A 9mm Largo experimental pistol attributed to Corominas

The north of Spanish Catalonia has always been an industrial center especially with the city of Ripoll which was a renowned weapons production center since the Middle Ages, and firearms since the seventeenth century. The closeness of the iron deposit of the Canigou mines a few dozen kilometers north in the French Pyrenees must have played a key part in the development of the metallurgical industries in this region. Indeed, since transporting ore over long distances was problematic before the invention of the railway, it was always wise to locate the forges near the places of extraction.

The Spanish Civil War as a context

In the “Comarca” (a Spanish administrative division) of Garrotxa whose capital is the city of Olot (about thirty kilometers from Ripoll) a gunsmith passionate about mechanics named Miguel Corominas y Frigola (1908 – 1977) ran a shop in St Rafael Street. Note that at the time of writing, the mayor of Olot is Josep M. Corominas, a probable descendant of this very gunsmith! Miguel Corominas y Frigola was a character of high stature, silent and austere: the inhabitants of the village called him “San Pau”. He was specialized in bluingSurface finishing of steel giving a black (sometimes bluish)... More and repairs of hunting weapons, and it was quite naturally that he was mobilized – probably in 1937 – in factory no. 15 (Fabrica nr 15). The Catalan government (Republican) had been forced – given the glaring shortage of armaments – to create the Comissió d’Indústries de Guerra (CIG) (TN: War Industries Commission), headed by Josep Tarradellas. This commission was responsible for unifying and above all coordinating the various workshops under the leadership of the powerful metallurgy union (C.N.T.). The idea was to streamline manufacturing. These workshops had been requisitioned and put into management under the regime of collectivization as soon as the nationalist insurrection of July 1936. They manufactured weapons, ammunition and armored vehicles.

The Russian big brother later sold incredible amounts of armament and equipment to the Spanish Republic. Especially when 460.5 tons of fine gold from the stocks of the Spanish central bank in the hand of the Republicans were sent to Moscow! The value of such loot reached $518 million at the time. The sale of this gold began in February 1937 and continued until April 28th, 1938. According to a study by Professor Angel Vina, in exchange for 426 tons of fine gold, the Republican government perceived:

- 245 million of American Dollar

- 42 million of English Pounds

- 375 million of French Francs.

With the currencies thus obtained, the Republican government purchased $132 million worth of war material from the U.S.S.R. The balance was transferred to an account that the Republican Ministry of Finance had opened in a Parisian bank: the “Banque Commerciale pour l’Europe du Nord” (Commercial Bank for Northern Europe). Under Soviet control, this bank made the international payments of the Republic while jealously guarding the hefty sum!

The Factory no. 15

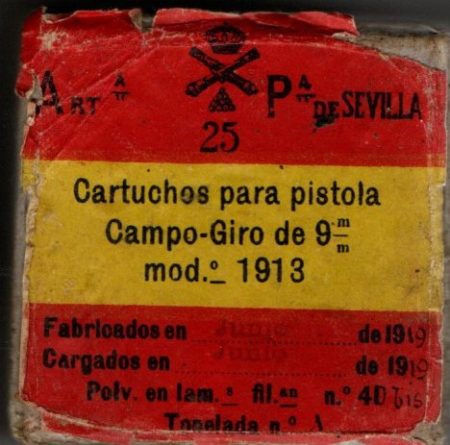

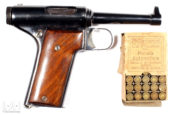

A weapon assembly plant – Fabrica nr 15 (factory no. 15) – was located on Panyo Street. It assembled within its walls the spare parts produced in a multitude of small workshops in Olot and its surroundings. These workshops outsourced manufactured parts for assembling small arms such as the excellent Labora-Fontbernat SMGSubMachine Gun More (in 9×23 Largo – Pic. 3), cartridges and grenades. We also quite easily find (in the dark world of cartridge collectors – or “pyrothécophiles” in French) cartridges of 9×23 Largo stamped “G.C.I.G. nr 15″. This marking thus indicated the production of factory no. 15 from Olot. It stands for “Generalitat de Cataluyia Industrias de Guerra” (Catalogne Government Industry of War).

