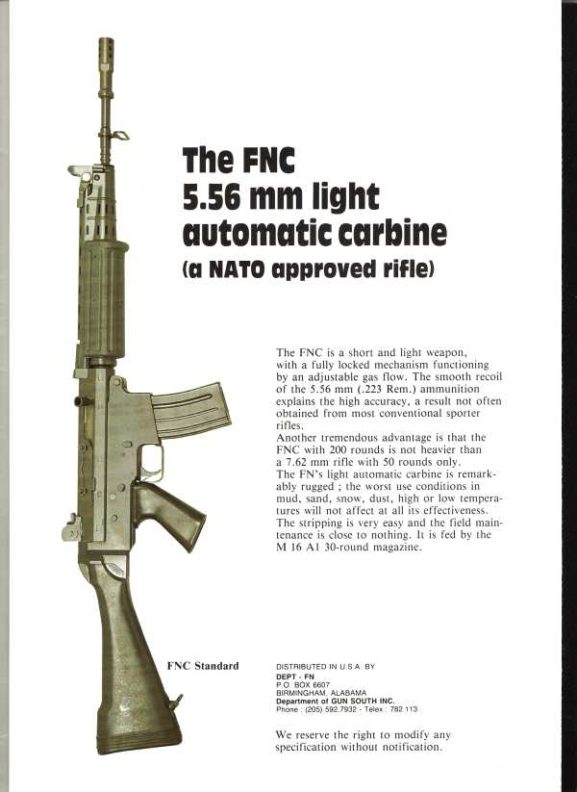

FNC-80: a Kalashnikov for the West?

