White phosphorus 7.92 mm German ammunitions

Between 1898 and 1945, the German service rifle cartridge was the excellent 7.92 mm caliber cartridge for a case length of 57 mm. The “7.92 mm” caliber refers to the average diameter of the barrel matching the ammunition adopted in 1888: called “8×57 I” by the CIP standard, the barrel has a diameter of 7.80 mm in between lands and 8.02 mm in between grooves for a bullet diameter of 8.09 mm. This was replaced in 1905 by the so-called “Spitzgeschoß” ammunition, also called “S”. In addition to a new drawing now familiar to all shooters (pointed cylindrical-ogival with flat base), it saw its caliber increase: 7.89 mm in in between lands and 8.20 mm in between grooves, for a bullet diameter announced at 8.22 mm.

The Germans mainly used three materials to make the cases. Were successively and then simultaneously employed:

- Brass: alloy of copper and zinc conventionally in a proportion of 67% copper and 33% zinc.

- From the second half of the First World War, steel protected by electrolysis against oxidation thanks to a copper plating (varnished or not).

- And finally green lacquered steel cases which appeared in the 40s.

Spitzgeschossoß mit Phosphor and Flugzeubrand ammunitions

The bullets offer a remarkable multitude of variants and compositions, a sign of the dynamism and fruitful spirit of the German armament engineers. They started to develop phosphorus ammunition as soon as WWI. For the record, white phosphorus, from the Greek purophoros “which carries fire”, is a solid chemical compound called “pyrophoric”, that is, which ignites spontaneously when in contact with the oxygen from the air. Its combustion gives off a very high temperature (said as being up to 2,760 °C) as well as a cloud of very dense white smoke, which makes it a frequent use for the composition of smoke ammunition (Pic. 1). An early version of an ammunition containing phosphorus seems to have been inspired by British .303 caliber ammunition frequently referred to as “smoke-tracers“. The German ammunition developed in 1916, it was called “Pr.L” (probably for Phosphor Leuchtspur, or “phosphorus tracer”) and quickly gave way to another version called “S.Pr” Spitzgeschos mit Phosphor : pointed phosphorus bullet. These cartridges were mainly intended for weapons embedded in airplanes or Zeppelins to ignite fuel from allied aircraft tanks or hydrogen balloons from artillery control balloons.

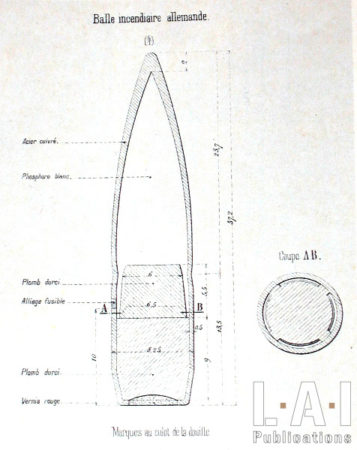

A French manual of “information on foreign cartridges that can be found on the battlefields published on March 19th, 1920, by the artillery section of the Ministry of War” allows us to observe a sectional plan of this incendiary bullet “S.Pr. “. It has a hardened lead core topped by a steel core, itself topped by the incendiary charge of white phosphorus. This arrangement is logical with regard to external ballistics, the center of gravity must be towards the rear of the bullet for reasons of flight stability. A careful examination makes it possible to observe the presence of a hole “sealed” by a drop of Darcet alloy. It is a low melting point alloy (95 °C), consisting of 50% bismuth, 25% lead and 25% tin, used to make safety fuse elements. This point is visible on the left on the diagram, at the level of the steel core. When the ammunition is assembled, this seal is covered by the neck of the case, which provides it with good protection during handling. At the time of firing, the operculum of the Darcet alloy is melted by the rise in temperature related to the friction of the bullet jacket on the bore of the barrel. Thus, when the bullet leaves the barrel, the phosphorus begins to burn in contact with oxygen in the air. This has two consequences:

- The combustion of phosphorus produces a bright glow and as mentioned above, a very dense white smoke. Thus, the trajectory of the bullet is materialized by the emission of glow and smoke: the bullet behaves like a tracing ammunition, and more particularly as a “smoke-tracer” ammunition as seen on the .303 British ammunition.

- The heat and inextinguishable flame of phosphorus in the terminal phase and during impact easily ignites all the fuels encountered. We are thinking in particular of the fuel of land or air vehicles but also of the gas of the various Zeppelins and observation balloons then in use as already mentioned above. Since the emission of the flame is constant on the trajectory of the useful range of the ammunition, it is thus not necessary to dislocate the bullet on a hard surface to initiate a fire. This arrangement makes sense in the mixing of cartridges on machine gun belts: some ammunition perforates, others ignite.