In the barrel rifling workshop, the examination of the many leftovers too short for use in the manufacture of Labora SMGSubMachine Gun More must have given Corominas the desire to do something with it. The blanks used to manufacture the rifled barrels being of a large diameter to avoid any twisting during machining, the idea of building the receiver directly inside it must have bloomed in the mind of the ingenious gunsmith.

Given the relevance of certain technical solutions used for the manufacture of this very original pistol, it is clear that we are dealing here with a study weapon whose entire constituent parts have not yet been improved. Given the great simplicity of the whole, Corominas’ mastery of the subject is obvious. Because let us not forget that in terms of armament simplicity is an end and not a beginning! The receiver and the barrel are machined out from a raw barrel leftover directly taken out of the rifling bench and then machined. It should be noted that this is also the solution chosen by the Feederle brothers – engineers at Mauser – who invented the C96. The receiver is machined directly by lathing and milling in the barrel blank, which allows optimum cohesion and rigidity and perfect alignment between the bolt and the barrel. This rigid assembly is then cleverly welded onto a magazine well. This last part contains at the back a traditional mechanism including an internal hammer, a safety (blocking the hammer), a trigger and a spring placed vertically behind the magazine housing. This spring pushes both the hammer’s pusher and the magazine’s catch as on a Ruby pistol (Pic. 4). A trigger guard containing the trigger is then brought back to the traditional location as in a conventional weapon.

Following the welding of the barrel / receiver assembly to the magazine well, the weld bead is carefully re-bonded, polished and then hot-blued, which gives the whole a glossy black appearance of the most beautiful aspect. This also enables to detect the trace of the weld, because the particularity of hot-bluing compared to cold-bluing is to take the color in a different way according to the steel grade presented at its junction (Pics. 5 and 6). However, the metal contributing the arc weld does not have the same carbon content as the two welded parts: this results in a difference in color at the junction.

A remarkable feature is also the fact that – unless I am mistaken – this is the first time in history that this method of construction and assembly is used in gunsmithing! All that a few years before the generalization of the use of electric welding as on the STEN SMGSubMachine Gun More. Thus, Corominas was a precursor in the field: the fact of welding the two sub-assemblies with autogenous (with the help of oxyacetylene for example) would have forced the artisan to raise the temperature of the parts to more than 850 degrees which would have had the effect of burning the carbon of the steel to modify the hardness of the metal and to cause a significant veiling of the adjustments during cooling. The use of electric welding avoids overheating, and if the welder masters his technique, allows to obtain a perfect molecular cohesion without bubbles or slag that may generate breaking primers.