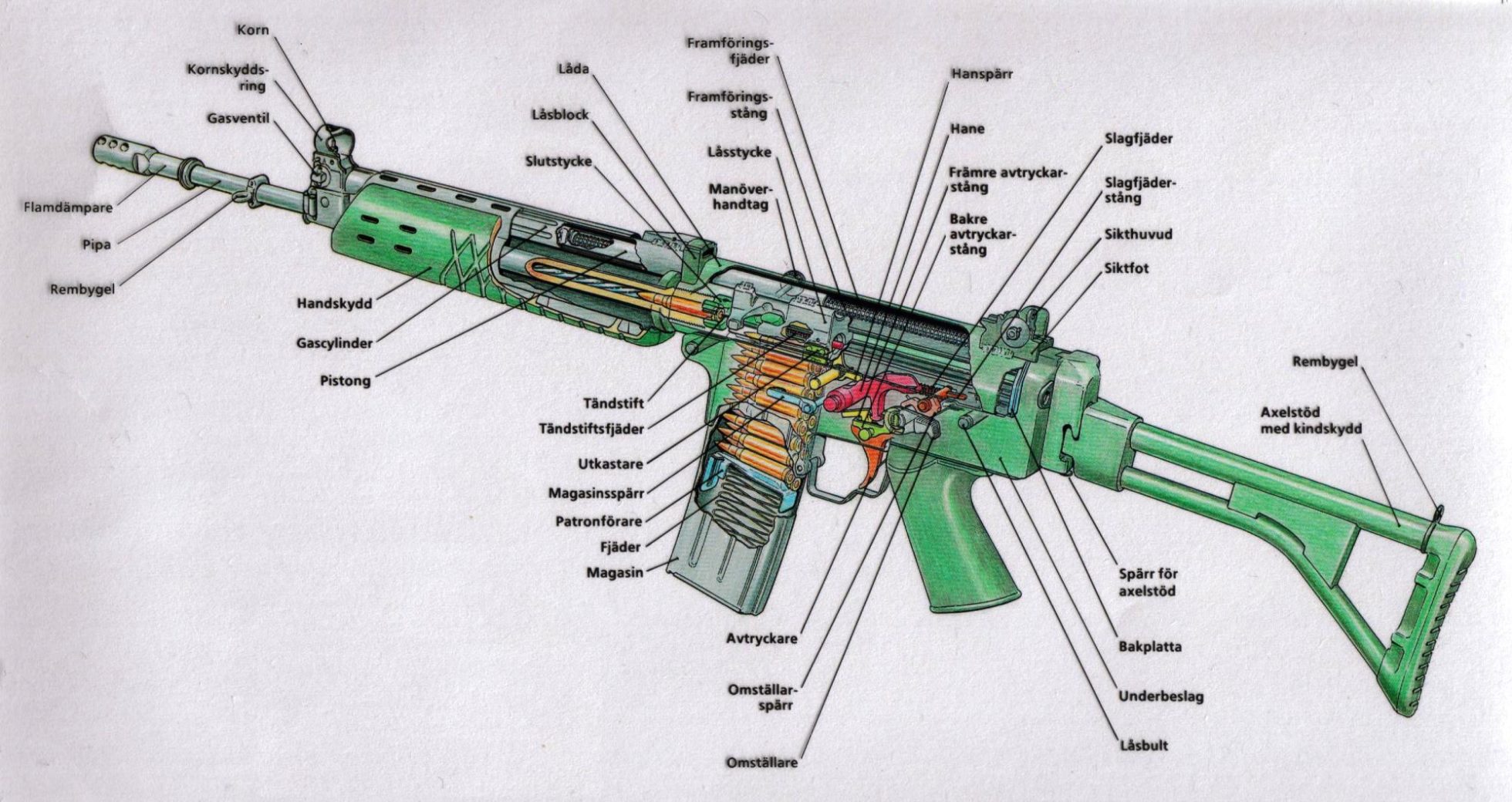

In 1967, the Fabrique Nationale de Herstal, Belgium, presented the “Carabine Automatique Légère” (Light Automatic Carbine) or CAL in caliber 5,56×45. Often wrongly presented as a derivative of the FAL, this weapon designed under the direction of Ernest Vervier, is actually very different. Produced since 1970, it massively used stamped sheet metal for its construction, a rotating bolt and a piston attached to the bolt carrier at the time of firing. The design of these lugs is also reminiscent of that of the hunting rifle “Browning Bar”. It offered accessories then uncommon on the European arms markets such as a limited burst of 3 shots and the possibility of mounting an auxiliary grenade launcher of 40×46 mm. Initially expected to be inexpensive in production and reliable, this weapon was abandoned in 1977 because it did not reach the desired goals.

At the beginning of the 1970s, this weapon had already been tried for a long time by the French authorities who desired to adopt a weapon in 5.56 caliber. These tests demonstrated several problems, including a field disassembling considered particularly laborious for military use. These reflections would constitute many different paths for the development of the next rifle that we will study through this article: the FNC-80.

A worthy anecdote, it is frequently accepted that the FN CAL or a modified version of the CAL would have been the assault rifleAn assault rifle is a weapon defined by the use of an "inter... More of the French army if Belgium had bought Dassault Mirages fighter instead of American General Dynamics F16s. This anecdote allows us to consider of the fact that some decisions are made on other levels…

Genesis

In 1975, the FN’s Research and Development Department led by Maurice Bourlet launched the development of a new 5.56 caliber assault rifleAn assault rifle is a weapon defined by the use of an "inter... More. Mr. Bourlet assembled a team of young engineers led by André Dubru who, drawing on the feedback from the CAL’s French experience, proposed a new prototype at the end of the same year. It will be baptized FNC-76 for “Fabrique Nationale Carabine” 1976. This weapon, different from the CAL, nevertheless takes several elements such as a large part of the trigger mechanism (including the burst of 3 shots) or the design of the handguard.

