Like the .45 ACP Colt M1911, the 9×19 Luger P.08, the TT 33 is one of those weapons that have made history. Forever associated with both the USSR and WWII, it is in many countries where the acquisition of handgun is possible, a safe purchase, the weapon being reliable, “powerful”, and often inexpensive. Sometimes considered wrongly and with disdain as “primitive”, it constitutes for its time, a rational and effective tool: a good weapon of war.

The 7.62×25 ammunition

Among the differences between the emblematic Soviet semi-automatic pistol of the Great Patriotic War and the other two weapons mentioned in the introduction, we can distinguish that this one came into being much later than the other two and that it does not use a locally designed ammunition, but an ammunition of foreign origin: the 7.63 Mauser (Pic.05). Imperial Russia had purchased a considerable number of 7.63 Mauser C96 from the German cousin (Tsar Nicholas II and Kaiser Wilhelm II are indeed cousins!). Thus, when the October Revolution broke out, among the large number of handguns of foreign origin that rubbed shoulders with the Nagant 1895, a substantial number of C96s were used by all belligerents during the civil war that followed for nearly 6 years. In the aftermath of the revolution, the 7.63 Mauser was familiar to all. There is no doubt that the caliber was valued both for its accuracy and penetration, this criterion being an important point of evaluation of a service ammunition.

It is therefore not surprising that prior to the creation of a pistol for the fledgling Red Army, this ammunition was chosen and “Sovietized” in the late 1920s. This sovietization consisted mainly in adapting the dimensions and tolerances to be able to standardize the manufacture of the barrels. Thus, the bore of the 7.62×25 and 7.62×54 R barrels would be identical (just like the 7.62×39 when it was adopted). From then on, the production and control tools are the same: a most rational production simplification. The CIP data for each caliber (7.63 Mauser and 7.62×25 Tokarev) gives an idea of the changes made. Let us not forget here that the CIP is a normative system dedicated to weapons and ammunition intended for the civilian market… and that army (or administrative!) materials are not under any obligation to submit to it! In addition to the dimension differences, it is important here to highlight that there can be considerable pressure differences depending on the origin of the ammunition… and the employment for which they were intended. No, it is not wise to fire ammunition intended to be fired in WWII SMGs in an antique C96! It is unlikely that the weapon will “explode” (objectively, there is no real reason), but its wear will be greatly increased.

Its adoption name would be “7,62-мм пистолетными патронами”, or “7.62 pistol cartridge” (Pic.06). We will call it 7.62×25: this distinguishes it from the plethoric panel of existing 7.62s …

The TT 30 and TT 33

Quite commonly in the Soviet Union, weapons designers were put in competition for the adoption of a semi-automatic pistol of 7.62×25 caliber. On the ranks, Sergey Aleksandrovich Korovin, Sergey Aleksandrovich Prilutsky and Fedor Vasilievich Tokarev.

The two comrades Sergey Aleksandrovich (yes, they have the same first names!) had already competed for the adoption of a pistol in 6.35 Browning. The model of Korovin, which became the Tula Korovin 1926 (presented here by Luc Guillou), was then selected. S.A. Prilutsky, whose name is unfamiliar to the general public, was not at his first attempt: he had made a semi-automatic pistol (the M1914) which was promised a bright future in Imperial Russia but whose destiny was brutally interrupted by WWI and then by the October Revolution.

Fedor V. Tokarev (1871-1968) had also begun his career in the service of the Tsar of All Russia, as a gunsmith of the 12th Cossack Regiment in 1891. In 1907, he created his first semi-automatic rifle with a removable magazine by converting an 1891 Mosin-Nagant rifle. The weapon was perfected between 1908 and 1914 at the Sestroretsk arsenal, but here again, WWI and the October Revolution put an end to his work. However, his creativity would have left its mark on the spirits, and in the aftermath of the Russian Civil War, it would be widely used: in 1925, he would develop the “Maxim-Tokarev” machine gun and after the end of Fedorov’s work on his automatic rifle, he would create the first Soviet “submachine gunSubMachine Gun More” in 1927 (some details of which are developed in the article on the PPSh-41). After his work on semi-automatic pistols, Tokarev would return to his first subject: the semi-automatic rifle with the SVT-38 and SVT-40… But that’s another story! Finally, Comrade Tokarev, Hero of Socialist Labour, was even the designer of a panoramic camera in the 1950s: the “Fotoapparat Tokarev“!

The designers presented their models in 1929, S.A. Korovin and S.A. Prilutsky having adapted their previous work to the 7.62×25 as requested. For his part, F.V. Tokarev would propose… a machine pistol! Equipped with a heavy blowback bolt, a firing selector, a disproportionately long barrel … The weapon did not really meet the competition criteria. He therefore presented a semi-automatic pistol with locked bolt of more reasonable size: this prototype, after some modifications, would become the TT 30. From June 25th to July 13th, 1930, the weapons would be tested and compared to foreign productions… as usual! Tokarev’s weapon turned out to be the most compliant with the requirements of a service weapon. If it was not the most accurate (it was Korovin’s weapon), this weapon was the most compact and reliable. Prilutsky’s weapon was distinguished by its ease of disassembly. Considering that the Tokarev weapon met 75% of the requirements, it was selected with the following modification requests:

- Accuracy needed to be improved.

- Sights needed to be improved.

- Safety needed to be improved (the concept of safety probably needs to be taken into account in the overall aspect of the safeguards offered by the weapon).

- The trigger release had to be softened.

- All defects found during the tests must be corrected (here is a very generic sentence of administrative decisions…).

If we take a closer look, 3 out of 5 requirements (1, 2 and 4) are intended to improve the hit probability! There is also a factor that would often be taken into account among the Soviets: the trigger release. Much more than the intrinsic accuracy of the weapon, its improvement considerably increases the hit probability of a large population and ultimately, not fully trained in shooting.

On January 7th, 1931, a test of the new version was carried out in front of high-ranking officers. As it proved convincing, on February 12th, 1931, a request was made to order a first batch of weapons and on February 13th, 1,000 weapons were ordered. The weapon would be officially designated “7.62mm Pistolet obr. 1930” but was also called “TT” for “Tula Tokarev”, named after the designer and the city located 200 km south of Moscow and hosting the production plant of the weapon (Pics.07 to 09). A number of minor modifications would be made at the beginning of production, the weapon would become the Tula Tokarev 1930/33 and then simply the Tula Tokarev 1933 or TT 33.