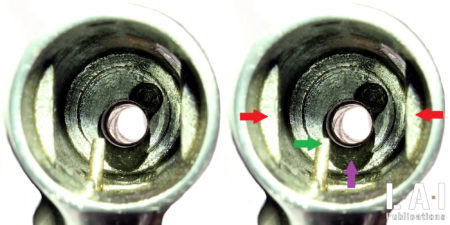

Examination of the weapon

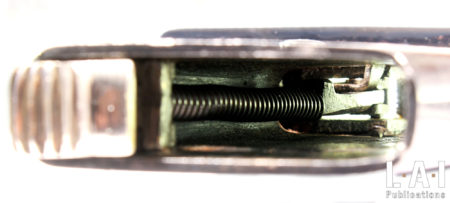

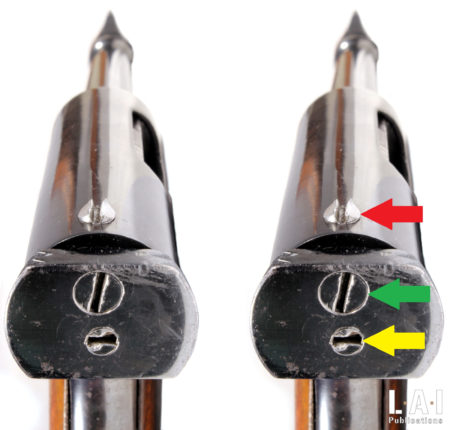

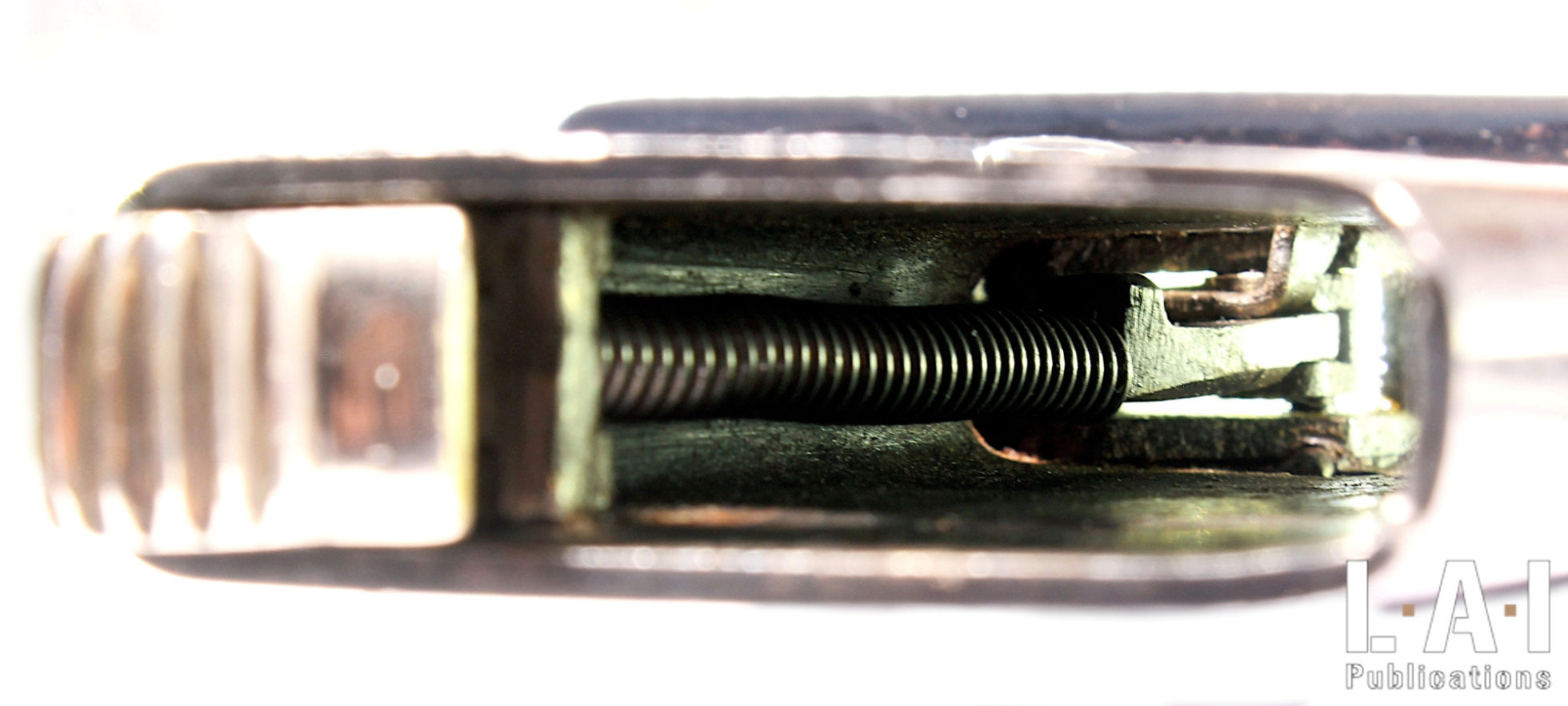

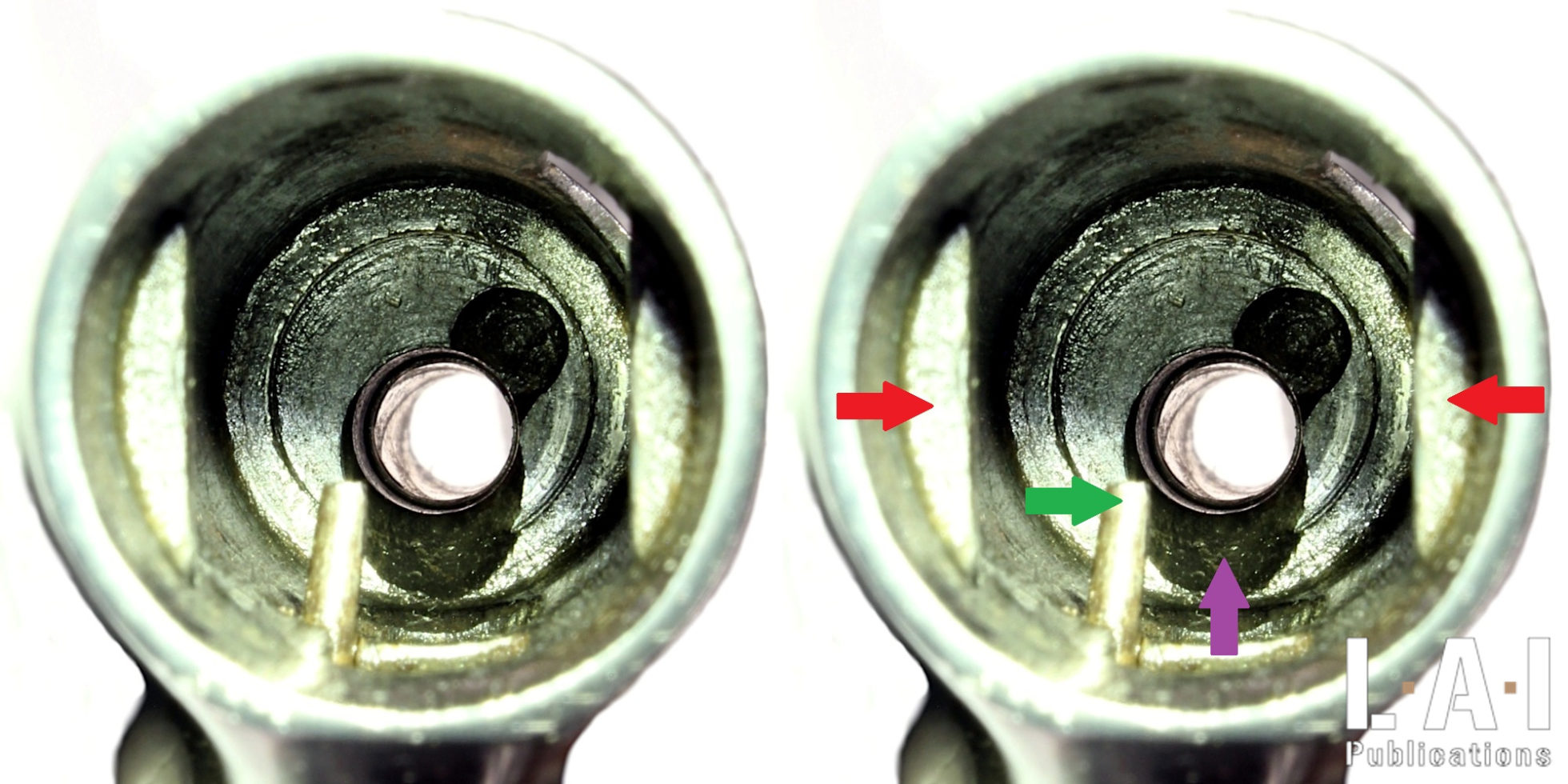

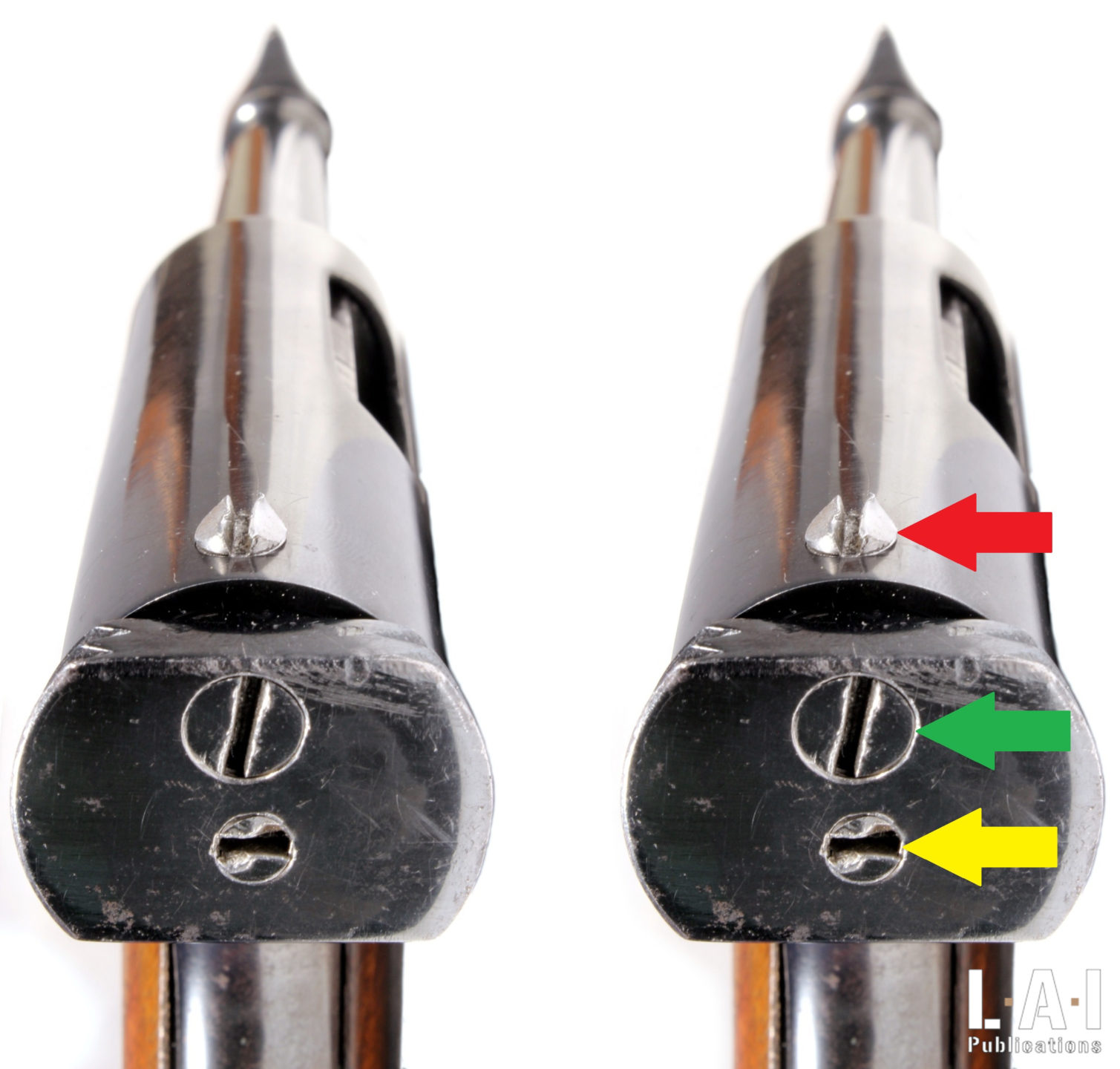

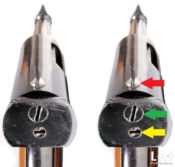

The weapon is therefore made of machined steel, parts of which are assembled by welding. The exterior surfaces were then polished. It is noted that the bolt and the trigger guard are less carefully finished (traces of machining). Some machining is carried out by a succession of drilling and finalized by chisel work (Pic. 7). All these parts were hot-blued after polishing with a polishing machine. The trigger, safety, magazine catch and the magazine itself have a shiny finish. The single-column magazine has a capacity of 8 shots (Pics. 8 and 9). The grips are made of smooth blonde walnut. They are fixed by two flat-head screws mounted without ferrules. The 100 mm length barrel has 4 right-handed grooves. It is noted that both the chamber and freebore are machined with care (Pic. 10). The front sight is machined out from the barrel. We also note that the front sight’s blade has an asymmetrical adjustment that seems to testify to a desire for adjustment (Pic. 11). The notch is made through the screw imprint allowing the assembly of the bolt (Pic. 12). The weapon bears no markings, proof hallmarks nor serial numbers. Its weight is about 900 grams.