Just like its Soviet “Kalashnikovians” cousins, this new rifle was designed with simplicity in mind. Let us take a small digression to recall that at the heart of Soviet simplicity, the design and evolution of Kalashnikov’s weapons responded to two lines of research: rationalization of the production of the weapon and increase in its maneuverability, including shooting control. These two lines explain the entire evolution of the AK-47 into AKM and then into AK-74, at levels of detail truly exceptional in the world of weapons. Regarding the FNC-80, we are talking about the simplicity of disassembling and assembling, maintenance and especially production. The simplicity of production was to be considered in the light of the capacities and industrial realities of the manufacturing country. This included the cost of labor, the level of industrialization, access to raw materials… In any case, it was necessary to achieve this goal to design parts that were simple and quick to mass produce by means of tools that did not require a highly skilled workforce. This production also had to be economical in raw material, production being done on a large scale. Stamped sheet metal and synthetic materials were an obvious first axis of development at the time of the design of the weapon. However, the use of Computer Numerical Control (CNC) machines and robots for manufacturing or assembly (welding in particular) spread at the same time and would thus be widely used to produce the weapon. Similarly, the use of aluminum for weapons construction can also be seen in this aspect, aluminum being cheaper and faster to work with than steel. Finally, the use of heat and thermochemical treatment of metals would complete the production panoply, in order to guarantee the appropriate technical properties for the elements of the weapon without resorting to very expensive “competition” steels.

Prototypes would be tested by Sweden from October 1975, for possible adoption, and by NATO from January 1977 for evaluation. A series of modifications would be applied in 1978 and 1979 to lead to a “definitive” version: the FNC-80.

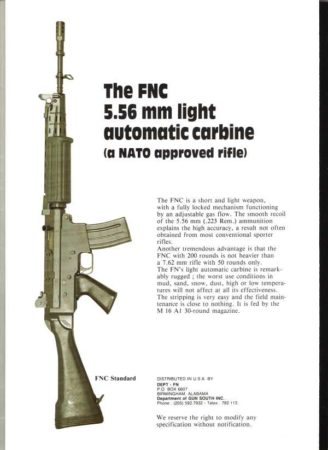

Although the weapon was designed around the Belgian SS-109 ammunition, it was proposed with both types of barrels: at a twist rate of 1:178 mm (1:7″) for the SS-109 and at 1:305 mm (1:12″) for the American M193. We do not know if any weapons with the 1:305 mm twist rate barrel were really produced. In any case, these barrels have 6 grooves on the right and their bore and chamber are chrome lined. The weapon was offered in several variations: synthetic fixed stock, folding stock identical to that of the FAL PARA, standard barrel of 449 mm, “Para” version with barrel of 363 mm, semi-automatic version … Here, as often, the customer is king, and therefore it is possible to obtain many configurations.