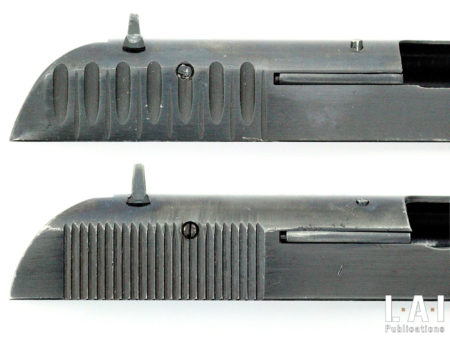

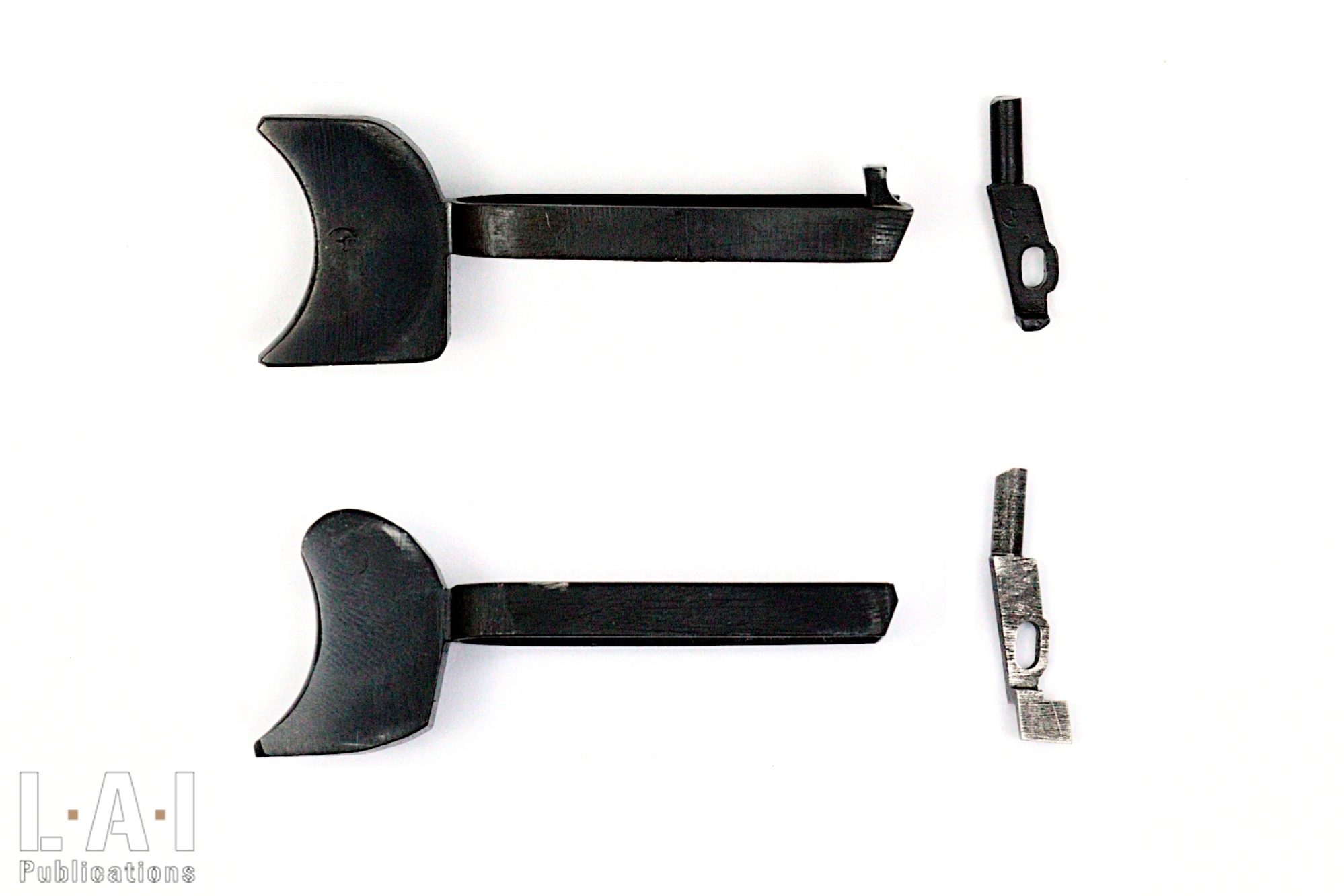

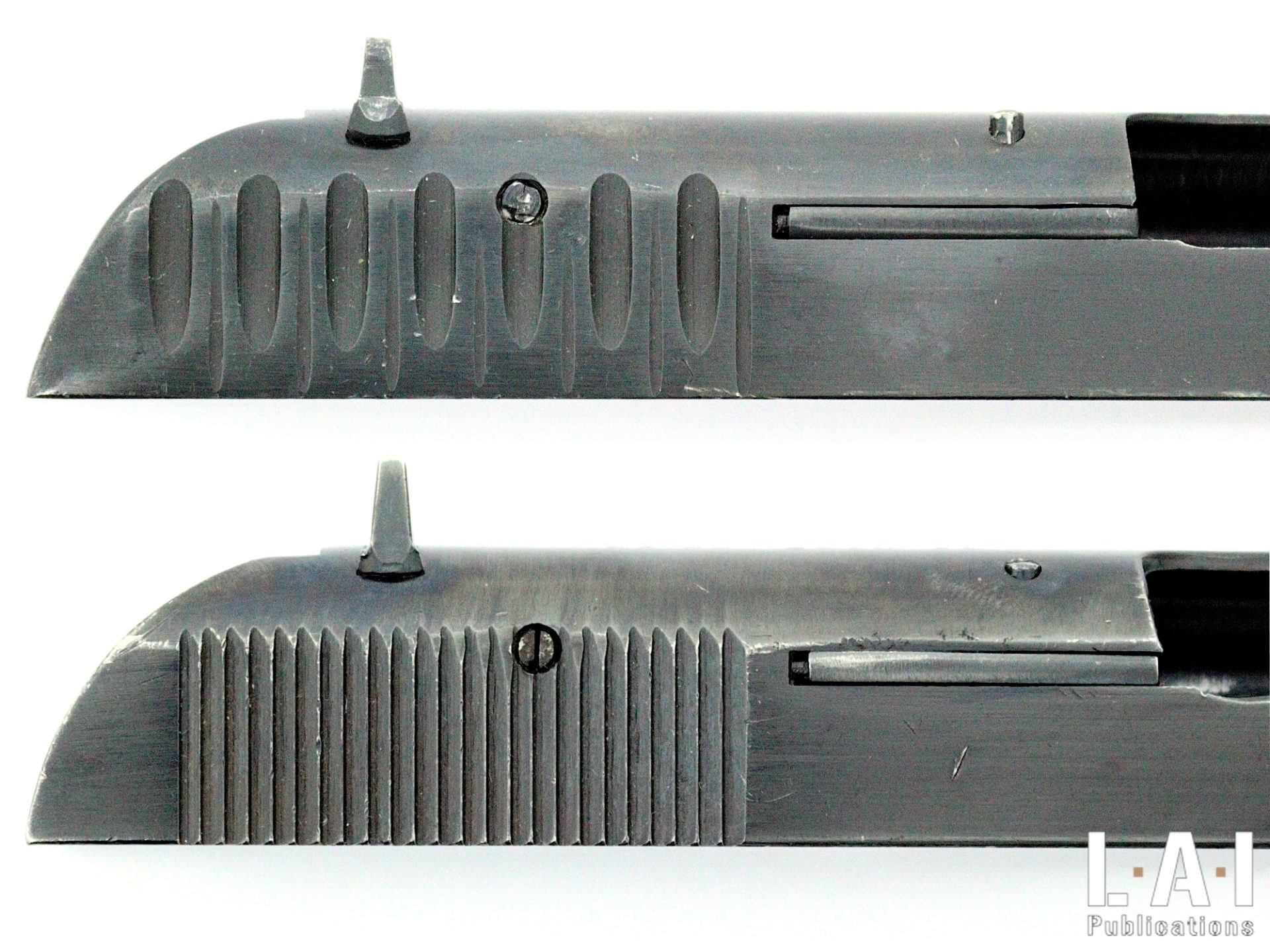

The most notable change is the implementation of the trigger in the frame. Originally, the back of the frame had an opening which allowed, after removal of a backstrap, the removal of the trigger spring and the trigger itself, not without having first disassembled the magazine catch! On the TT 33, a judicious redesign of the trigger, the disconnector and the frame allow the disassembling of the trigger and its spring by simple removal of the grips (detailed below) (Pic.10 to 13). Of course, the collector keen on TT 30 is always on the lookout for the variant where the barrel lugs are not made by lathing the barrel completely: but let’s be clear, this is only a “minor” simplification of production from the engineering point of view! Similarly, the weapon would experience variations in production, depending on the circumstances (as for the grips – Pic.14) but also, a modification of the gripping streaks of the slide from 1947 (Pic.15).

A “simple” pistol

The Tokarev pistol is characterized above all by its simplicity: no frills, a minimum number of parts and a minimum of functionality. The weapon, which is in single action, has as sole safety, a half-cocked notch which, in addition to neutralizing the action of the hammer, immobilizes the slide. The TT 33 has 47 constituent parts (at an industrial level) constituting 35 removable elements which you can disassemble with only a hammer and a drift-punch. No screws. This is not really a tour de force: at the beginning of the century, many automatic pistols and revolvers