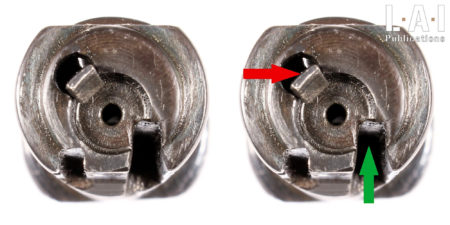

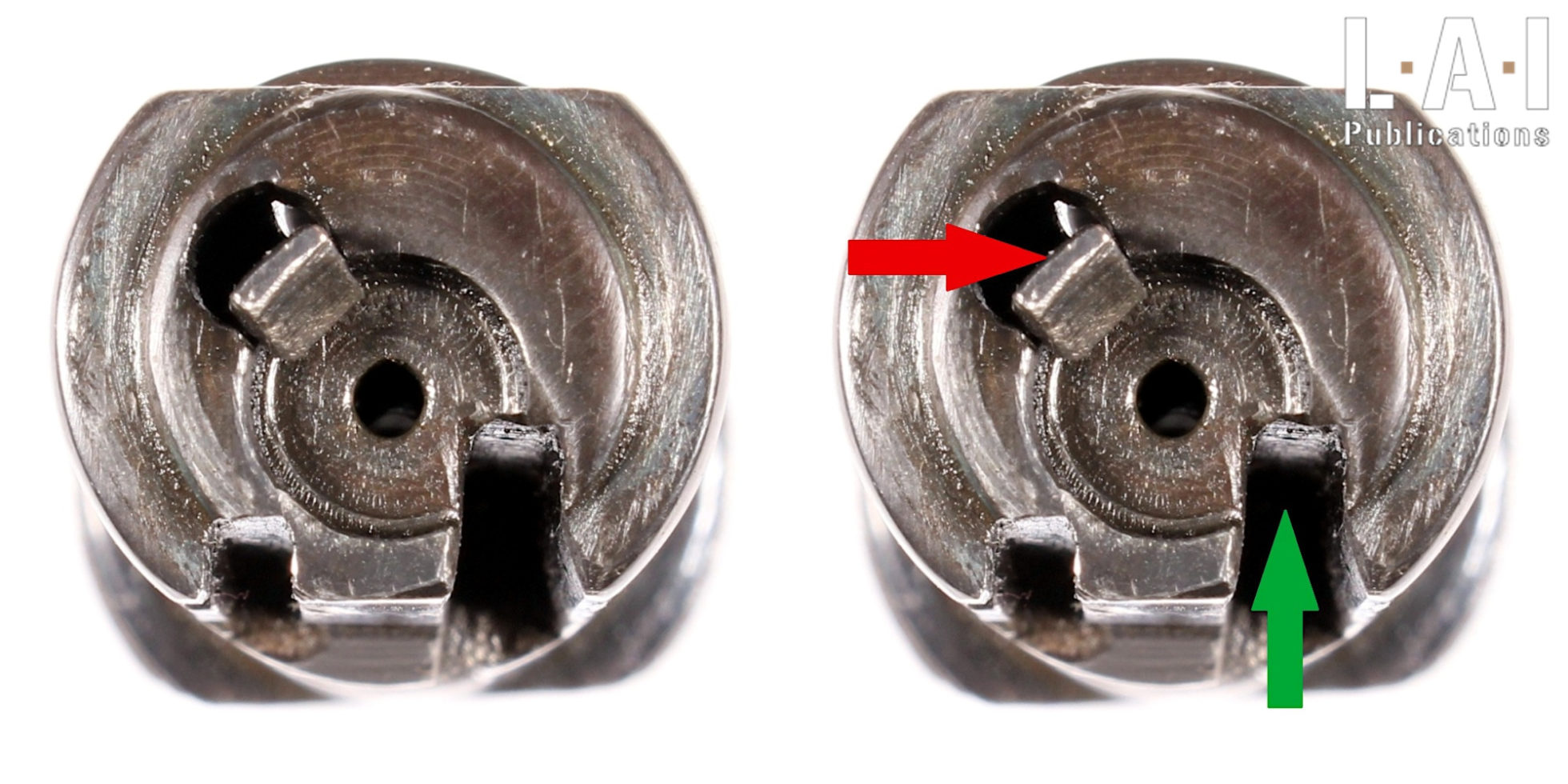

We notice on the bolt two vertical stops that are machined on both sides (Pics. 13 and 14). They limit the stroke of the bolt by stopping on two lugs made in the receiver (Pic. 10). They thus prevent the bolt from being ejected towards the face of the shooter in the event of a problem… such as for example the rupture of the screw allowing the assembly of the bolt and whose dimensions seem very thin compared to the energy involved!

The weapon is straight blowback operated. Thus, the opening delay is ensured by the bolt’s weight but also by the pressure necessary to bring the hammer back into the armed position. This last provision – common on hammer-fired weapons – offers the advantage of multiplying the force of the hammer spring on the first millimeters of displacement of the bolt. Noticeable even when handling this type of weapon, the phenomenon comes from the “reverse leverage” effect! The recoil spring is limited to ensuring a role of damping and specially to move back the bolt forward.

The fixed ejector is mounted on the receiver (Pic. 10 and 15). To generate the semi-automatic shot, the disconnection (action of disconnecting the trigger from the sear) is induced by the lowering of the connecting bar at the end of the trigger stroke. This lowering is achieved by machining a ramp inside the right side of the magazine well (Pics. 16 and 17). Thus, lowered, the bar goes under the sear: it is then necessary to release the trigger to re-initialize the connection necessary to resume the semi-automatic shooting. The separation is