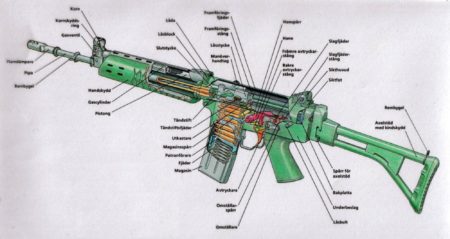

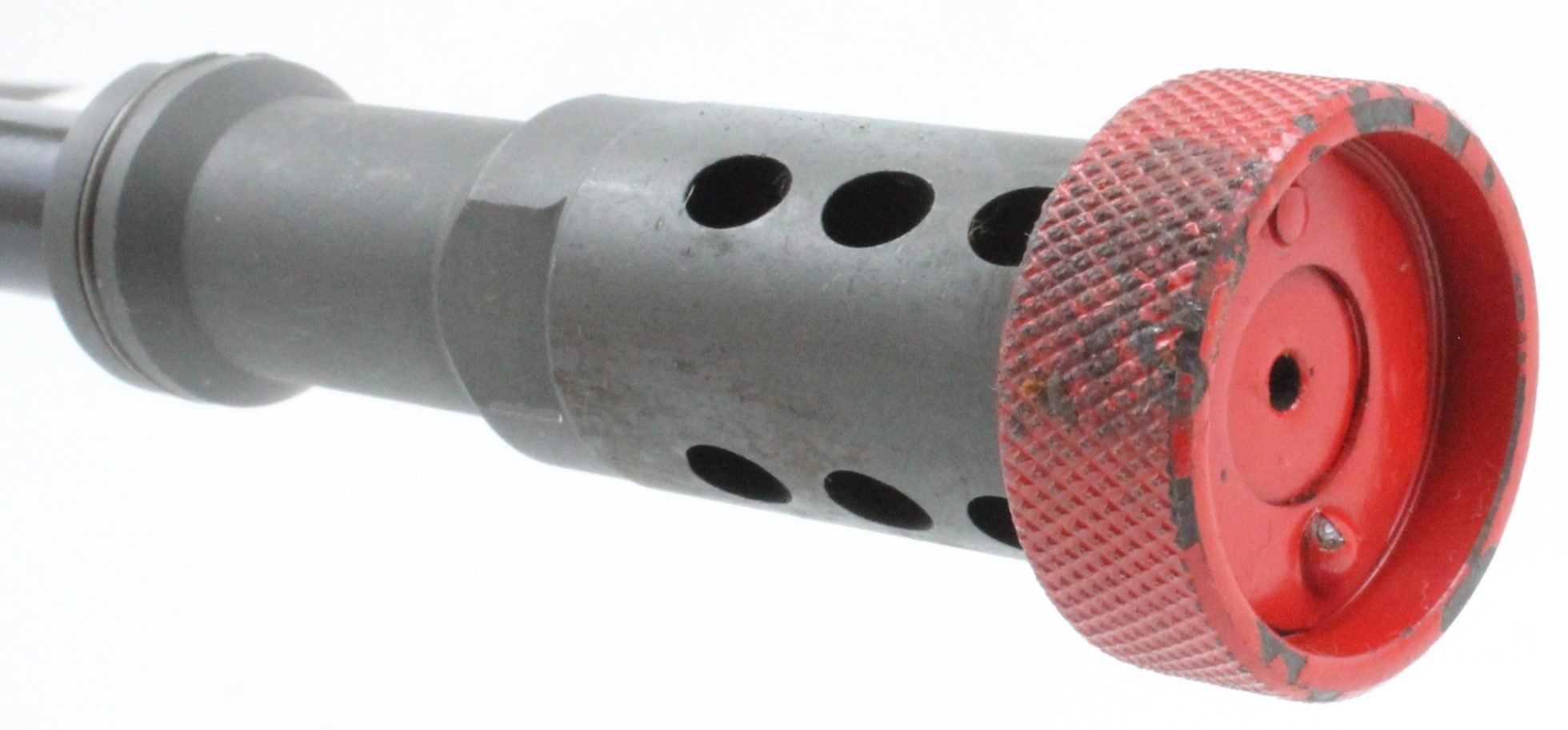

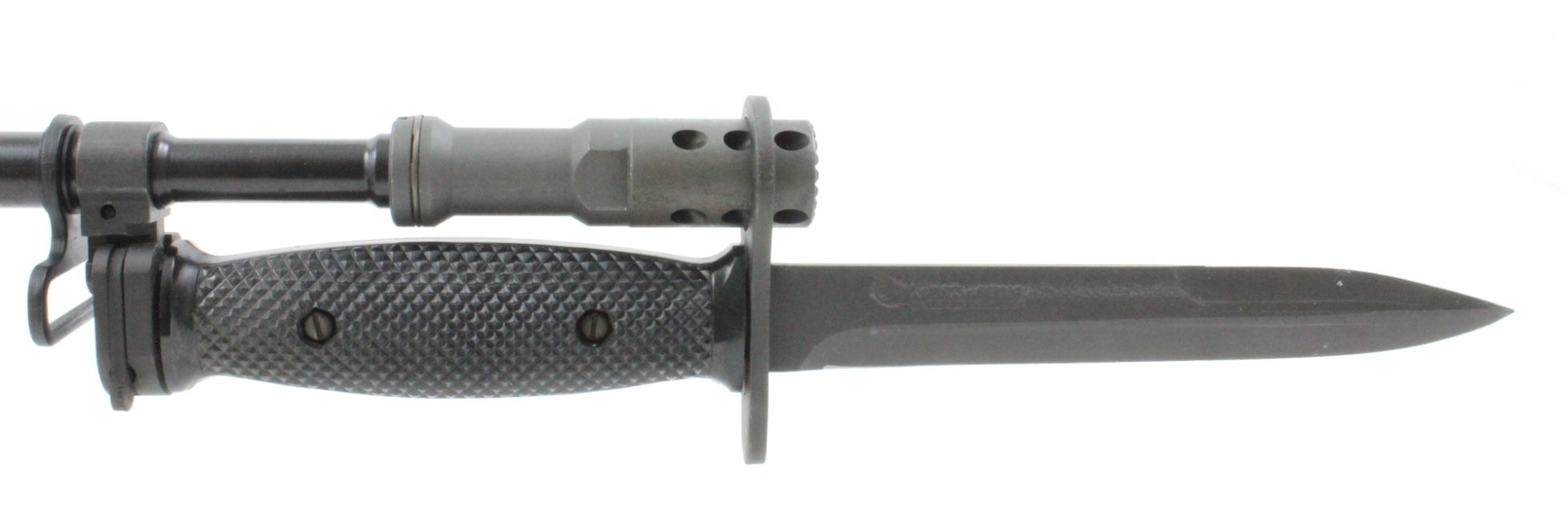

The accessories offered with the weapon by the FN are classic and largely derived from those of the FAL. The pistol grip has in its housing a cleaning kit similar to those existing on the FAL. The blank-firing adapter is identical in design to that of late FAL: it uses the internal thread of the flash suppressor and brakes on the serrated knurling located at the end of it. The weapon originally used the type C bayonet of the FAL with hollow handle. Our copy allows the mount of two different types of bayonets: the FAL type C and the M16. It is possible to mount a bipod clamp directly on the barrel. The weapon has a quick mounting system for optics that hooks to the front of the upper receiver and locks on the base of the rear sight. The optics originally proposed is derived from the Hensoldt 4×24 found on the G3 but produced by OIP in Belgium. The original assembly is to the “STANAG” standard and therefore allows the mounting of any optical or optronic to this standard. And why not a very French optronics such as the OB-50!

On the road to adoption

The first major order for FNC-80 (10,000 weapons) would be made by Indonesia in September 1980, at the same time as the FN completed the establishment of the production line. The Indonesian manufacturer Pindad would acquire the production license in 1984 to manufacture the SS1 (Senapan Serbu 1 or Assault RifleAn assault rifle is a weapon defined by the use of an "inter... More 1). The weapon was officially adopted by the Indonesian Army in 1991. It is still in service, when we write these lines. Indonesian manufacturing is very similar to Belgian manufacturing in that it allows the mounting of the grenade launcher also manufactured by Pindad, the SPG-1, derived from the American M203.

Sweden followed suit in 1984 with the order of 80,000 weapons, with a slightly modified design, named Automat Karbin 5 or AK-5… curious coincidence. The modifications include the replacement of the front sight ears protection by a hood, a handguard and a cocking handle with a different design and the elimination of the 3-shot burst. The delivery of weapons from Belgium would soon give way to Swedish production under license at the Forenade Fabrikverken (FFV) in Eskiltuna. Note here that in the duel at the top of the selection, this choice was made to the detriment of a Kalashnikov system: a locally modified version of the IMI Galil.

Belgium, for its part, would not order this new weapon until mid-1986. The FNC would be in the process of replacement by the FN SCAR L at the time of writing. The FN F2000 was acquired only in limited quantities for the need of the special forces.

Arriving a little late on the world market of small arms in 5.56 of first generation (that of the Cold War), it would still meet a certain success in export. However, it could not match the planetary success of its ancestor, the FAL.

