PPSh-41, Soviet’s first mass production weapon

The iconic Red Army submachine gunSubMachine Gun More was not simply a powerful tool massively available to the Soviet soldier, but it was also a first step in the area of small arms designed for mass production in the USSR. An important step in an economy that would be war-oriented, not for the few years that would follow the beginning of WWII, but in a global struggle that was to last for several decades.

Hesitations about the operational added value of the SMGSubMachine Gun More

In the aftermath of WWI and the October Revolution, the place of the submachine gunSubMachine Gun More was subjected to debate within the very young Red Army. Here, as in most other nations, the observation that the handgun provides nothing more than a personal defense capability and that the infantry rifle is not suitable for close combat was quickly established. However, the solution on how to equip the basic soldier is then not as simple as it seems. The infantry rifle (still almost exclusively a manual repeating rifle) still occupied a prime position in the equipment of the infantryman from all over the world. The ammunition of handguns was perceived by many as “too weak” for military use. Here as elsewhere, the supporters of this thesis saw the future of the submachine gunSubMachine Gun More as being limited to police missions.

In the USSR, the temptation of the intermediate cartridge was already present. If Fedorov’s weapons in 6.5×50 mm SR Arisaka had paved the way for reflection on caliber reduction, they are nonetheless rather light machineguns and not real assault rifles. The use of a “non-standard” ammunition (understand here, other than 7.62x54r, 7.62×38.5 Nagant or even 7.63 Mauser, the “usual” cartridges of the Red Army – Pic. 04) and an excessive complexity of the weapon would put an end to the development of this type of weapon in 1924.

As a paradox, it was the end of this development that triggered work on the first SMGSubMachine Gun More in the Soviet Union in 1925. Thus, the first locally designed SMGSubMachine Gun More tested that same year by the Soviets was the work of Fedor Tokarev. The Russian author D.N. Bolotin reports in this respect that F. Tokarev did not consider the design of a SMGSubMachine Gun More until Fedorov’s work was stopped: it seemed obvious to the designer of the TT-33 that the solution that would be chosen would necessary be the one explored by the venerable Fedorov, that is, a weapon filling the gap between the handgun and the infantry rifle! This first Tokarev’s SMGSubMachine Gun More, in caliber 7.62×38.5 Nagant, is more of an “automatic carbine” than a real SMGSubMachine Gun More. Note that the ammunition used for this weapon has a rounded and non-truncated front end to facilitate feeding in a magazine fed weapon (Pic. 05). Extensively studied (and compared to foreign weapons, especially German) by the Red Army, it would also be declined in 7.63 Mauser, judged by its power, more suitable for the military mission. This first weapon would be followed by a weapon proposed by V.A. Degtyarev (in 1929), S.A. Korovin (in 1930) both in 7.63 Mauser, soon named 7.62×25 Tokarev with the adoption of the TT-33.

Degtyarev’s weapon was very inspired by the production of his recently adopted DP LMG. There are similarities in construction and even a flat circular magazine over which the aim is taken! From a concept closer to a SMGSubMachine Gun More than Tokarev’s weapon, it operates from a mechanical advantaged blowback whose detail is not known to us. Korovin’s weapon, even more “common”, operates from a straight blowback bolt, but has the originality (for a SMGSubMachine Gun More of this era) to have a firing mechanism with a hammer. The evaluation of the 4 weapons (those from Tokarev being evaluated in each caliber) was launched in 1930. No weapon giving total satisfaction, the designers were sent back to their workshops. On February 11th, 1931, 500 Tokarev’s SMGSubMachine Gun More in 7.62×38.5 caliber would still be ordered for troops trials. Of course, the ammunition would be considered not powerful enough for the intended use.

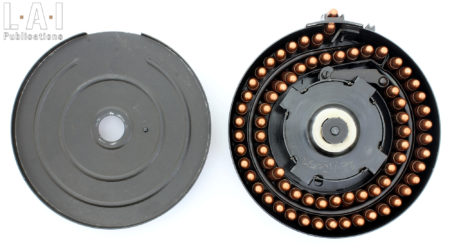

For his part, V.A. Degtyarev completely designed his weapon all over again, setting aside any reminiscence of the DP LMG. The result is a weapon with a more conventional design for a SMGSubMachine Gun More. It is finally this weapon that would be adopted by the Red Army under the name Pulmet Pistolet Degtyarev 1934 or PPD-34 (Submachine GunSubMachine Gun More Degtyarev 1934). The weapon did not give full satisfaction and was modified in 1938 to become the PPD-34/38. This weapon would use a 71-rounds drum magazine with a long extension, source of numerous stoppages. However, these weapons, which would not be produced in large numbers, would finally be withdrawn from service just before the Soviet-Finnish War (which Russians call “The Winter War”) depriving the Soviet Union of SMGSubMachine Gun More but also of the feedback of using such weapons on the front. The Finns, on the other hand, took excellent advantage of KP-31 Suomi SMGSubMachine Gun More: it is this observation that would promote the SMG’s return to the light in the Red Army. On February 15th, 1940 – a month before the end of the Winter War – a final version of Degtyarev’s weapon was adopted: the PPD-40 (Pic. 06). This one introduces the drum magazine without extension similar to that found on the PPSh-41. The weapon was massively produced over its short lifespan (81,118 copies in 1940 and 5868 in 1941): still presenting a number of problems, production was stopped during the year 1941.

Georgiy Semenovich Shpagin

Born in 1897, Georgiy Semenovich Shpagin worked in Kovrov where Fedorov and Degtyarev also had their workshops. He participated in the development of the DShK-38 heavy machine gun (Degtyareva Shpagina Krupnokaliberny) in 12.7×108 caliber, still widely used today.

G.S. Shpagin is presented by the Russian author D.N. Bolotin as a person particularly concerned with productivity issues and avant-garde in this domain. Mechanical simplicity seemed to be at the heart of his creativity… a trait finally very common among Soviet designers that is undoubtedly inspired by Soviet doctrine! The early 1940s marked a turning point in the use of folded sheet metal and electric welding. Thus, G.S. Shpagin would be the first in the USSR to use these new technologies for the manufacture of small arms.

The first version of Shpagin’s Pulmet Pistolet dates from 1940. It already has the attributes that would make the success of the weapon: obviously the massive use of the folded sheet and welding for the manufacture, but also the presence of a muzzle device combining muzzle-brake / climbing-compensator (which improves the grouping of the weapon in burst by 70% compared to the PPD-40 dixit Bolotin) and a simple implementation for the soldier.

That same year, Shpagin’s weapon would be confronted with the PPD-40 and a weapon designed by Boris Shpitalniy. The latter, without being devoid of quality, proved to be less in line with the expectations of a weapon of war (production cost, ease of use and maintenance, etc.). At the end of this competition, Shpagin’s weapon was adopted on December 21st, 1940, under the name Pulmet Pistolet Shpagin 1941 or PPSh-41… just 6 months before Operation Barbarossa. Its acronym – PPSh – is pronounced “Pepesha” in Russian, in a way very close to “Papasha”, a colloquial word meaning “Dad” in a rather positive way in the context. Curiously, the nickname seems to be more present in Western literature than the Russians’!