could be largely disassembled simply with only a couple of tools. But here already, we can feel a very Soviet obsession: the weapon is actually simple to produce regarding the era. Because yes, often, these “simple” weapons had only the appearance of simplicity and proved very expensive to produce. When disassembling, the weapon is not that simpler than a 1911 or a P.08 (of course, the removing of the firing mechanism in a unique block is a plus): but when manufacturing, it is another matter… the 1911 obviously holding the comparison better than the P.08. The P.08 is a masterpiece of gunsmithing… But as often with the Germans before the end of the 1930’s, an industrial madness…

At the mechanical level, the weapon obviously finds inspiration abroad as well as indigenous innovations: the thing would be recurrent with the Soviets. It is not a question here of well-placed national pride, but of producing a tool that fits a need. This trial is often badly conducted by critics of Soviet weapons (often by ideology more than by mechanical analysis…). They think they are pointing at little creativity, but they do not understand that:

- All inventors have drawn on the experience of their predecessors and the world around them all over the world. Faced with a need, an inventor who does not look at what is being done elsewhere shows a rare stupidity…

- The absolute desire to move away from a system that works, to re-invent a system with a similar goal, but potentially less reliable, more complex, more expensive can only raise two things: misplaced pride (therefore, stupidity) and a greed linked to a patent exploitation. Make your choice!