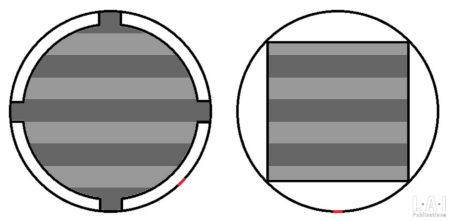

The contact between the phosphorus contained in the bullet and the ambient air outside is ensured by the hole closed by the Darcet alloy in the jacket, the steel core is not strictly cylindrical. Our research has determined that two variants appear to exist:

- A core with a truncated profile and touching the jacket only in four points, the rest of the core having a smaller diameter. (Pic. 2)

- A core of square section: by definition the square has its four angles in a circle the diameter of its diagonal. This may be a simplification of production. (Pic. 3)

We can thus wonder about the vocation of this steel part. This seems very light to officiate as an armor-piercing device (the ammunition is not presented as “armor-piercing”), although the presence of a steel element is often a “plus” in terms of perforation. However, its positioning within the bullet corresponds perfectly to the part with the orifice allowing the combustion of phosphorus in flight. Therefore, it is not strange to assume that, in reality, the realization of this part of the steel core stems solely from the “incendiary in flight” vocation of the ammunition. Making this same part out of lead is riskier in terms of the reliability of the device: since lead has a low melting point (about 327.5 ° C), the combustion of phosphorus could quickly melt it. The lead could then leak or plug the hole with somewhat problematic consequences in terms of efficiency. We invite you to consider this as a hypothesis, and as always, to form your own opinion on the issue! For the rest, as it is often the case, the device seems extremely well studied. However, the whole can seem fragile during manipulations: an accidental shock on the thin jacket of the S.Pr. bullet can expose the phosphorus, which seems to guarantee the apocalypse! Finally, at the time of balloons and very fragile wood and canvas planes the presence of a perforating core was not fundamental (or even counterproductive in the case of balloons!) and the choice was probably made to favor the weight of the phosphorus load which would have been reduced if the bullet had contained a substantial hardened steel core. Finally, the end of WWI saw the birth of a truly “armor-piercing and incendiary” ammunition called “Flugzeugbrand” or “F”, which means “incendiary for aircraft”. Its perforating core, of a consequent size, is surmounted by a low load of white phosphorus. Unlike the S.Pr, this charge is only released by tearing the jacket on impact. Similarly, unlike the F, the S.Pr. steel-jacket bullets (plated with copper, tombac or maillechort) containing just a lead core and an incendiary charge would have tended to fragment against the structures of the new aircraft, without penetrating or generating fires and damage sufficient to shoot the machine down in flames. Because of course, the progress of aviation in the interwar period had made aircrafts stronger. Cockpit were often armored, and ordinary bullets did not penetrate special steel sheets either.

Phosphor mit Kern ammunition

At the end of the 30s, phosphorus incendiary bullets were redesigned, with an ammunition that finally constitutes the synthesis of the S.Pr. and the F. This new version of incendiary cartridge for the Air Force was called “Phosphor mit Kern” or P.m.K. The “K” of the name indicates the presence of a steel (armor-piercing) core, in German “Stahl Kern“. Here, the steel core is treated in such a way as to increase its perforating capacities. These are systematically mounted, with very few exceptions, with brass cases. They can be identified by:

- A red band which bars the head on the first variation.

- A fully tinted black primer (rarely observed).

- A black ring on the perimeter of the primer, the most commonly encountered variant.

The bullet with a length of 37.30 mm weighs 10.15 grams. It contains a hardened steel core of 2.4 grams of pointed ogival shape with a basal peduncle. This peduncle of smaller diameter than the head of the bullet bathes in a charge of 0.5 grams of white phosphorus. (Pic. 4) It is noted that the presence of the armor-piercing core constitutes a structural reinforcement for the bullet, which in addition to giving it an increased perforation capacity, can boast a solidity when manipulated much greater than the S.Pr. We find the lateral orifice of the bullet sealed by a Darcet alloy point as on the S.Pr.

The cartridges we intended for testing were manufactured in 1942 and are of the 6th batch of the year, the case is made of brass as indicated by the marking “S*“, the code “emp” designates the manufacturer, the factory Dynamit A.G., vormals Alfred Nobel & Co, Werk Empelde bei Hannover. (Pics. 5 and 6). This is a “tropicalized” version called “P.m.K. Trop.”. The notion of “tropicalization” indicates the presence of a crimping varnish at the junction between the bullet and the case reinforcing the sealing for specific uses in tropical areas or to cope with sudden changes in altitude and therefore support extreme thermal amplitudes.