A revolutionary construction in the USSR

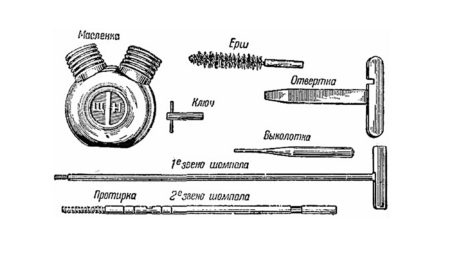

The manufacture of the weapon therefore uses folded sheet metal for the construction of most of its parts. The sheets used are appreciably different from those usually encountered: they are between 2.5 and 3.1 mm thick against, most often about 1 mm thick on other production, especially later. The PPSh-41 would also initiate a landmark construction – because it is used on the PPS-43 and even the AK as well – a U-shaped steel sheet receiver. This approach is very innovative compared to other SMGs: they often use cylindrical receiver (MP-18, 34, 38 and 40, KP-31, Beretta M38, STEN… and of course PPD-34/38). The cylindrical receiver makes it possible to make a good part of the parts from a lathe, a rational choice with the means of production of the time, because faster and simpler than multiple milling operations. For the modernization of the production of the MP-38, the Germans had adopted a sheet metal case, but still of cylindrical section. If some SMGs use parallelepiped receiver (Thompson whose front part of the bolt is cylindrical or MAS 1938 whose bolt is entirely … cylindrical!), they are rather rare, we humbly feel their approach/design derives from a productive immaturity … And what about Steyr-Solothurn SMGSubMachine Gun More? Well, that it is a magnificent weapon… but an industrial madness! On the PPSh-41, the bolt is of a parallelepipedal cross-section on its lower portion and slightly rounded on its upper part (Pic. 07). This choice was probably dictated by a simplicity in the mastery of the shaping of the sheet, where a parallelepiped shape is probably easier to obtain with suitable tolerances, than a receiver of cylindrical section. Moreover, after the war, several SMGs using sheet metal for their construction opted for a parallelepiped section receiver: MAT 1949, UZI, Madsen M-50, Vz-61, Ingram, etc.

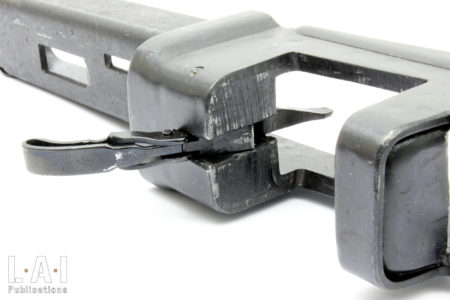

The frame of the weapon is made in two parts: a lower receiver and an upper receiver, both made of thick folded sheet metal. They are articulated around an axis at the front and locked by a hook actioned by a pusher at the back. The lower receiver accommodates the bolt, the firing system, the stock and the magazine well, whose specificities are very closely related to the PPD-40… and some part to KP-31! Let us pay credit where credit’s due! The upper receiver accommodates the barrel and sights. Its front part extends into a protective shroud (punched with many slots intend for cooling) and ends with a large muzzle device (Pics. 08 to 10). The latter, directing the gas upwards and on the sides, acts as a muzzle-brake and a climbing-compensator. The barrel, of a simple profile, is pushed and pinned into the upper receiver (Pic. 11).

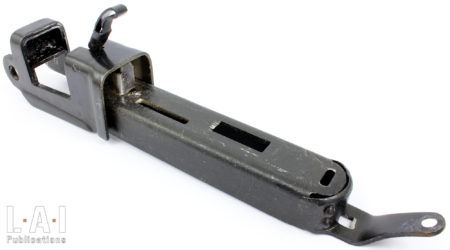

The lower receiver is particularly interesting: its complex shapes reflect a thoughtful design (Pic. 12). Concerning the bolt, the upper receiver is content to officiate as a “bolt cover”. The choice of a sheet of high thickness is probably related to the nature of the steel, of lower quality (some sign of wear testifies to this). What saves here “precious” material (quality steels are then prized for more “noble” manufactures than infantry armament) is paid for in terms of weight. Indeed, in our scale the PPSh-41 without magazine weights 3.875 kg … heavier than an AK-47 Type 3 with a solid stock, 3.8 kg without magazine… yes, one of two forged/machined receiver variants! It is necessary to be wary here of the values announced by certain sources… these are sometimes completely fanciful… Here, the weapons were weighed on the same scale: thus, even if this one is badly set, the result of the comparison remains valid…the PPSh-41 is heavier than the AK-47 type 3 with fixed stock.

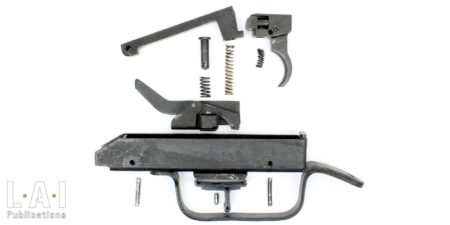

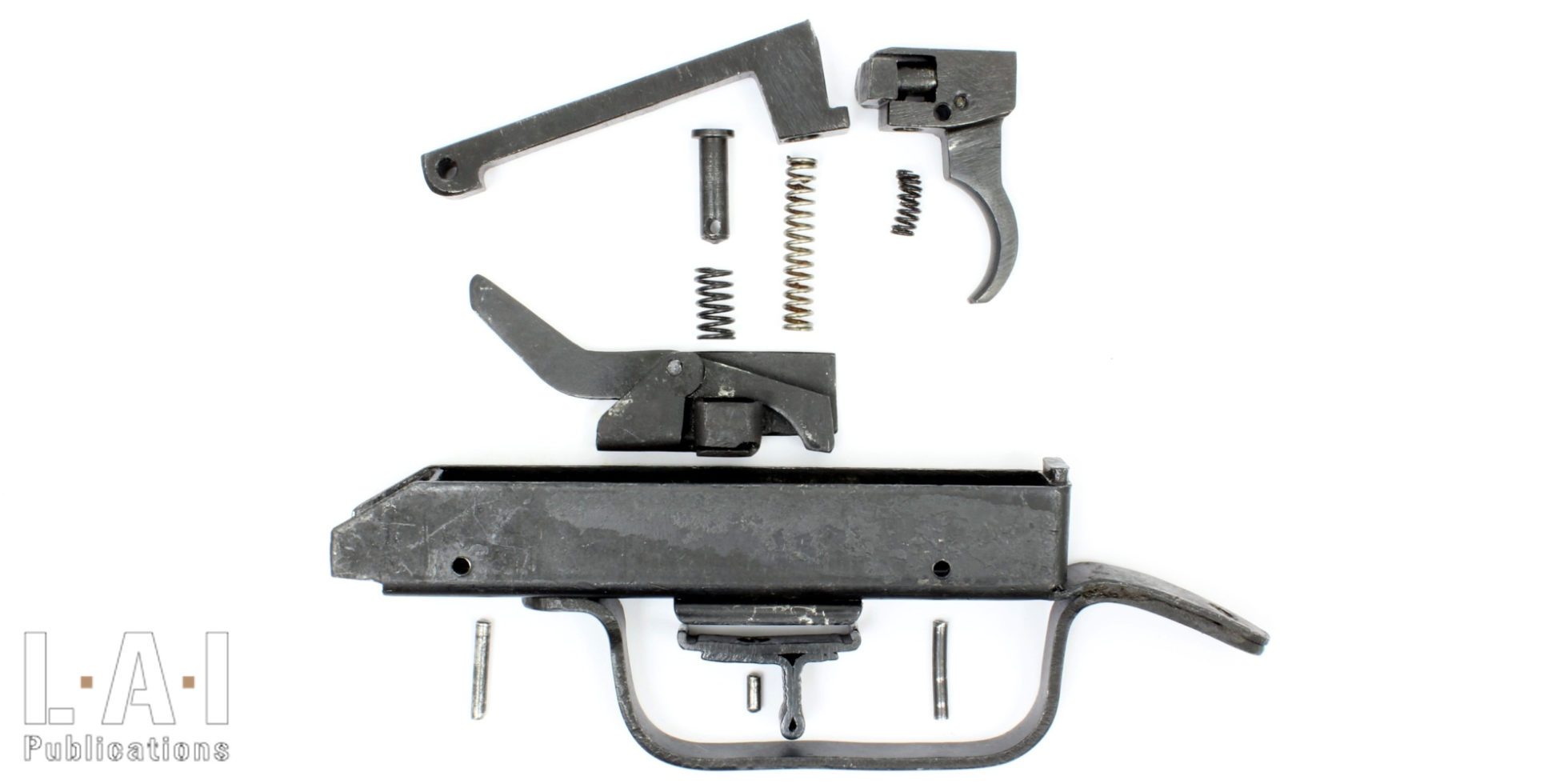

The firing mechanism box is also made of sheet metal (Pic. 13). Out of 17 constituent parts (somewhat abusively, we count here the box as a single part, but it is actually made of several metal sheet welded together), only 3 are machined: the trigger, the sear and the separator. These are parts subject to mechanical stress: impact, friction. This remains a performance, especially for a device that offers selective fire. Similarly, the lower receiver accommodates only two machined parts: the ejector (riveted) and the magazine catch (Pic. 14). The reason for this is the same, these are the parts subject to constraint.