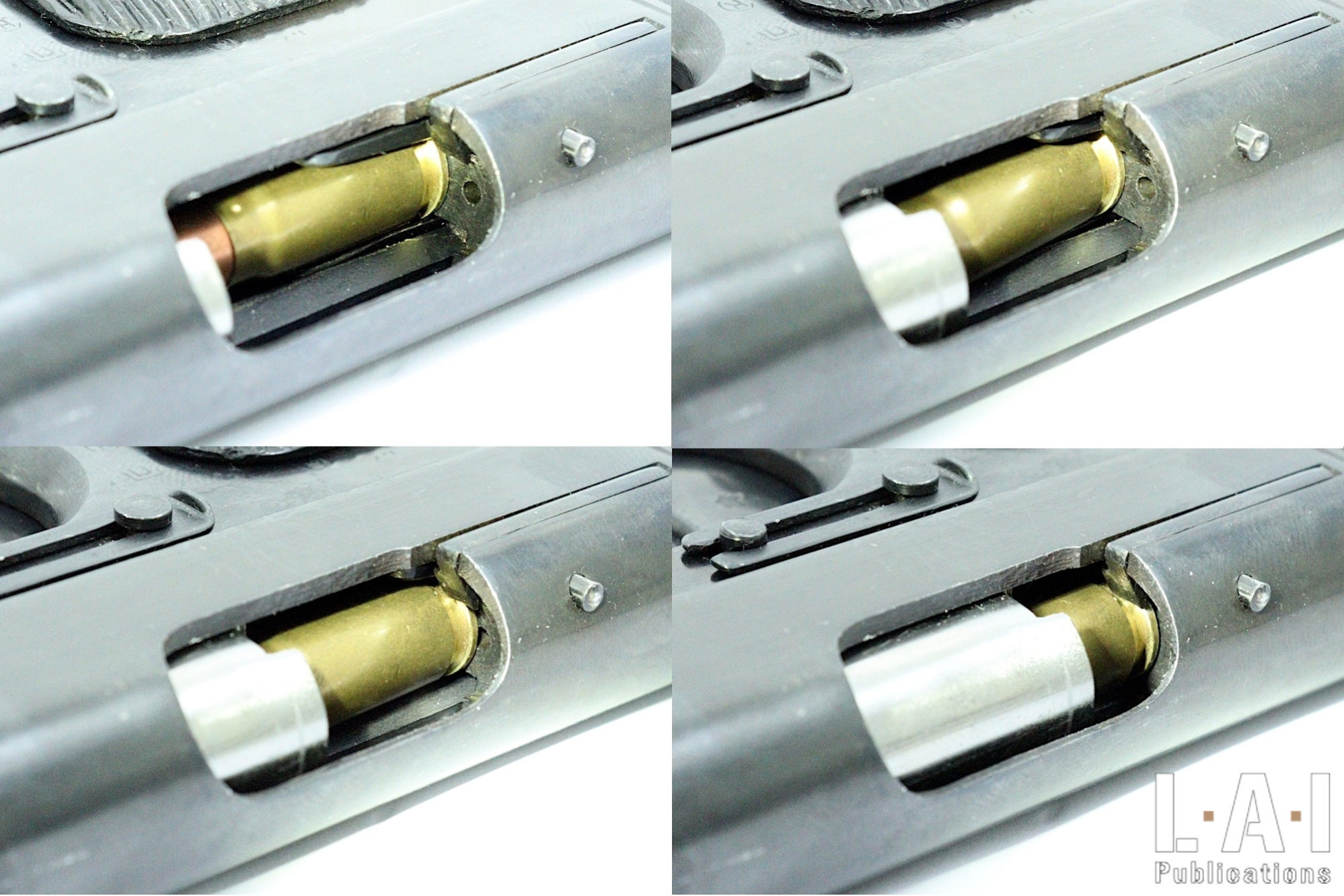

But back to our subject. The weapon operates from a locked bolt based on the principle of the barrel short recoil. The locking is realized, in the manner of the system invented by John Mose Browning, by lowering the rear part of the barrel (Pic.16). Caused by a connecting rod binding the frame (via the axis of the slide stop) to the barrel, the lowering causes the separation of the lugs (on the barrel) from their recesses (inside the slide) clearance, and therefore the unlocking. And there is a total of… 3 lugs! Yes, we must not forget the massive one constituted by the rear part of the barrel.