Ergonomics resolutely for war

A cocking handle on the right, a selector on the left, M16-style magazine release (one of the few flaws he inherited from his American counterpart) … nothing new. The weapon does not have a bolt catch at the end of the magazine: this is a good sign. Indeed, a bolt catch does not bring anything in situation (even if some believe the opposite …), except the risk of seeing its weapon fill with foreign bodies at the end of the magazine or the risk of seeing the bolt remain stuck at the rear in case of failure of the device. In general, the more devices there are within the weapon, the more likely it is to fail. The situation on older weapons must be seen from another angle: when using En Bloc or stripper clipDevice containing ammunition and intended to supply a weapon... More for loading, it is necessary to block the breeching mechanisms at the rear during the loading phases. As soon as the use of the clip is abandoned (at least for direct loading of the weapon), it is fashionable to remove this unnecessary and potentially dangerous appendix. This is the mark of the great weapons of war: Stg-44, Kalashnikov, G3, Famas… Note here that the first versions of the FAL provided for the use of stripper clipDevice containing ammunition and intended to supply a weapon... More, so it is consistent that the weapon is equipped with it. Even the F2000 is devoid of them. The G36, on the other hand, gives you the choice to activate or deactivate it! As for the HK-416 and HK-417 and other FN SCAR L and H, it is necessary to understand here that these weapons were designed according to specifications that required the presence of such a device. Therefore, the question must be: was this specification well thought out? From our point of view, this is not the case. But this is a matter of our personal appreciation: to be fully honest, we had to affirm here our thoughts on the matter. However, we do not claim here to be the holders of a universal truth: everyone can form an opinion.

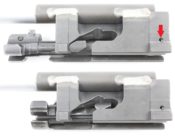

If the weapon is not equipped with a bolt catch at the end of the magazine, it is however possible to intentionally block the bolt carrier group at the rear as on a G3 or derivative. To do this, bolt carrier group at the rear, it is necessary to pull the cocking handle outwards so that it engages in the recess provided for this purpose in the upper receiver. The maneuver is not as instinctive as on a G3 but has the merit of existing. It should be noted that this is an operation that is carried out only for inspection or safety purposes and is therefore not carried out under stress conditions.

In the same concern for reliability inherent in the introduction of foreign elements within the weapon, the path of the cocking handle is sealed by a plastic dust cover powered by a spring, and which faithfully follows the passage of said handle to maintain an optimal seal. Its action is remarkable filmed in slow motion as you can see in the movie at the end of this article.

The selector is directly inherited from the FAL and its design is perfectly suited to the use of an assault rifleAn assault rifle is a weapon defined by the use of an "inter... More. The most used modes are easily accessible at the rear (safety / semi-automatic) and the burst and automatic modes, at the front, require an extra effort to be accessible. This avoids the pitfall of “skipping” a mode when releasing security. This provision seems to us to be as valid as that of the Kalashnikov rifles which had arranged the two preponderant functions in upper (safety) and lower (semi-automatic) ends. In combat conditions, the soldier “crushes” the selector in the desired position. There is no doubt that the staging of the selector is thought out. However, it should be noted that this provision has not been retained for the Swedish AK-5, whose selector has the 3 positions on the rear.

It should also be noted that the predominant mode of use of the assault rifleAn assault rifle is a weapon defined by the use of an "inter... More is not the burst, but the blow by blow, which makes it possible to deliver a better control of its “firepower” with better adjusted shots. The term “assault rifle”, derived from Nazi propaganda “Sturmgewehr” term, is also very inconsistent with the actual use of the weapon. The “assault” phase (and therefore the automatic modes) represents only an occasional situation of the use of the weapon. It would be more of the “battle rifle of the last 300 / 400 meters” (Thank you Pierre BREUVART for this “Copyright”!).