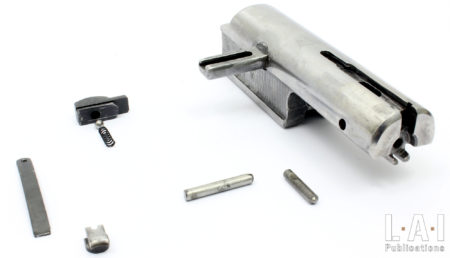

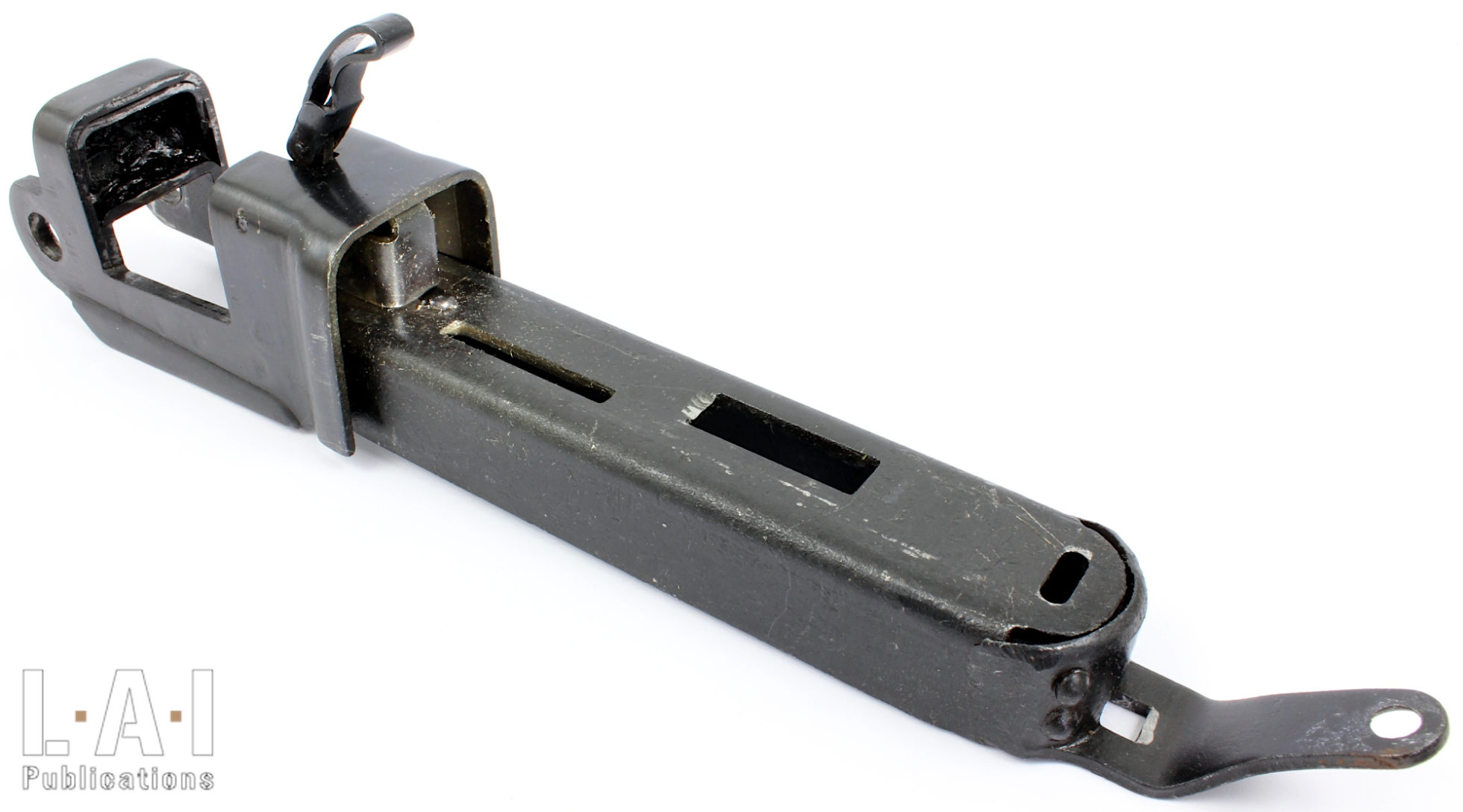

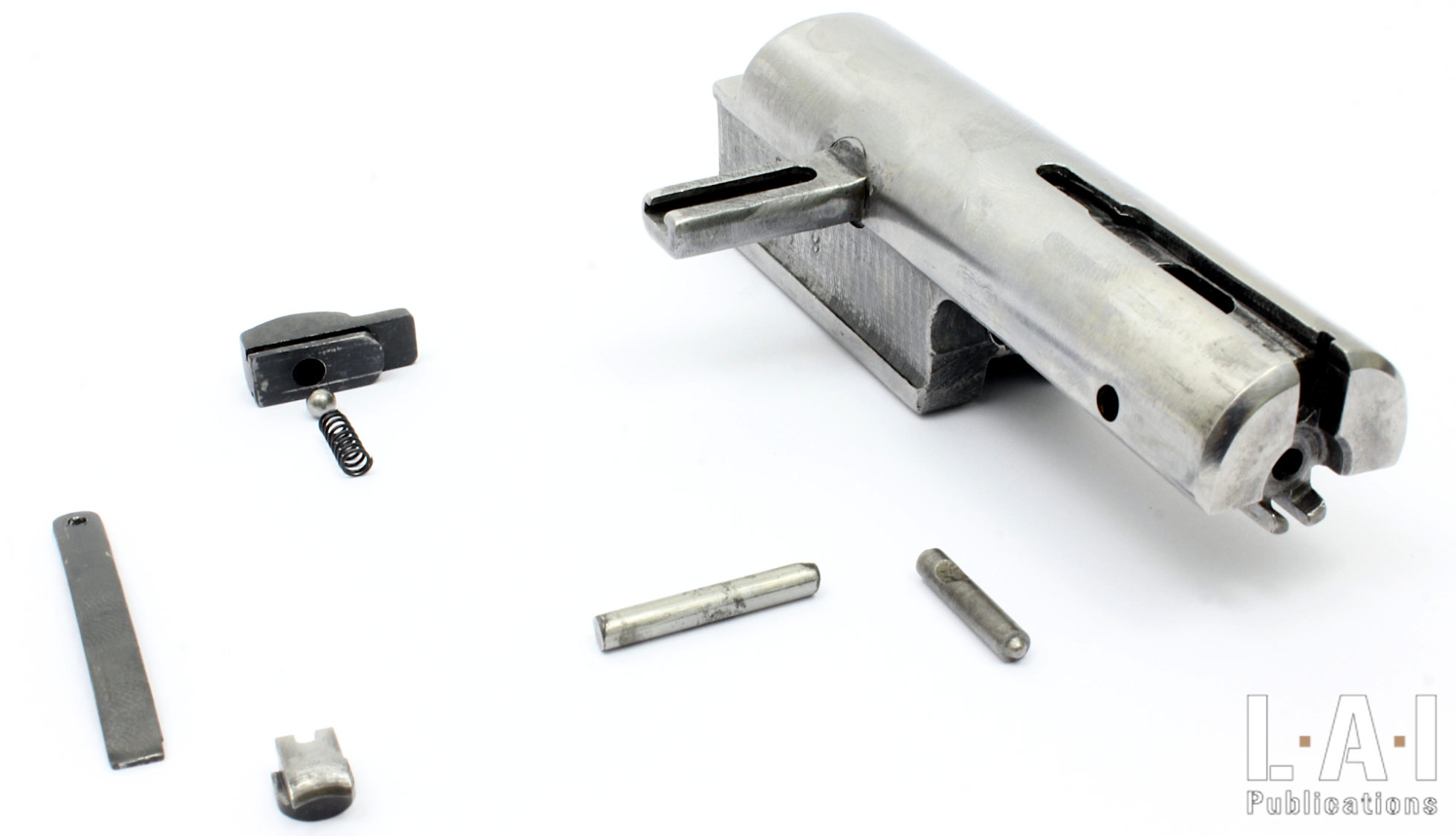

The bolt is forged and then machined. Its sides are hollowed out to facilitate its circulation in the bolt receiver in the presence of foreign bodies. The striker, a brought back part, is pushed and pined. This is a plus for manufacturing and maintenance. The cocking handle is a brought back and welded part (Pic. 15).