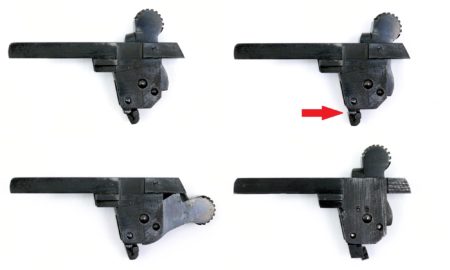

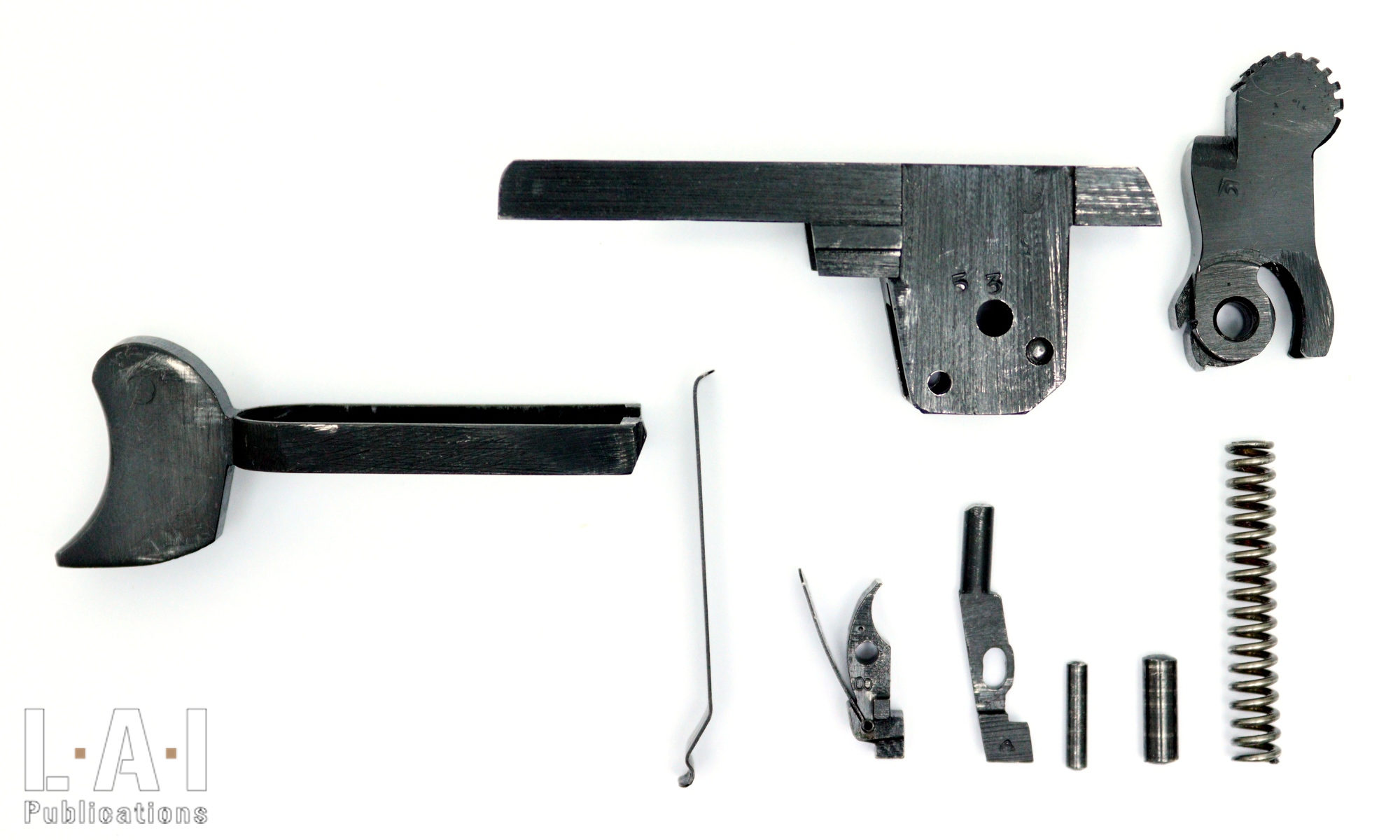

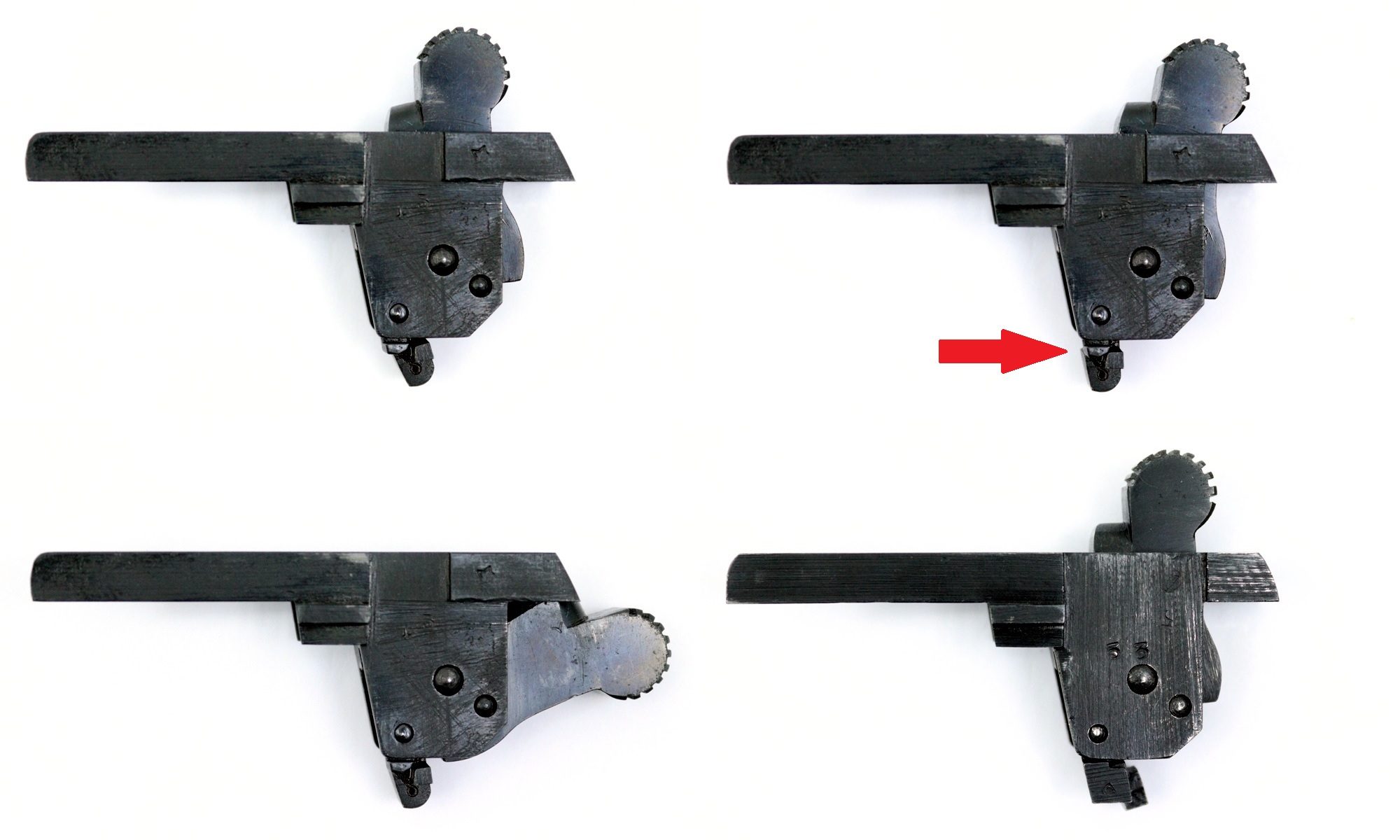

The firing system is a model of simplicity for the time. On the hammer block itself: 8 constituent parts (9 at an industrial level), axis and spring included. By adding the trigger and its return spring, we are at 10 (12 at an industrial level – Pic.17). In addition to the fact that the firing mechanism is removable without tools when disassembling the weapon, it has the particularity of having the hammer spring cleverly positioned … in the crest of the hammer! Thus, this spring does not have any problem of size and the firing mechanism is of a rare compactness. The disconnector, intended to interrupt the connection between the trigger (by lowering it) and the sear during the rear movement of the slide, is used in a second role. When the hammer is positioned on its half-cocked notch, an extension of the sear is lodged under the lower end of the disconnector, preventing its lowering (Pics.18 and 19). Thus, the disconnector locks the slide. The thing seems problematic for handling (you have to think about removing the half-cocked notch to handle the slide): in reality, it allows you to put the weapon in the holster without fear of operating the slide by friction. Similarly, at the time, it was not inconceivable to carry the weapon, ammunition chambered, hammer half-cocked: the disposition is no less safe than to carry a Colt 1911 or a P.08 chambered, armed and safety engaged! It may even be safer, as the hammer is not cocked…

The firing pin is of the “hit and press” type, but is subjected to a return spring, probably for safety reasons. (Those interested in more details on the difference “hit and throw” and “hit and press” can refer to Chapter 6 of the Small Guide for Firearms).