therefore independent of the movement of the bolt unlike a large part of semi-automatic handguns: P.08, Colt 1911, C96 … This is very clearly a desire for simplification, as this provision makes it possible to limit the number of parts. On the other hand, some might object here that there is no safety provision avoiding the release of the hammer if the bolt is not in the closed position. This is true, but there is still the safety related to the geometry of the parts of the weapon: if the bolt is not in the closed position and the extractor has not yet engaged its claw into the groove of the case, then the firing pin simply does not have access to the primer of the ammunition!

Cocking is done by gripping the streaks present at the rear. The magazine’s catch is located at the back base of the grip. The weapon carries a small safety lever on the left side of the frame (Pic. 18).

The “field” disassembly is carried out by removing the screw whose head is machined in the form of a circumstantial rear sight notch. The latter is screwed in the receiver, its lower part serving as a support surface for the recoil spring. The lower part of this screw / front sight has a flattened area to index the rear sight (Pic. 19). This indexing is done thanks to the support of the recoil spring. When the screw / rear sight is removed one can remove the bolt: it is still necessary to have it perform a 90° rotation in order to misalign the “safety” lugs of the bolt of the stops made into the receiver. Once the bolt is removed, the two screws present on the back of the bolt can be removed:

- The top screw frees access to the recoil spring.