The weapon has a bolt buffer (Pic. 16). Made of a vulcanized fibrous material, it is intended to avoid premature wear of the lower receiver by the brutal stopping of the bolt with each shot. Especially since it can be noted that the bolt stroke is very short: it only slightly exceeds the magazine in order to take into account an ammunition. This explains an impressive rate of fire (announced at 1000 rounds per minute by the Soviet manual and measured at 1086 rpm on the short video available at the end of the article). It can be noted that this buffer was a source of supply problems during the war.

A young weapon for war

As mentioned earlier, the weapon is adopted only 6 months before Operation Barbarossa. Thus, when the USSR entered the war, the weapon was clearly not “matured”. This is the case for almost all armaments put into service: it is always necessary to make adjustments. The PPSh-41 would be no exception: but this adjustment would be made in a particular context that of an early entry into the war. This immaturity would also plant the seeds of another weapon: the PPS-43 (whose article is available here). This immaturity certainly related to (minor) manufacturing problems, but also to something that could not be attributed to G.S. Shpagin: the general concept of the weapon. In these dimensions, the PPSh-41 remains a “long” and heavy infantry weapon. With 842 mm long, it is less than 30 mm shorter than an AK-47… with a solid stock (Pic. 17)! The dimensional comparison between the two weapons is not trivial: it would be at the heart of some reflections in the USSR in the aftermath of the war. Without a folding stock, it is not adapted to the needs of vehicle crews.

However, the weapon would be corrected and improved by its designer. During the year 1942, it was a more suitable version that was put into production. Most of the changes were not directly palpable by the user (thickness of sheet metal, size of some parts). On the other hand, the adoption of a more convenient rear sights, a L-flipped two positions instead of the tangential sights usually encountered (which allows an adjustment up to 500 m – Pic. 18) on infantry rifles testifies to a rationalization of the concept of use. Similarly, the front sight hood, removable on the early productions, would be quickly welded so as not to be lost in the field.

Worldwide distribution

The weapon would quickly be put into production in the Soviet Union. Initially, it would be produced in several factories, using in particular the technique of subcontracting. Most of these factories were not initially dedicated to the production of armaments. These include:

- The ZIS (Завод имени Сталина – Zavod Imeni Stalina) automotive factory in Moscow, well known for its trucks. Its symbol is the ” З ” Cyrillic letter, which stand for a roman “Z”.

- The Scetmach factory in Moscow. Its symbol is the ” С ” Cyrillic letter, which stand for a roman “S”.

- The “Red” stamping plant (Красный штамповщик – Krasny Schtampovshik) in Moscow. The symbol is a Ш in a stylized К.

- The Avitek factory in Kirov, which as its name suggests, was rather specialized in aircraft production. Its symbol is the hammer and the sickle in a circle itself inscribed in a star with long lower branches.

- The Stalingrad / Volgograd tractor plant “F. Dzerzhinskly” where were also built of elements of T-34. The factory also served as a repair shop for these same tanks. The symbol is the letters Ф and Д in an oval or “FD”, the initials of F. Dzerzhinskly, hero of the October Revolution and the very young USSR.

- The industrial complex of Kovrov which includes many industries, as well as the factory where G.S. Shpagin worked (before leaving for Vyatskiye Polyany) with other Soviet designers. It is now called “Завод имени В. А. Дегтярёва” or “Factory V. A. Degtyarev”! The symbol is an arrow with empennage in a very vertically stretched oval.

- The precision instrument factory in Tbilisi (Georgia). The symbol is a 5-pointed star in a circle flattened and open on its lower portion.

- The train factory in Tbilisi (Georgia). The symbol is a 5-pointed star with “sticks” branches in a triangle.

Some sources also sometimes mentioned 4 other factories, all located in Leningrad:

- The Voskov instrumental factory (in fact, it is the former Sestroretsk arsenal), but there is no mention of the production of PPSh-41 or part according to our research…only the picture of a weapons marking “BB” (VV in Russian) in an article from the excellent Frank Innamico.

- The Leningrad Metallurgical Plant (Leningradsky Metallichesky Zavod), here too, no trace of productions found.

- The A.A. Kulakov Factory… no trace…of the factory! But the research is complicated (even in Russian), because Alexander Kulakov is a contemporary hockey player… not only an October Revolution hero…

- The production cooperative (Artel in Russian) “Primus”, which initially manufactured kerosene-pressurized stove.

Perhaps there was an ephemeral production in these factories of PPSh-41 or at least parts of PPSh-41, but it should be noted that from 1942, Leningrad is the epicenter of the creation and evolution of PPS-42 and 43 … in addition to being the object of one of the most violent sieges of the war as soon as September 8th, 1941.

Faced with the advance of the Germans, most of these factories would be moved about 1000 km east of Moscow, in the industrial complex of Vyatskiye Polyany. Its symbol is a 5-pointed star in a coat of arms. This industrial complex, which would become one of the high places of manufacture in the Soviet Union (where would be produced among other things RPK & Stechkin) and better known nowadays under the name of “Molot”, the hammer in Russian. G.S. Shpagin officiated there during the war and this plant became the main production site of the PPSh-41. The weapon would be produced to more than 5 million copies during the war. It was also believed to have been produced during WWII in Iran, at the Mosalsalsasi plant near Tehran. The weapon would be highly prized by soldiers on both sides and the Germans would even engage in some 9×19 conversion (the use in the German army would be under the codification of MP-717(r))

After the war, the weapon would continue to be produced in China (Type 50), North Korea (Type 49), Hungary (48M) and Poland (Wz.41). It would know a worldwide diffusion and would obviously be found on almost all the conflicts of the 20thand 21st century, from Saigon to Kabul via Tripoli.

Operation

The weapon operates from a straight blowback bolt. Firing is achieved from an open bolt, which makes it possible to interrupt the firing on an empty chamber, but also to considerably simplify the firing mechanism (cf. Chapter 6 of the Small Guide for Firearms for those who want more detail on this subject). The striker is permanently protruding inside the bolt faceThe bolt face is the part of the bolt which in set place the... More. Semi-automatic mode uses a disconnector, as on most handguns (Pic. 19). But here, the disconnection is produced on the front movement of the bolt and not on the rear movement, of course. This disconnector is simply made up of a lever that, when lowered by the bolt, pushes back the mobile spout of the trigger, which thus breaks its contact with the sear. The latter can then rise under the action of its spring. Thus, when the bolt is recoiled during the shot, it is again hooked by the sear. It is then necessary to release the trigger to ensure a reconnection of the trigger on the sear. During the automatic firing, the disconnector lever is simply disengaged forward: it no longer has a grip on the trigger spout.