The discovery of a handful of these cartridges provided an opportunity to test these venerable relics of the military industrial heritage of WWII. As it holds an adequate authorization to trade this kind of material, this test was carried out in compliance with weapons legislation in France. Keep in mind that as for French legislation, those incendiary cartridges are classified in the “A-2-2” category and therefore are prohibited from detention by civilians.

As a target we used a few small butane cartridges made of thin sheet metal. These were placed on a stump itself placed against an industrial oxygen cylinder that had been used as a target for years. The latter is intended to deform and fragment the bullet by its resistance to penetration, in order to facilitate the instantaneous release of phosphorus. The use of these gas containers allows us to simulate, in a controlled way (no liquid projection) and economically, a fuel tank. One could, of course, object that the ignition conditions of gas and liquid fuels are different: certainly, but in reality, the firing of the gas requires a mixture of fuel (gas) / oxidizer (air) probably more complex to coordinate than the firing of vapors of ordinary gasoline, contained in a tank. In the past, we have conducted similar tests with tracing ammunitions of the same caliber (S.m.K L’spur), without the systematic firing of the gas being observed.

A Mauser K98 k was used for the test and the shooter placed himself at a reasonable distance to avoid any risk of injury. The shooting range being an old gravel pit, the ground is made of pebbles and therefore limits all risk of fire.

During the shot, the phosphor ignited the gas escaping from the container easily pierced by the bullet, making a beautiful fireball. Modern technology allowed us to film the test and the frame-by-frame viewing proved to be very informative!

On one of the screenshots (Pic. 7) we see very clearly the rotation of the bullet induced by the grooves and materialized by the sparkle of the phosphor burning by the lateral orifice of the bullet. The intensity of the flame increases from a few meters, and its color becomes more reddish. The passage of the bullet through the cartridge releases then ignites the gas. (Pics. 8 and 9).

This result allows us to draw some interesting conclusions: despite being 80 years old, these cartridges are still perfectly functional, and their incendiary power seems intact. Also, the perforation force of the core of only 2.40 grams is not negligible. With an endowment of this kind of cartridge the slightest infantryman armed with a simple rifle could inflict immense damage on the opposing vehicles and thus generate a significant panic. Regarding its use in the context of aerial combat, let us remember that the rate of fire of an MG 81 varies between 1400 and 1600 rounds per minute, a rate of fire to be doubled for the twin version of the weapon qualified as MG 81 Z (Z for Zwilling “twinned”).” The rate of an MG 15 machine gun is 1000 rounds per minute on average. Therefore, the passage for one second in the axis of fire of an aircraft machine gun sends into the target between 53.3 bullets in the case of an MG 81 Z (twinned) and 16.6 bullets in the case of an MG 15. Even if the belts are mixed (1 incendiary on 5 cartridges) this implies that the tanks, the engine or the crew of the opposing aircraft are guaranteed to take between 10.6 and 3.3 armor-piercing-incendiary bullets! Guaranteed result! One question remains unanswered for us: what was the technology used to introduce solid phosphorus while preventing it from igniting during manufacturing operations?

A bit of military archaeology

On the night of June 14th to 15th, 1944, a German Dornier Do. 217 K-3 bomber N°4749 registered 6N+HR of the Kampfgeschwader 100 (KG100) crashed. This aircraft had taken off from Toulouse with two other identical aircrafts (N°4555 and N°4748) earlier in the evening to bomb the Allied fleet in Cherbourg, including using guided gliding bombs “Fritz X” or Hs 293. The 4748 was shot down by the allied Anti-Aircraft Artillery. The other two appear to have strayed that evening and crashed together in the middle of the night on the return flight under undetermined circumstances. The Do. 217 K-3 N°4749 collided with Mont Sacon (Tourroc) in the central Pyrenees after diverting from its route towards Toulouse probably because of a side wind.

The crew consisted of:

- Pilot: Fw (Adjudant) Stoll Rudolf.

- Kampfbeobachter (observer): Lt (Sous-lieutenant) Sühnel Rudolf.

- Bordfunker (radio): Uffz (Sergeant) Welte Erwin.

- Bordwart (flight engineer): Ogfr (Master Corporal) Wettermann Johann.

There were no survivors.

Technical data of the Dornier 217 K-3 version:

- Weight (empty – maximum): 9.45 tons – 16.57 tons.

- Length: 17 m.

- Wingspan: 24.8 m.

- Height: 5 m.

- Engines: 2 x BMW 801 D with 14 cylinders arranged in a double star.

- Power: 1,700 horsepower per engine.

- Maximum speed: 533 km/h.

- Maximum autonomy range: 2,100 km.

- Maximum ceiling: 9,000 m.

- Crew: 4 men.

The on-board armament consisted according to the versions and models of:

- 2 MG 131 machine guns of caliber 13×64 mm B (one in the rear turret, one in the ventral turret).

- 3 MG 15 machine guns of caliber 7.92×57 mm IS (one on each side of the cockpit).