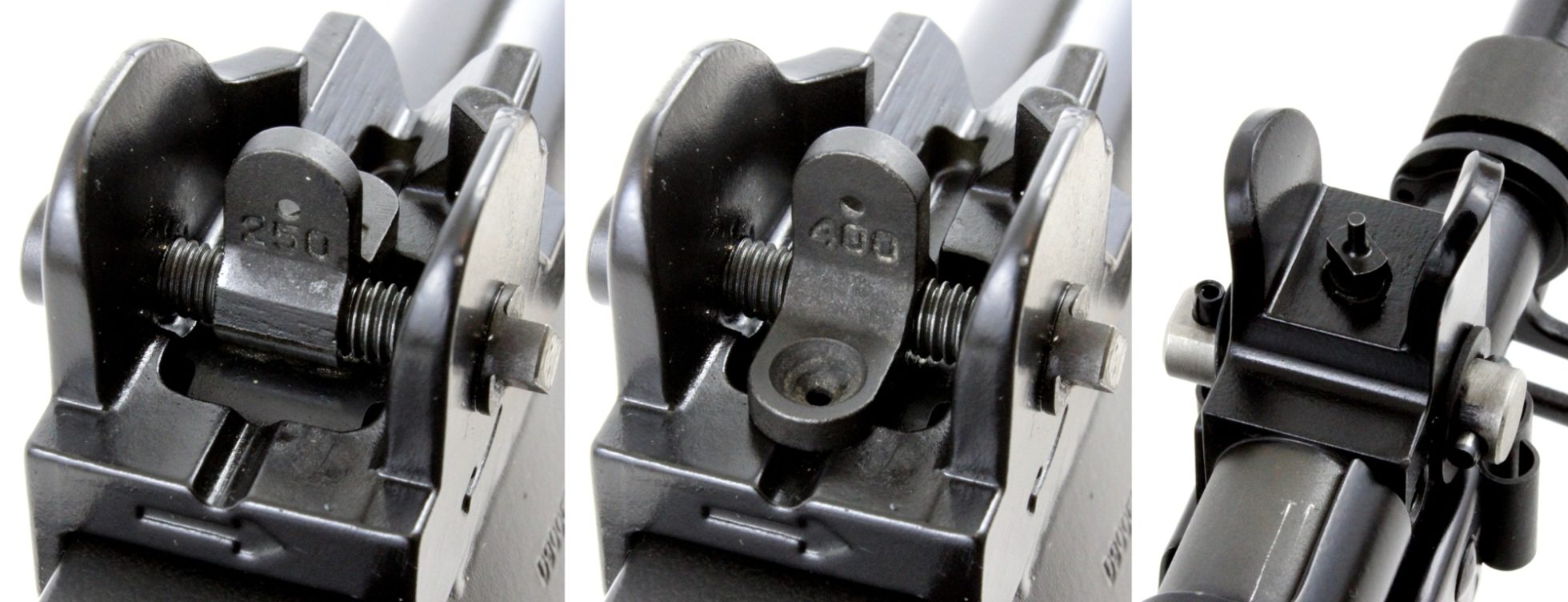

The iron sight is of the apertures type. The rear sight is of L-type flipped and is designed for the 250 and 400 m ranges. The front sight is not under a hood but protected by two very properly proportioned ears. The elevation adjustment is provided by the screwing / unscrewing of the post, and the windage by action of the support screw of the aperture. We will note here that the adjustment is provided by the same tool for the elevation and the windage and that the tool allowing the elevation adjustment of the Kalashnikov’s post is perfectly adapted …for its shape is identical! The sight distances are adequate for combat firing with 5.56 (center-hold sight of a military target) caliber and almost fit the distances of the iron sight of the M16 and M16A1 (250 and 375 m). A positive point for interoperability issues within NATO, at a time when the M16A2 (whose iron sight is too complex for military use from our point of view) is not yet adopted.