A classic implementation

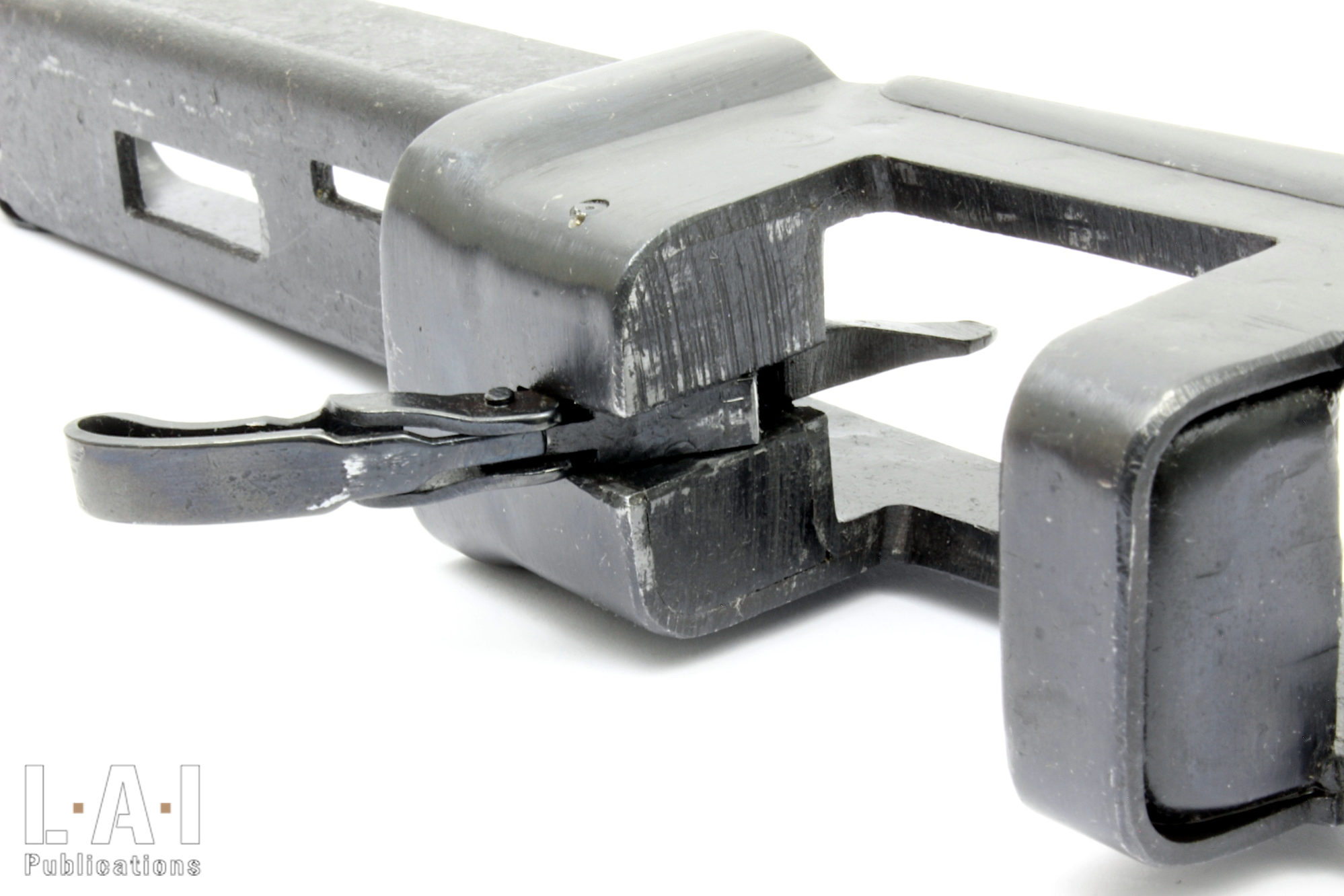

The implementation of the weapon is rather classic for this period. The cocking handle is arranged on the right side of the weapon. It has a safety cursor that allows the bolt to be secured to the upper receiver (Pic. 20). This cursor can be used in both bolt’s positions: at the rear (cocked) or at the front. The weapon doesn’t have any other safety device. The firing selector is located inside the trigger guard: towards the rear, it switches the weapon in semi-automatic mode, towards the front, the weapon shots in automatic (Pic. 21). The magazine catch, placed at the back of the magazine well, has an articulated lever that can fold backwards along the stock (Pic. 22). This provision – also present on the SVT-38 and 40 – makes it possible to erase this command and avoid untimely releases but also to position the hand under the stock without fear of activating the said catch. The introduction of the magazine is done straight into the magazine well. This is probably the most “complex” point: the guidance being provided by a rail on the back of the magazine and not by the outer walls, it is necessary to “guess” the placement of the groove (Pic. 23). This is not really difficult but requires more attention than for the majority of magazine wells.

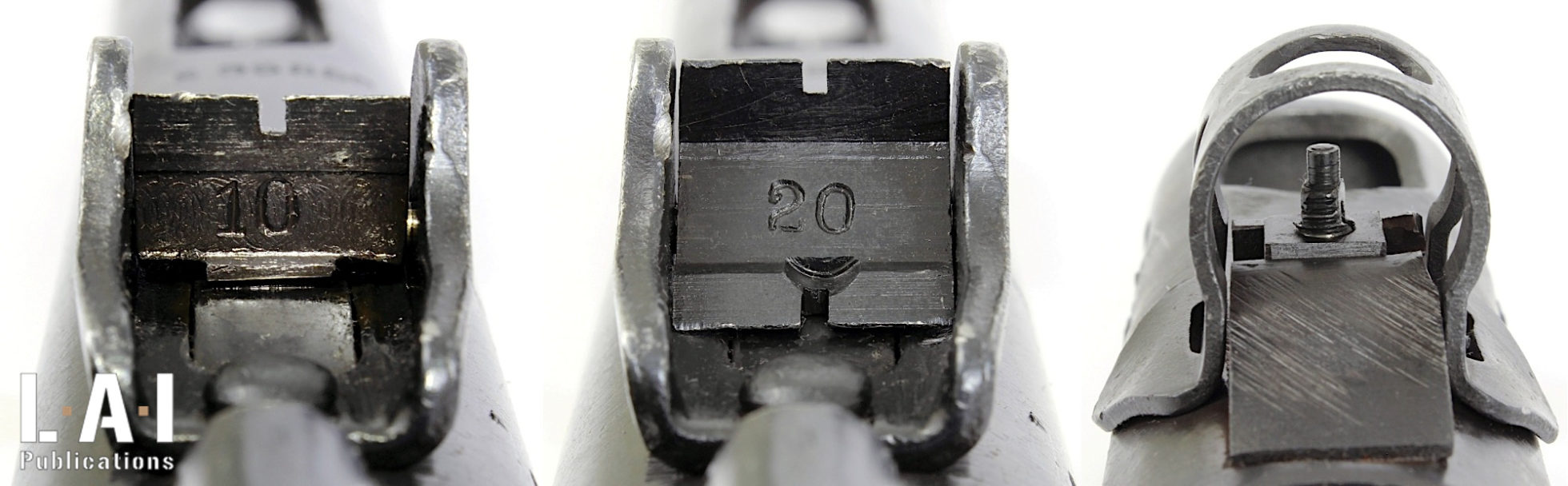

The sights consisted of a U-shaped notch and hooded front sight post (Pic. 24). After a first version with a tangential rear sight graduating up to 50 decameter (or 500 m), the L-type flipping rear sight has two positions 10 and 20 in decameter, or 100 and 200 m. The front sight post has the particularity of being adjustable in both elevation and direction, a rare luxury for a SMGSubMachine Gun More, but ultimately even for an infantry weapon of that time (Pic. 25)! We also find the very peculiar Soviet system (in a way already present from the DP LMG) where the post is screwed to obtain the adjustment in elevation and its support pushed in its base to obtain the adjustment in direction.

