Belt feeding is not shared by the other soldiers’ weapons. Therefore, if the feeding is done only in this way, it requires an additional supply chain. Obviously, it is possible to implement an auxiliary feeding device as on the Minimi, but this still adds weight and production cost to the weapon.

Thus, the use of the magazine, clearly makes this weapon an “individual” weapon, which means that its shooter is able to use it optimally without help. This is also an argument put forward in the manufacturer’s documentation. The relative loss of fire volume capacity allowed by a belt feeding was compensated (as often in these cases) by the adoption of 50 and 100 rounds drum magazines. The desire to make a “simple” and “reliable” drum magazine probably dictated the choice to reduce as much as possible the length of the magazine well and, consequently, the method of locking the magazine on the weapon. For the record, the same choice was made by the Soviets with the evolution of the PPD-34 to the PPD-34/38, where the “neck” of the magazine disappears. A third method of locking for the magazine of the brand: that of the AR-15 used for the SR-88a and the late SAR-80 (rectangular opening on the left flank), that of the early SAR-80 (linear opening on the right flank, which looks like a lot to an AR-18 pattern) and two perforations on the top of the left flank: that of the Ultimax. All the weapons in 5.56 of the brand therefore share the same 20 and 30 rounds magazines. However, drum magazines cannot adapt to the brand’s assault rifles which have a “long” magazine well. It is also noted that the guidance of the 20 and 30-rounds magazines is carried out on the rear rib of the magazine, which contains the extension of the follower which usually controls the bolt stop. Here, there is no bolt stop!

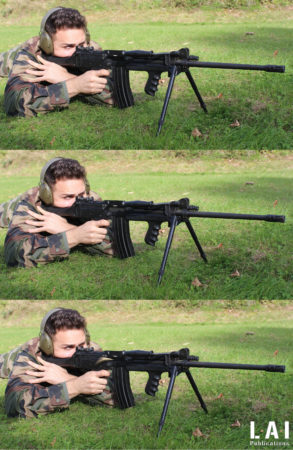

The weapon fits well into the assault organization because it is of a reasonable weight and individual implementation and it is compatible with the notions of maneuverability and urgency of implementation implied by an assault. The front grip and the removable bipod testify to this desire for integration. The handle combined with the reasonable weight – especially if we take into account the possibility of removing the bipod in a few seconds and being equipped with a short barrel – really allows to shoot while moving. The removal of the stock makes the weapon compatible with an evolution in a confined environment, which few LMG allows. To summarize with humor: with the Ultimax 100, you don’t need to be Arnold Schwarzenegger to engage in an assault all guns ablaze with a “LMG from the hip”! But beyond the humor, anyone who ever tried to shoot in motion with a more “conventional” LMG knows that this operation is not simple, mainly because of the weight (and its distribution) and the size of such a tool.

At the shooting range

The result is stunning: at the time of shooting, in a prone position, there is no recoil. The thing is edifying when filming the shooting sequence, especially in slow motion (a short video is available at the end of the article). Burst shooting in a standing position from the shoulder or the hip is superior to what is achieved with most assault rifles. The low rate of fire easily allows the production of single shot despite the absence of a selector. Let’s be clear, the firing of this weapon is very convincing, including on a comparative shot with the Minimi 5.56 with a high rate of fire (around 1200 rpm) and which produces a greater dispersion. It would seem that this problem has been mitigated on the last generations of the FN weapon by the adoption of a more efficient buffer. No LMG tested to date by us has proven to be as well balanced in firing as the Ultimax 100. The recoil being literally negligible, there is no climbing and very little dispersion on the burst. The burst shots at 600 meters carried out on reactive targets are… once again simply stunning! The real difficulty is (as always in this exercise) to discern the targets more than to reach them in short bursts. On “long-range” shots, the weapon would largely deserve the mount of an adapted optical sight to further increase operational capabilities, but this would not in any case make it possible to fill the gaps of the 5.56 at such distances in terms of terminal ballistics.