- 6 MG 81 machine guns of caliber 7.92×57 mm IS (one machine gun paired in the nose of the aircraft).

- Up to 1.5 tons of bombs on the outer pylon, which could include 2 radio-controlled SD 1400 Fritz X gliding bombs or two Henschel Hs 293 missiles.

- Up to 3 (2.5) tons of bombs in the bomb bay.

The secondary armament on board consisted of a Mg-81 Zwilling machine gun (twinned) in the nose and various Mg-81 and Mg-15 in turret or firing through portholes on the sides of the cabin. These machine guns were chambered in 7.92X57 IS and fed by belts mixed with various types of bullets including P.m.K. alternated with tracer cartridges at night.

In 2013 an archaeological expedition was organized under the patronage of the Cultural Regional Directorate of the Ministry of Culture. A large quantity of remains were discovered including cartridges deformed and twisted by the violence of the shock. Here you will find the link to an article about this expedition (in French).

Autopsy of a P.m.K. cartridge.

The reasoned examination of this cartridge collected on the site of the air crash of a Dornier Do. 217 K-3 is rich in lessons. (Pic. 10) First of all, it can be seen that the cartridge is strongly deformed and still loaded but that the bullet jacket has not torn, proof that its structure is solid enough in relation to operational needs. It can also be concluded that it was probably immediately removed from the terminal blaze. We also notice a more original detail, the incendiary composition of white phosphorus ended up escaping from the base of the bullet where it was contained (the thin jacket having probably given way because of oxidation) and is present in the form of a blister of now inert white material. Since white phosphorus has the property of burning in contact with air, it is surprising that the heat of combustion of the latter did not communicate its heat to the powder contained in the case, it can almost certainly be said that the cartridge was buried underground, and that the rupture of the jacket took place in an oxygen-free environment (buried), which allowed the flow and alteration of white phosphorus without its firing, probably a long time after the crash of the plane.

Let’s continue our investigation by performing the autopsy of the cartridge!

Logic would have it that we are dealing with a “P.m.K. v.” type cartridge the letter “v” for “verbsserte” (“improved” in Goethe’s language) whose name indicates an optimized loading of the cartridge with “Nitropenta Gewehr Röhrenpulver”, a double-base propellant powder in the form of black cylindrical rods. (Pic. 15) Intended for aviation machine guns, the Nitropenta develops a pressure (and speed) clearly superior to “ordinary” ammunition. The power gain is sometimes advertised at about 115 m/s of additional speed, sometimes at 500 bar of additional pressure, or even 10% and sometimes even 30% of additional pressure. For the record, the proof pressure of the CIP standard is 25% higher than the average maximum pressure allowed for an ammunition of this caliber. It is this kind of very complex cartridge that should in theory have equipped the on-board weapons. The aircraft’s defense weapons were often difficult for crews to access, so during combat, so it was vital that the weapons functioned flawlessly. The use of tropicalized cartridges guaranteed seals, the nitropenta charge made the operation of the weapons more regular and finally, the brass cases avoided the sticking of the latter in the chambers and limited the stops.

However, by emptying the cartridge we discover a classic nitrocellulose filler in the form of square grains! Gunsmiths in the Toulouse Francazal air base housing KG 100 appeared to have suffered shortages of supply of “v” cartridges only to be forced to feed the belts with cartridges less compatible with the operation of the MG 81 and MG 15 machine guns. (Pic. 16)

The powder recovered from the cartridge easily ignited and did not seem spoiled by its long stay underground!

By disassembling the bullet, made possible and much easier by the decomposition of the white phosphorus charge, we were able to recover the specific armor-piercing core of the P.m.K. cartridges thus confirming what the presence of a black initiation ring on the case’s head still visible despite the outrages of time suggested! (Pic. 17) The cutting of two other bullets was carried out after prior firing of their white phosphorus charges.

This study ends with the hope that never a time as awful as a war will come to mourn humanity, but I am afraid unfortunately that this is only wishful thinking! Our tests have only a technical and historical purpose, far from us the idea of any nostalgia, only the fascination for military technology animates us!

Gilles Sigro-Peyrousère

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!

Reminder: all the operations described in this article have been carried out by experienced professionals and duly authorized in metropolitan France. The handling of these materials is highly dangerous and illegal for civilians.

Article on the archaeological research of the crash site (in french):

https://aerocherche.fr/pdf/DO217_FINAL.pdf

Annual subscription.

€45.00 per Year.

45 € (37.5 € excluding tax) Or 3,75€ per month tax included

- Access to all our publications

- Access to all our books

- Support us!

Monthly subscription

€4.50 per Month.

4.50 € (3.75 € excluding tax)

- Access to all our publications

- Access to all our books

- Support us!