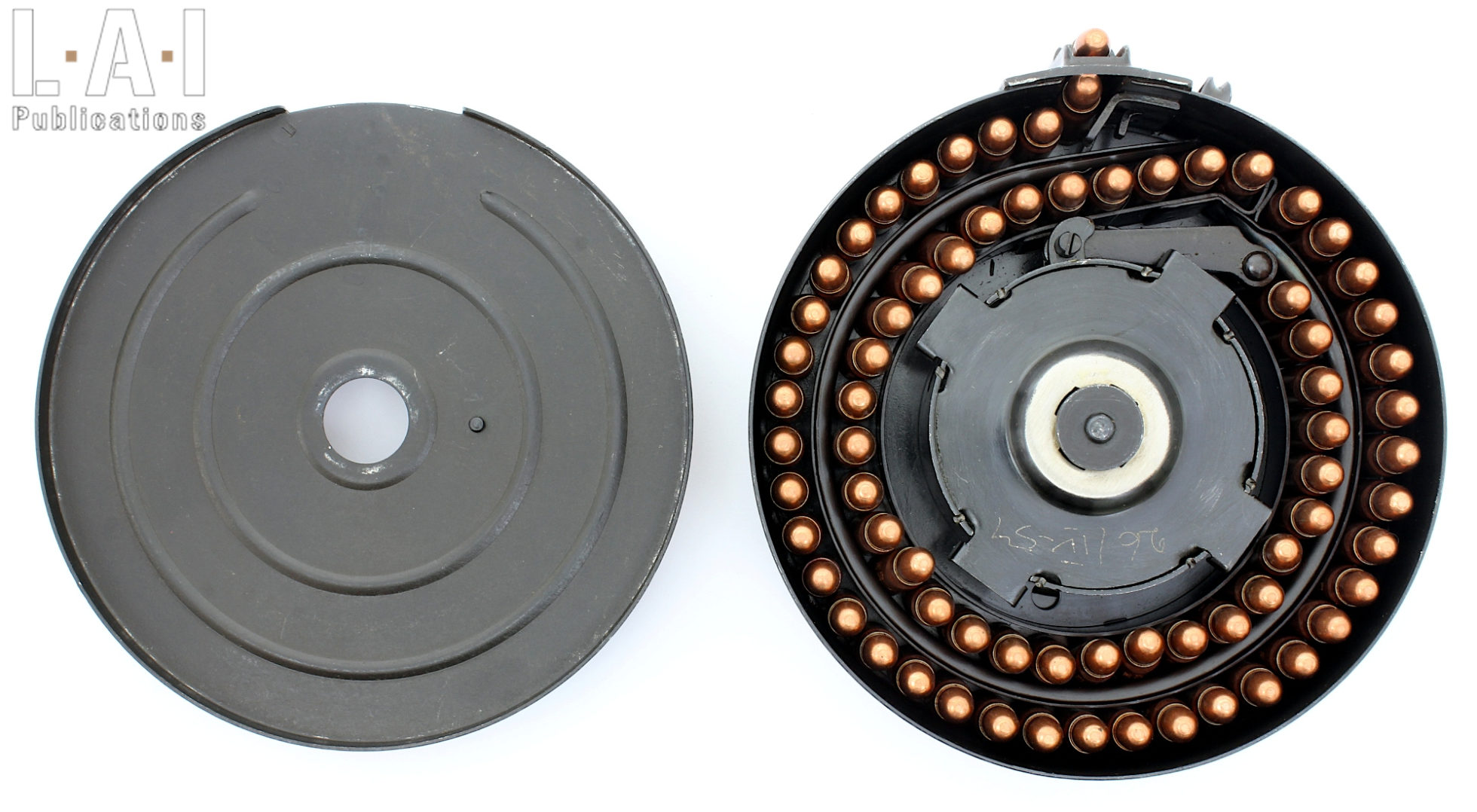

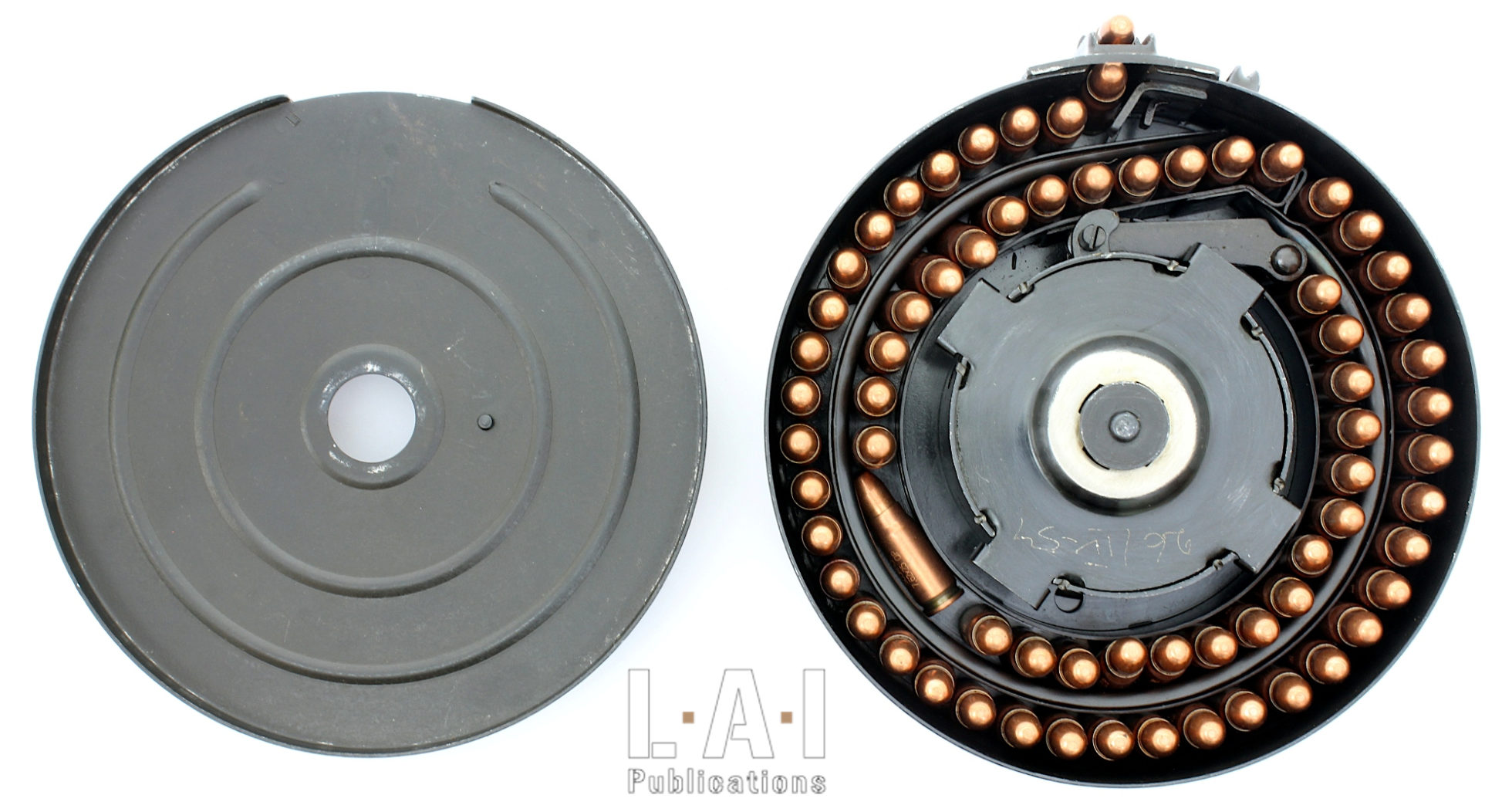

The loading of drum magazines requires care and calm: after pushing back the central button to unlock the closing latch, the front plate is removed. We can then wind, notch by notch, the mechanism of pushing the cartridges up to the stop. After turning the tray in the “counter-clockwise” direction, you can arrange the ammunition on the tray, head down. The game will then consist in placing the ammunition without ever dropping it… like a series of dominoes. When the ammunition falls, there is nothing dramatic, but you still have to reposition it carefully… big fingers are going to have a rough time (Pics. 26 and 27)! Once the magazine is filled, the plate is replaced carefully: then press once again the button of the magazine to replace the latch. Be careful, it is the action of pressing the button that frees the mechanism of pushing cartridges: any untimely triggering of the mechanism with the finger inside will result in an “eating” of the fingers in a proper and formal way. In particular, the magazine should not be placed on a flat surface during these operations, or at least care should be taken not to exert excessive pressure.