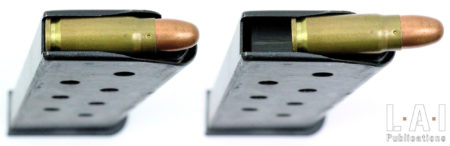

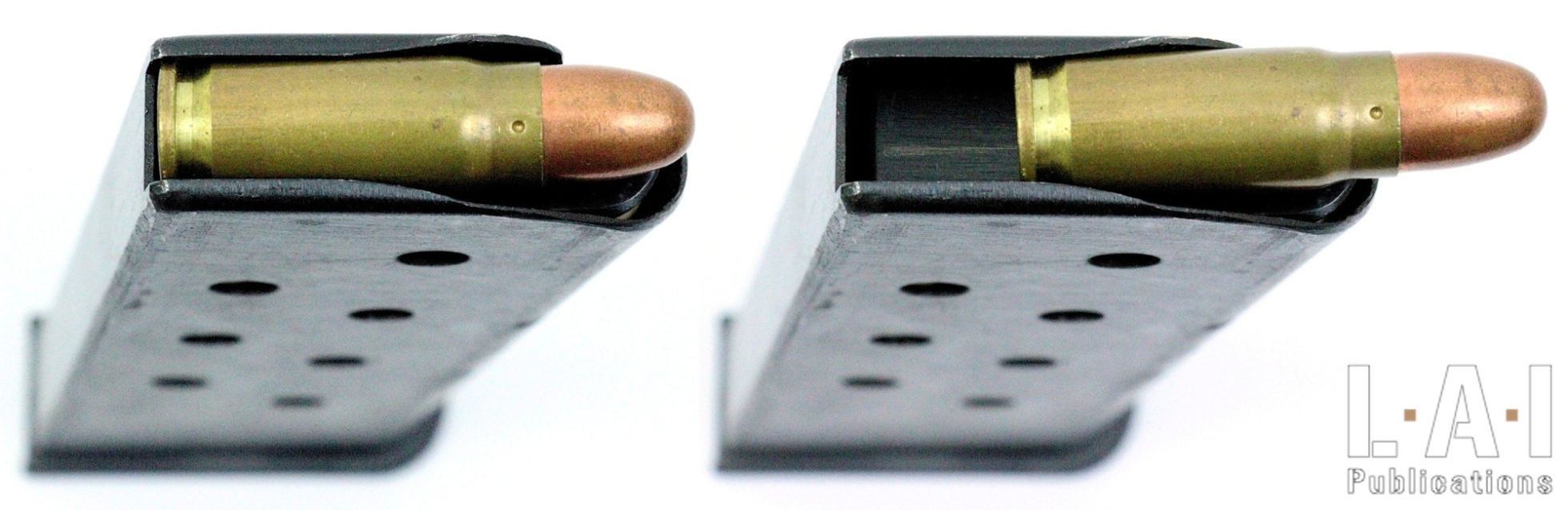

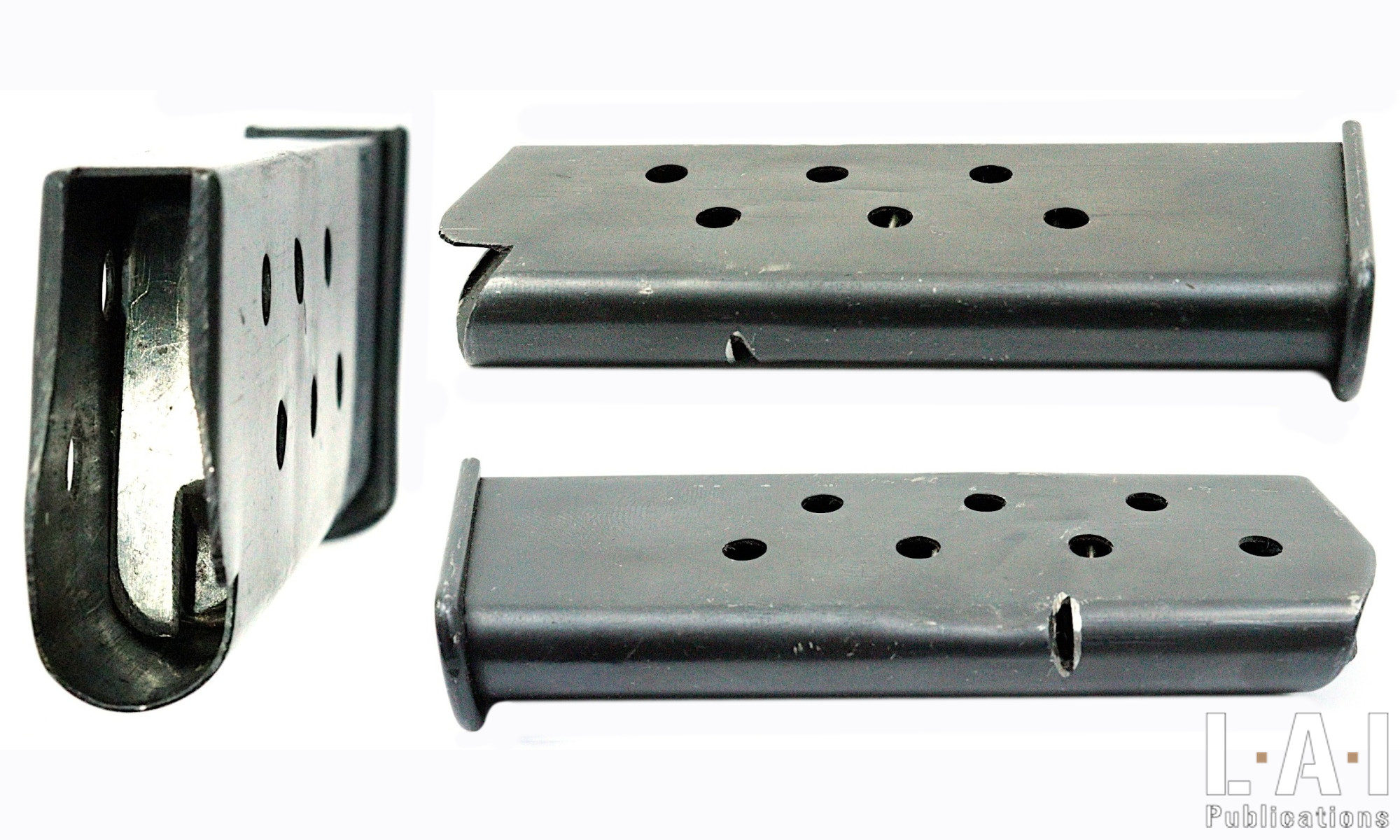

The weapon is fed by a single-stack magazine of 8 rounds (Pic.20). In order to make the weapon more reliable, the feeding is “controlled” (Chapter 6 of the… ok, you get it!). Thus, when an ammunition leaves the lips of the magazine, it is taken into account for a short time by the front part of the firing mechanism body which has lips. Leaving the latter, while the nose of the ammunition is already in the barrel, the ammunition head is taken into account by the large extractor designed for this purpose (Pic.21). This specificity of having part of the ammunition guidance be provided by the frame (here, by the firing mechanism body which is attached to the frame at the time of firing) is already present on the Colt 1900. Its purpose is to minimize (not eliminate) the function of the magazine as a guide… but does not in any case protect the weapon in case of its deterioration … especially since the reliability of a magazine is not only related to its lips (Pics.22 and 23).

The extractor / ejector set (fixed on the firing mechanism body) is a great classic, except that the extractor spring surprises by its small size (Pics.24 and 25)! However, it does not seem to be a source of problem: and for good reason, the positioning of the axis of the ejector, far forward, gives it a considerable mechanical advantage by leverage! Finally, as mentioned above, the extractor takes into account the ammunition by sliding at the exit of the magazine and not by “jumping” over the base of the ammunition. Thus, it is of a very great rigidity without it being anything other than beneficial to the proper functioning of the weapon.

The weapon is equipped with a slide stop automatically controlled at the end of the magazine, which also acts as a disassembly key. Once again, the Soviet habit of the multiple function for the same part struck again: the retaining spring of the slide stop also acts as a return spring for the same part (Pic.26).

And that’s all there is to it: the weapon is simple!