Disassembling and maintenance

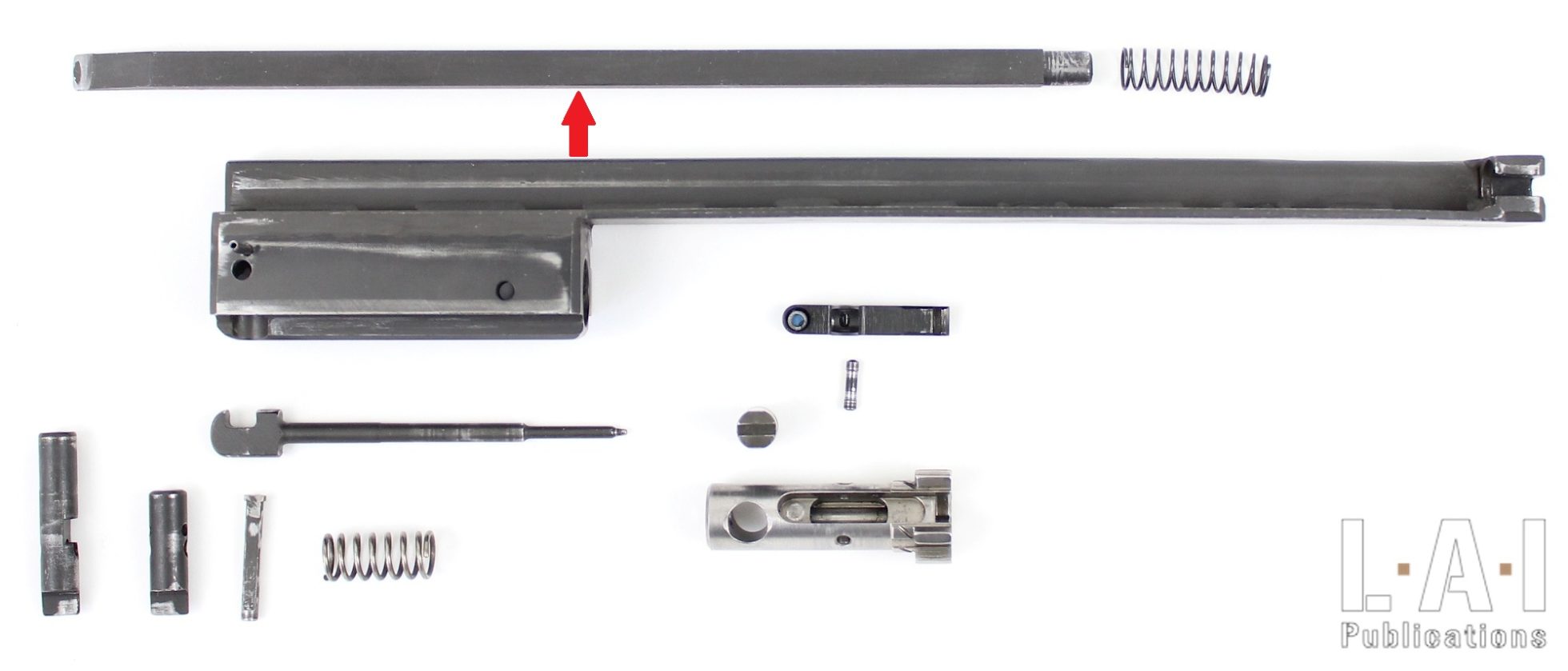

Disassembling is easy. The stock can be removed after the removal of two captive pins. It is then necessary to compress the extension of the recoil spring assembly forward in order to lower the closing plate of the frame. The maneuver of the recoil spring assembly is done through a cursor that protrudes on the right side of the weapon. The bolt carrier group can then be removed by the back of the frame. The disassembly of the bolt carrier group is done in a very “conventional” way: the retention pin of the striker is removed, then the removal of the striker from the rear of the bolt carrier releases the release cam. Once the cam is removed, the bolt exits forward. One can then take the extractor out as on an AR-15: we slightly compress the back part of the extractor and remove its pin. The removal of the recoil spring assembly is done simply: the guiding rod is compressed forward and it is taken out by sliding it to the right.

The removal of the barrel is carried out as indicated: one presses the control located at the front of the front grip, have it make 1/8th turn on the right, then extract it forward. The gas piston is disassembled by removing a captive pin located at the back of the gas block. It releases the piston retention ring, allowing the extraction of the piston and its spring. The cleaning can be completed by removing the nozzle: the regulator knob is aligned with the disassembly groove and the knob is extracted forward. The nozzle can then be driven backwards through a gas block.

The bipod is removed in a similar way to the barrel: one presses the control placed on the front of the front grip and the bipod is rotated on its axis to unlock it. It can then be taken out forward.

This disassembly is sufficient for the routine maintenance of the weapon. Additional disassembling is only to be considered in the workshop: the reassembly of the firing system is, due to its accessibility by the interior of the receiver, not easy to carry out in the field…

The accessibility for cleaning is very good for the gas block, but a little less for the frame. However, the gaseous contamination is very well limited by the design of the weapon and in particular by two large vents located on the back the gas block. Located at the rear of the piston stroke, they allow efficient venting of gases just after pulsing the bolt carrier group (Pic. 25).

Conclusion

The Ultimax 100 is a weapon with no real equivalent on the current market. These impressive shooting performances should not make us forget that this is not the only evaluation criterion for a weapon of war. Reliability, costs, durability (in terms of depreciation of the investment) are also preponderant criteria that it are difficult to evaluate without batteries of very expensive tests and not very accessible to the simple authors that we are. Excluded in 2010 from the USMC tender in favor of the M27 Infantry Automatic Rifle, a variant of the HK-416 halfway between a “Squad Automatic Weapon” and a “Designated Marksman Rifle“, the Ultimax 100 remains a very interesting weapon by the technical choices that constitute it. The choice of the USMC, for its part, testifies of a real reflection around the use of this type of weapon in combat.

Arnaud Lamothe

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!