The loading of single-feed double-stack magazines is done in a “classic” way for this type of magazine: the ammunition present in the magazine (or the follower) is pushed with the ammunition to be introduced, then it is dragged backwards (Pic. 28). It should be noted that the curvature of the magazine facilitates loading operations compared to the straight magazines of a STEN, a MP-40 or a MAT-49. Thus, it is possible to fill the magazine at its maximum capacity (35 rounds) without the help of a loader. However, loaders do exist (Pic. 29). The one at our disposal slips on the return of sheet metal present on each side of the magazine and originally intended to close the magazine well usually filled by the drum magazine. The purpose of this provision is to prevent the introduction of foreign bodies from the weapon that could generate jams.

Let’s take the opportunity here to mention that if the 71-rounds drum magazine has acquired a legendary status, it is however less practical than the curved magazine of 35 rounds. This drum magazine certainly has two advantages:

- A large firing capacity immediately available

- A reduced ground clearance, always a plus for shooting from a prone position.

But it also has several disadvantages:

- Laborious to load on the field (always consider the chaos of a war zone, cold or wet hands).

- More complex, therefore less reliable and more expensive to produce.

- Bulky for transport: the compactness in height is obviously lost by an increase in width.

- Heavy (excluding ammunition): 1.029 kg, compared to 0.340 kg for a smooth curved magazine (thick sheet) of 35 rounds and 0.249 kg for a grooved curved magazine of 35 rounds. This gives a ratio of 14.49 g of magazine per cartridge for the 71 rounds, against 9.71 g for the smooth curved magazines and 7.11 g for the grooved curved magazine. That’s double the weight of the lightest magazine!

- As already mentioned, it requires a specific magazine well, open on the sides, ultimately less convenient to use.

- Finally, it tends to push to excessive cartridge consumption, although this last point is to blame on the lack of discernment of the user and not on the magazine …but still, it’s a consequence of its capacity!

Thus, it is not surprising that the Soviets introduced as early as 1942 a more “conventional” curved box magazine, double-stack and single fed. They would even abandon the drum magazine with the PPS-43 which would use a better designed curved magazine … but not necessarily more solid according to some feedback. Be careful not to confuse solidity and reliability here (Pics. 30 and 31)!

Disassembly

As usual, the weapon is cleared. In this case, the magazine is removed, the bolt is cocked, the emptiness of the magazine well and the chamber are inspected. Then by choosing a “safe” direction (i.e. capable of absorbing an accidental discharge while minimizing the risks), the bolt is returned forward. We then push the disassembly pusher forward and rotate the upper receiver… as on other more contemporary productions! Thus opened, the weapon presents the bolt, its recoil spring and the buffer. To remove the assembly, the bolt is moved back slightly, then the whole is rotated upwards (Pic. 32). The bolt, recoil spring and buffer can be then separated.

To this is added the disassembly of the magazines. The drum magazine is disassembled for maintenance as well as for loading. The curved box magazine is disassembled in a very conventional way: the magazine floorplate lock is pushed inwards, and the magazine floorplate is slide forward.

At this point, the weapon is disassembled enough for “routine” maintenance. To go further, it will be easy to remove the trigger mechanism and the stock (one screw present at the tang of the lower receiver) and to deposit the extractor of the bolt. For the extractor, with the help of a suitable tool, it is simply necessary to lift the front part of the extractor leaf-spring and then push it forward. Once the leaf-spring is removed, the sliding-type extractor comes out of its slide (visible on Pic. 07 and 15).

Finally, you can remove the barrel: to do this, simply remove the rocking axis from the receivers. As mentioned earlier, the weapon has undergone modifications (in fact, simplifications) during its production. Thus, on the two copies at our disposal, the rocking axis of the frame is one of the differences observed (Pics. 33 to 35):

- On the 1942 copy, it is a hollow axis secured by an expansive “counter-axis”. Here, it is therefore appropriate to drive the counter-axis first, and then, in the other direction, to drive out the hollow axis.

- On the 1945 copy, it is a solid axis with a groove in its middle. This groove makes it possible to secure the axis by means of a cylindrical spring inserted into a hole in the upper receiver (visible in Pic. 08). In this case, it is simply necessary to drive the solid axis by exceeding the retention provided by the spring.

It would seem that the “solid” axis actually made a “come back” in production: used on very early production, it was only abandoned temporarily before resurfacing at the end of the conflict.

Once the axis is disassembled, one ends up with the upper receiver which contains the barrel and the lower receiver. The removal of the barrel is done by the rear of the upper receiver: it may be necessary to “peel it off” from its receiver by tapping on the muzzle with a suitable tool (that is, in a material that is not likely to damage the muzzle of the barrel).

It is not wise to go further in the disassembly for routine maintenance: most of the axes are stopped by a punched point. In addition, the accessibility for cleaning is rather good, not to say excellent if we have disassembled all the parts mentioned above. Moreover, all these operations are quite simple.