Shooting

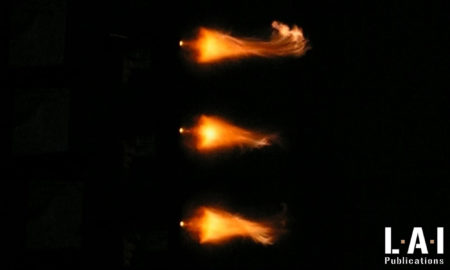

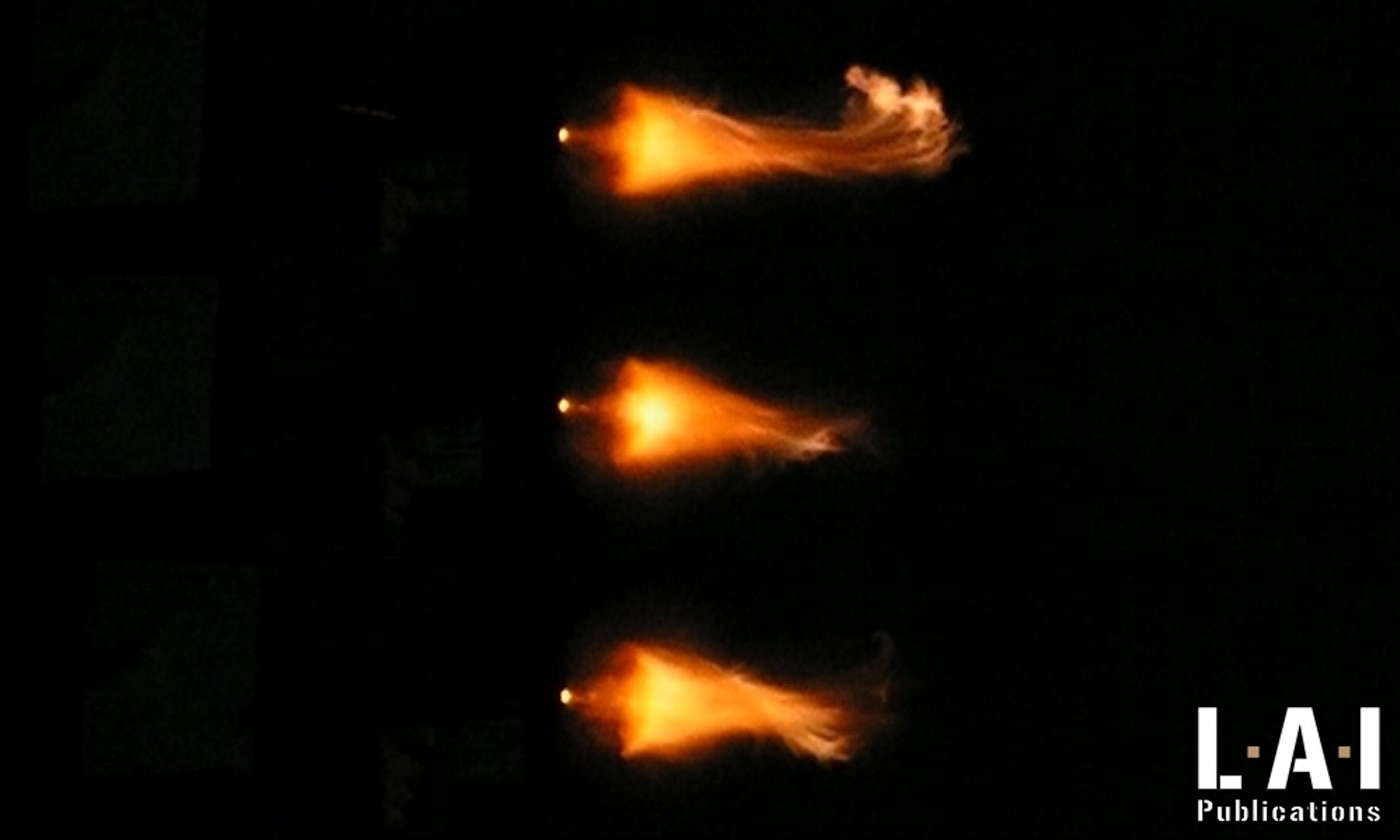

The Tokarev was my first center-fire pistol. The model that Gilles SIGRO had offered me (for service rendered!) is a Hungarian production, FEG M48 from 1952. Soon after, a 1938 P.08 S/42 (Mauser) joined my collection. So, I fired both weapons a lot during the same period. Let’s be clear, the P.08 is nicer and more accurate than a Tokarev, but much less reliable. The TT 33 has a particular grip: the handle, small size, at a very right angle… is very like a… Broom handle! Curious, isn’t it? If the trigger release, direct, is not bad, the recoil, with a service or manufactured ammunition is at least dry, the sound rather violent and depending on the ammunition … the flash impressive (Pic.27). On some shooting ranges, the Tokarev even ostensibly disturbed my neighbors who were shooting in a more … academic way. The sights (the rear sight is U-shaped), well drawn, allow a precise aiming more than instinctive (Pic.28). The results on the target are correct, but clearly not exceptional in our hands. We made much better use of our Luger, with which at the best of our form, we consistently hit the 9 of the 50 Pistol Target at 25 m and shooting one-handed! At the same time, with our M48, consistently hitting the bullseye was already a considerable satisfaction!

Is this prohibitive for a weapon of war? No, clearly not. Since that time, our shooting practice has evolved and has taken “distance”. Thus, we took out different TT 33 off the 25 m to bring them to 100 m … and even further! The target has also changed: a lover of diversity, we also work with other targets, including the French military SC-2 (kneeling figure). And here, the observation is simple: to score at 100 m on an SC-2 with a TT 33 is quite achievable… The weapon is therefore accurate enough for general service use! Asking this type of weapon to make 10s and even 9s in a target at 25 m is nonsense.

In terms of reliability, nothing to complain about: on several Tokarev fired for nearly 20 years now, only a handful (close to no) jamming and only one broken part: the disconnector of the FEG M48 left me a few years ago. The weapon has probably already shot several thousand rounds… and maybe a lot of manipulation, some of which may even be considered shady…

Disassembling and maintenance

The TT 33 is a pleasure to disassemble. Not only for the summary disassembly, but also for the advanced disassembly of the firing mechanism! The video shall convince you! Well, the realization of some sequences required several takes, but only in order to be more presentable: away from the camera, we do not care to place these fingers so as to make the action visible while keeping the focus! And let’s recall here: I am neither Ernest Hemingway, nor Orson Welles! Just a technician, who shares his passion.