- The central screw frees access to the firing pin’s housing.

To disassemble the firing pin, it is necessary to unscrew a stop screw present on the right side of the bolt. The blade-type extractor appears to be stopped in its housing by a pin passing through the bolt (Pic. 20). The disassembling of this part was not carried out, for fear of damaging this very rare weapon.

The other elements of the weapon are also assembled by pins. Here too, in order not to damage this weapon – almost unique – we have limited the disassembling to the elements that came out without difficulty.

Shooting test

The presence of copper deposit inside the barrel testifies that the weapon was used and therefore proving that the 9×23 Largo ammunition can be fired in a straight blowback handgun! It is largely the presence of these deposits that prompted me to try this prototype! Keep in mind that the Astra 400 pistols or in their Republican avatars such as the “RE” or “the Ascaso”, are also straight blowback operated. But you really need a strong arm to cock this kind of gun, the strength of the recoil spring positioned around the barrel being really massive. These recoil springs also ensure a very effective damping of the rear movement of the bolt, which is safe. Here, nothing like this, the cocking of the bolt is disconcertingly easy!

During our shooting test, we could see that the grip is good (Pic. 21). The feeding is flawless, the trigger release soft, sharp and pleasant. The ejection is powerful, and the brass are projected to at least 5 meters. The recoil is significant and quite violent. In addition, given the shape of the trigger guard, the index finger is quite violently hit. Finally, since the frame is narrow, the sensation in the hand is not pleasant. The percussion is quite low and on a magazine of 8 shots we still found 5 percussion misfires.

A rare and circumstantial weapon

Despite intense research only three copies seem to be known. A sample has a magazine marked “Fontbernat-Olot”. This is also the only marking that made it possible to guess the Catalan filiation of the pistol! A copy seems to be in the Spanish military museum of La Coruna, without certain identification of the provenance since it is attributed to this arsenal. It should be noted that this copy appears to employ a P.08 magazine.

The weapons of this critical period can be compared to the weapons of necessity that war-torn nations or countries embargoed by an adversary of superior force have always managed to manufacture by developing ingenious and inexpensive solutions. We can thus think of the arms manufactured by the Southern states during the American Civil War, those produced by the French Government of National Defense in 1871 to drive the Prussians back, those of the Volkssturm developed by a Nazi Germany in dire straits and of course the weapons produced in Catalonia during the Spanish Civil War, an example of which has just been presented to you here!

Gil Sigro y Peyrousère

Thanks to Jean-Pierre Bastié for his help in identifying the weapon.

For ammunition details:

https://municion.org/producto/9-x-23-bergmann-bayard-largo/

Bibliography:

- PISTOLA CALIBRE 9 mm. Largo., PROYECTO DE LAS INDUSTRIAS DE GUERRA DE CATALUÑA (¿?) Juan L. Calvó Enero, 2009

- La industria de guerra a Catalunya (1936-1939) l’obra de la comissio creada per la generalitat, i el seu report d’actuasio. Pages editors.

- Tarradellas y la industria de guerra de catalana (1936/1939) Javier de Madariaga. Edition Milenio.

- ASTRA Automatic Pistols, Leonardo M. Antaris, Colorado USA, 1990.

- STAR Firearms, Leonardo M. Antaris, Davenport USA, 2001. “La Industria Armera Nacional, 1830.1940. Fábricas, Privilegios.

- Patentes y Marcas”, Juan L. Calvó, Eibar, 1997 “Revólveres y pistolas en las FF.AA. Españolas, 1855-1955”, Juan L. Calvó, Barcelona,

- PISTOLAS Y SUBFUSILES DE LA REPÚBLICA. PRODUCCIÓN DE GUERRA. Josep Mª Abad, Manuel Estirado y Francisco Fuentes .

- Los autores, 2013 ISBN 8461666720 9788461666720

- www.municion.org

Personal collection.