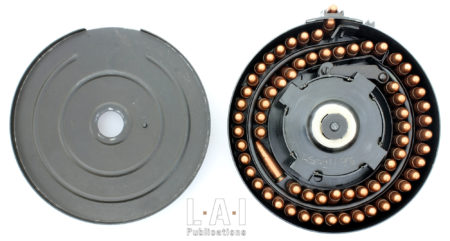

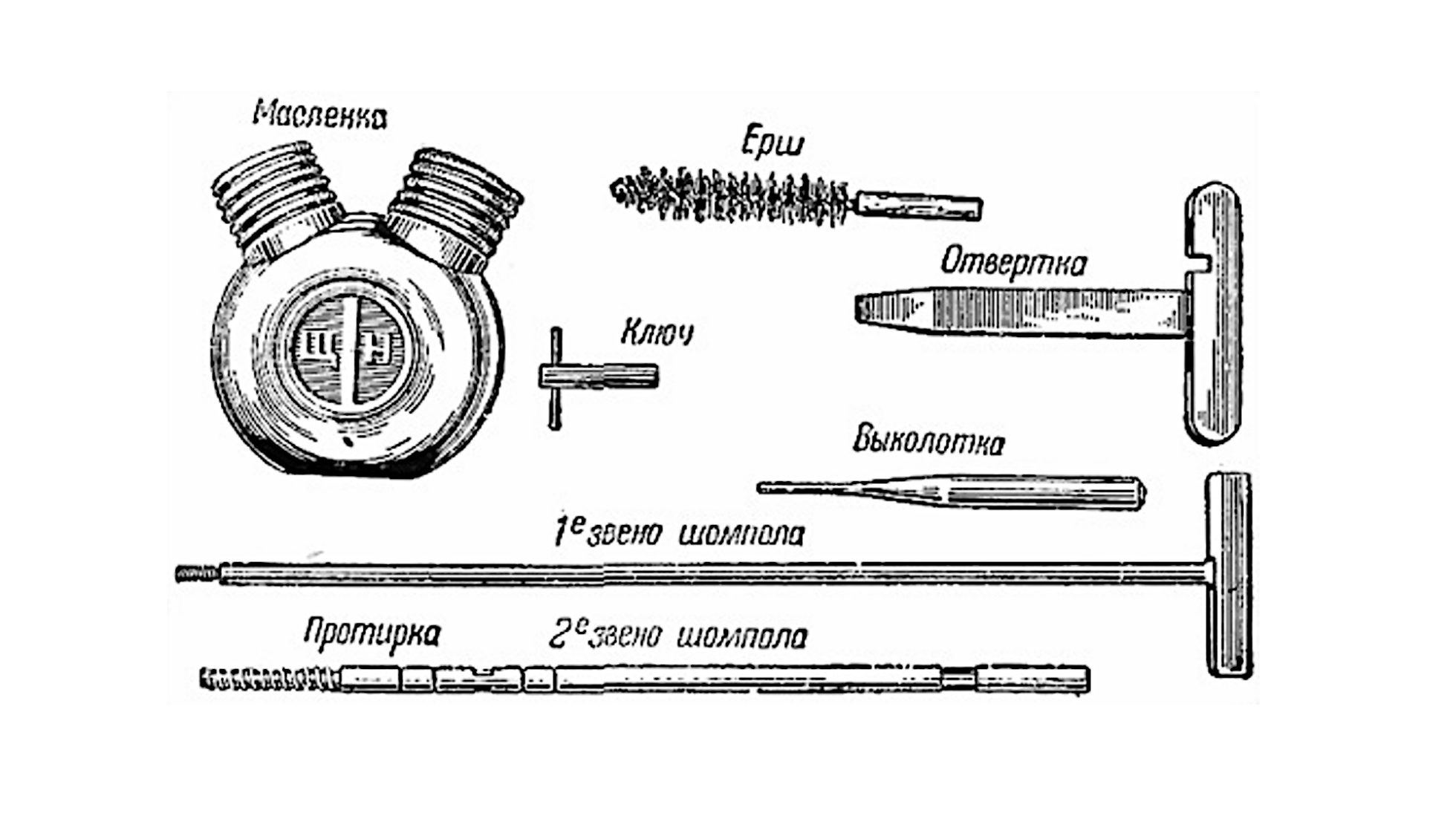

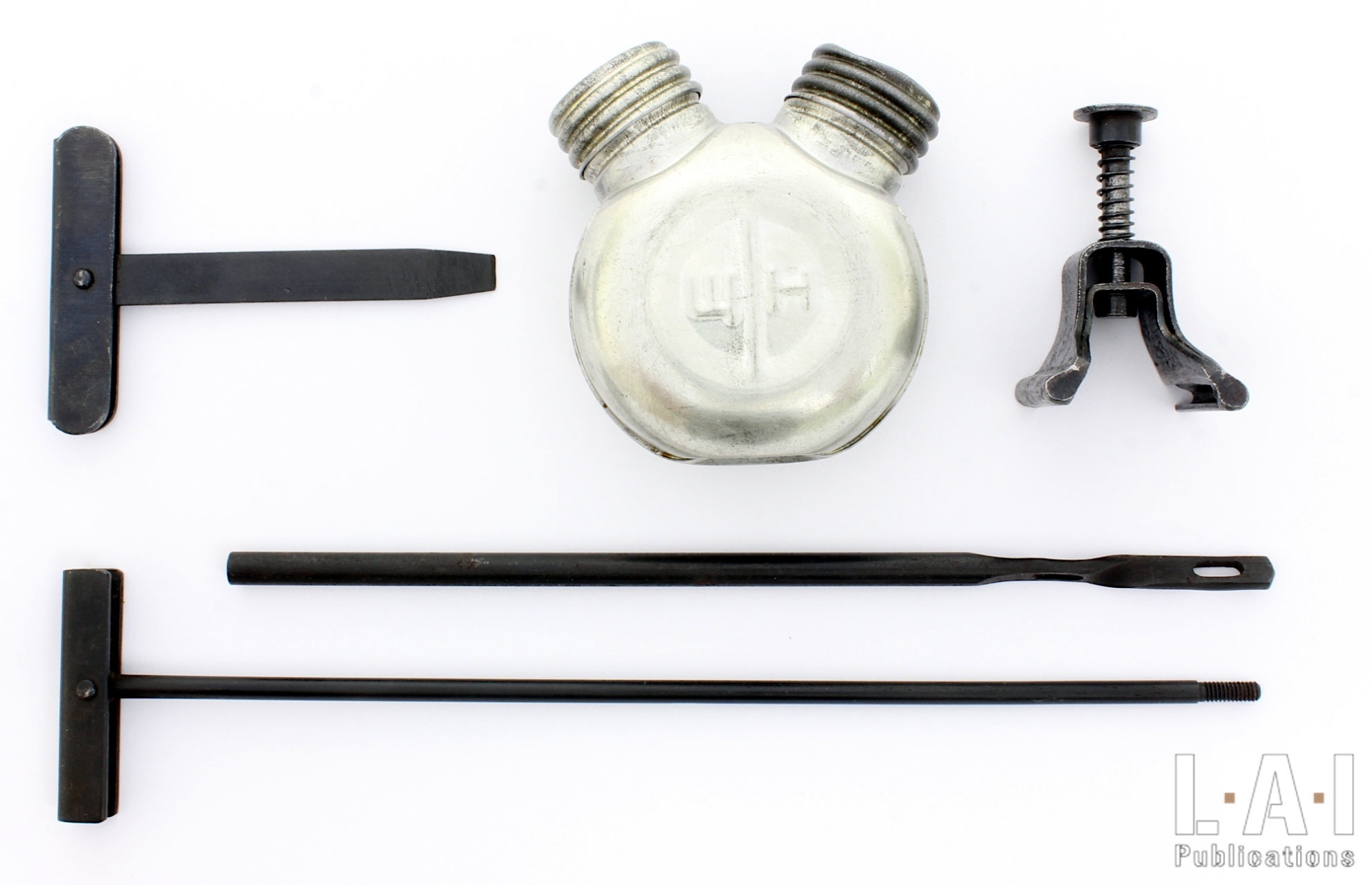

Finally, the weapon has in its butt plate a hatch to store part of the cleaning kit, and in this case, the cleaning rod (in two parts), the screwdriver and the brush. The presence of a solid rod on the weapon is always a plus for this type of weapon: in case of brass sticking into the chamber (with tearing of the case’s head by the extractor), the rod is essential to remove the case from the chamber… and return the weapon to service (Pic. 36 to 38).

Shooting

While shooting, the grip is disconcerting: you literally do not know what to do with your off-hand! On the magazine? On the barrel shroud? On the front part of the stock behind the magazine? The magazine tends to establish itself as a makeshift grip although the stock is presented as a frequent catch in the service manual. This is especially true with a 35-rounds magazine. But the solution is only mildly satisfying. It is curious to see that Soviet weapons from the beginning of WWII sometimes (often?) have a “special” grip: the DP, the PPSh-41 and even the TT-33, some people even find the narrowness and slope of the grip not so good! You probably can’t be good everywhere…

The stock, the sights and the trigger release are comfortable. We feel that we will easily reach the target … and it is! In semi-automatic mode the kneeling figure target is reached 100% of time with disconcerting ease at 100 m. In bursts, the beast is less convenient: the very (too) high rate of fire combined with a risky grip tends to make the operation more delicate than on most other SMGs. However, let’s remain lucid, it is a 7.62×25 SMGSubMachine Gun More, not a 7.62×51 “Battle Rifle”. The burst remains largely controllable.

On our copy in firing condition, all incidents of “miss-fire” encountered are related to our drum magazine, which tends to produce “low dives”. We specify “miss-fire” because we also had many bursts firing in semi-automatic mode. The cause comes from a random adjustment of the parts of this copy: the bolt tends to pass slightly “above” the trigger point of the disconnector. Let us be careful not to pronounce a judgment on the examination of a single copy 67 years after its production! Let us emphasize here the pleasure that we had when firing a SMGSubMachine Gun More of this period when it is possible to adjust the sights, which avoids the usual aims lead, always painful and undoubtedly problematic in operational situation.

Conclusion

Highly appreciated by soldiers from both sides, the “PaPaSha” stands among some of the most legendary weapons. If it does not demerit from a technical point of view, let us not lose sight of the fact that circumstances have largely contributed to its fame. If in the panel of submachine guns of WWII, it has a certain “normality”, it was in fact late for its general ergonomics (too long, too heavy) and early for its manufacturing methods. As it is, we undoubtedly favor the PPS-43 whose article is available here.

Arnaud Lamothe

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!

Source:

D.N. Bolotin, “Soviet Small-Arms and Ammunition”.

Article by Frank Innamico on PPSh-41 (as visited on July 7th, 2022):

https://sadefensejournal.com/the-soviet-ppsh-41/

Post of a Russian forum on the “Red” stamping plant in Moscow (as visited on July 7th, 2022):

https://podstakanoff.net/forum/viewtopic.php?t=264

Soviet service manual (in Russian) (as visited on July 7th, 2022):