For field disassembling:

- Remove the magazine… and check that there is no ammunition left, neither in the magazine(s), nor in the weapon, nor even on the working area.

- By hand or with the help of a suitable tool (a spent case can do the trick… On the Soviet manual, the manipulation is carried out with the back of the magazine!), disengage the spring of the slide stop.

- The slide stop thus released, a very slight recoil of the slide (to relieve it) makes it possible to remove it very simply.

- Gently move the slide / barrel assembly forward, while encompassing with one hand the recoil spring as it appears. Indeed, as the spring comes out of the weapon, on some weapons, the guide rod tends to slide on the foot of the barrel and jump out of the weapon … take care!

- When the slide / barrel assembly is separated from the frame, the recoil spring assembly is removed by disengaging the spring guide from the barrel foot and then extracting from the front of the slide.

- Rotate the bushing 180° and remove it from the slide.

- Extract the barrel from the front of the slide.

- Extract the firing mechanism from the frame simply by pulling it out.

Obviously, in all cases to this field disassembly, the disassembly of the magazine is added:

- The locking plate of the magazine is pushed inside using a suitable tool (screwdriver blade).

- When the locking plate is pushed, the magazine floor plate is slide forward. As soon as possible, the screwdriver blade is removed.

- By opposing one’s thumb to the outlet of the magazine, the floor plate is removed.

- Taking care in relieving the magazine spring, the locking plate, the magazine spring and the follower are removed. Be careful to remember the direction of mounting the magazine spring!

We can add the disassembly of the firing mechanism (included in the Soviet instruction manual!):

- If needed, release the hammer by pushing the sear. If the hammer is half-cocked, it’s also needed to pull back the hammer slightly.

- Without passing the half-cocked notch, slightly compress the hammer and using a suitable drift punch, remove (normally without knocking) the sear / disconnector axis.

- Remove the sear and disconnector down.

- Remove the axis of the hammer.

- The hammer and its spring can be extracted from the top of the housing.

Disassembling the grips is very simple:

- Using a suitable tool (if possible, synthetic or even wood), the locking blade of the left grip is tilted towards the back of the weapon. This operation is carried out through the inlet of the magazine well.

- Thus unlocked, the plate can be removed and gives access to the locking blade of the right grip.

- Using the same tool, tilt the locking blade of the right insert… and remove it!

On the TT 33, disassembling the trigger and its spring is therefore very simple:

- The trigger spring is compressed by hand, which allows to tilt downward the rear part of the trigger inside the frame.

- Pivoting around the magazine catch, the trigger is removed from the frame.

- Pivoting around its axis (normally non-removable), the trigger spring is removed.

For gourmands, we can add the disassembly of the firing pin. Without having to be systematic, it is not superfluous once in a while, just to remove impurities, but also sometimes piles of varnish and of course in order to apply lubricant. The procedure is as follows:

- We can identify the direction of disassembly of the firing pin: it is a pin split on one side and shouldered on the other. It is therefore necessary to locate the slit to get out the shouldered side.

- The drift punch is positioned on the split part and knocks to extract the pin.

- When the pin is out and the drift punch occupies its place, position a finger on the back of the firing pin before removing the drift punch, so as not to eject the firing pin and its return spring.

- The firing pin and its spring thus removed, they can be separated by pulling the spring while giving a clockwise rotational movement.

For the hungriest ones, we can add the disassembly of the extractor. It also does not need to be systematic but is not useless from time to time. The procedure is as follows:

- Through the inside of the slide, with a suitable drift punch, the axis of the extractor is flushed.

- Once removed, the extractor can be removed from its housing.

- The extractor spring often remains in its housing: to extract it, one solution is to insert a needle.

For those close to starvation (of knowledge that is, right?), we can end up by disassembling the magazine hook. We feel this disassembly is the most superfluous, and even, counterproductive, because it can damage the retention of the magazine catch. Indeed, it does not allow in any case to access a space that would replace by its geometry cleaning or lubrication. Also, we only consider it in case of force majeure (oxidation, damage to one of the parts …) … or for the lucky owner of a 1930 frame pistol! Indeed, on such a frame, as already mentioned, it is needed to remove the magazine catch prior to the trigger disassembly. On both the 1930 and 1933, the procedure is as follows:

- Using a suitable drift punch, the right end (split, like the firing pin axis) of the magazine catch button is hit.

- The button and its spring come out from the left side.

- The magazine catch lock can be extracted from the right side.

And thus, the lucky owners of a TT 30 (or TT 30/33), can performed the trigger disassembly:

- Lower the handle backstrap lock.

- Remove the backstrap.

- Remove the trigger from the back of the frame.

The weapon is totally disassembled! (Pic.29 and 30)

The reassembly is done in reverse and presents little difficulty. However, we note:

- One needs to engage the spring of the sear in the groove of the firing mechanism body before repositioning its axis.

- Index the firing pin well before pushing its pin (the opening is positioned upwards).

- Properly position the extractor pin: on most of the 1933 the top of it is beveled in order to best fit the top of the slide.

The Tokarev is particularly easy to clean: as with the MAS 35S and the later MAC 50, the ability to remove the firing mechanism in a very simple way greatly facilitates operations. Particular attention should be paid to cleaning the barrel, as the majority of surplus ammunition employ corrosive mercury fulminate primer. We will therefore clean it abundantly… with soapy water. Given these small dimensions, you can do it in your sink while washing your dishes, it works very well: no excuse! In the end, it will be duly dried then lubricated, inside and out: remember there must be no oil in a barrel … but only at the time of firing! For storage, it’s needed and even necessary!

To conclude

A simple and effective tool, the TT-33 would not limit its career to the USSR and WWII. Produced by various member countries of the Warsaw Pact (Poland, Hungary, Romania), but also by “Brother” countries (China, North Korea, Yugoslavia/Serbia), it has been present since its creation on a major part of the world’s conflicts, as well as on civilian firing ranges and unfortunately within criminal organizations. The weapon has nothing more or less than a Glock for this: it is simply available and reliable. We have not presented here the productions outside the USSR of the weapon, and for good reason, these will be the subject of chapters to come!

Arnaud Lamothe

Thanks:

Gilles Sigro-Peyrousère (Atelier Saint-Étienne) for having offered me one day in 2004, my first Tokarev, a FEG M48… and thus passing on the Soviet weapons mania!

Source:

D.N. Bolotin, “Soviet Small-Arms and Ammunition”.

Soviet service manual (in Russian) (as visited on November 18th, 2022):