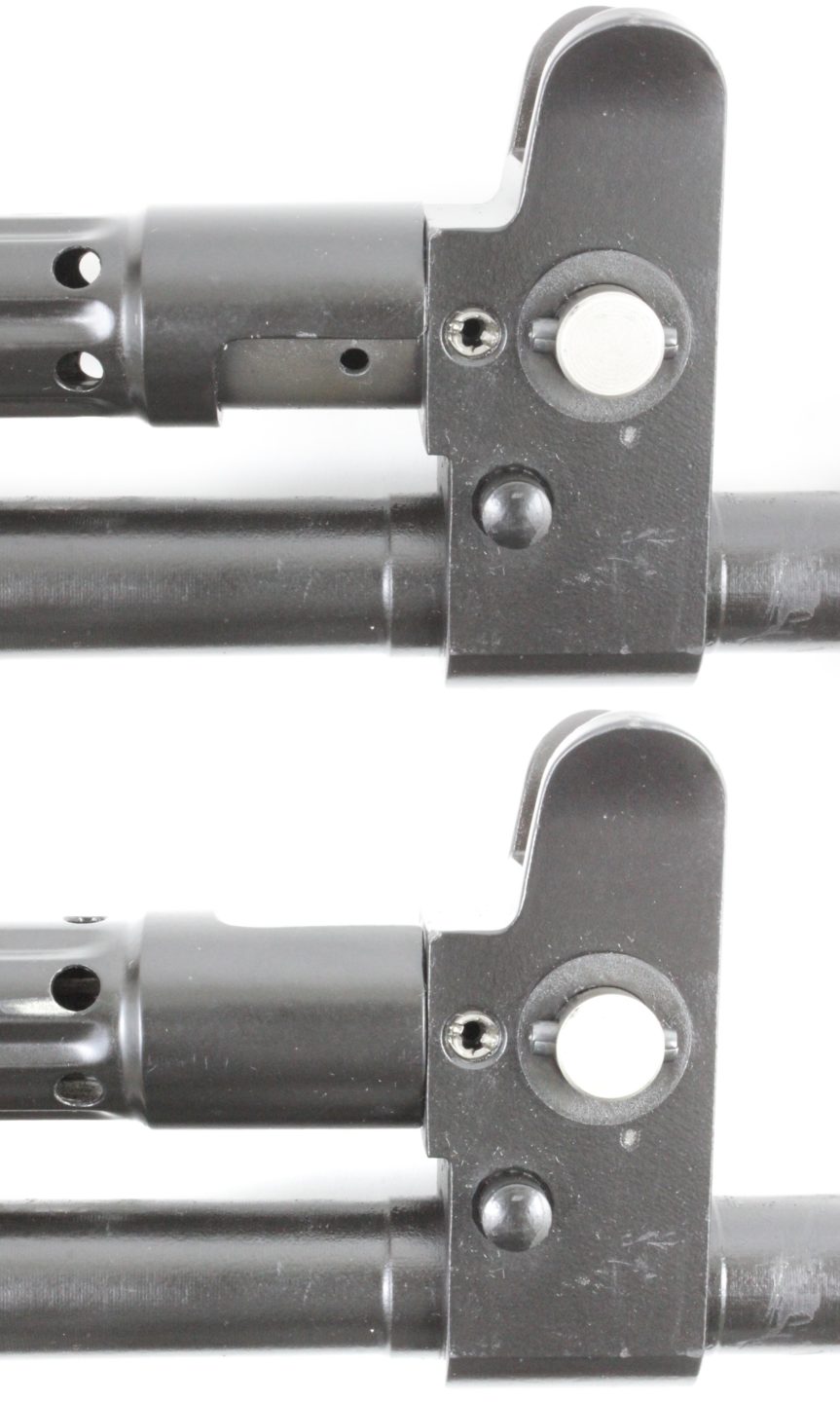

The weapon is equipped with a gas regulator in two positions: “normal” and “harsh” condition. The notion of “harsh” refers here to harsh environmental conditions: sand, mud, polar cold, etc. Its drawing exudes the rather negative feedback of the FAL regulator. Which FAL user hasn’t pulled their hair out trying to adjust a dirty (or rusty) regulator knob! The regulator works on an identical principle: it drives-out a quantity of useless gas by a vent present on the gas block in “normal” mode and keeps it for a stronger thrust in “harsh” mode. But unlike the FAL, its large handle allows for the easiest implementation, even with gloves. The location of its maneuvering part is both close to the shooter (it is not necessary to unshoulder the weapon) but also designed to be operated even when the barrel of the weapon is burning hot. Its disassembling and cleaning are easy.

The weapon can fire rifle grenades with empennage of 22 mm internal diameter via its flash suppressor inherited from the latest FAL productions. For this purpose, it has a gas cut-off valve on the gas block. This valve also officiates as a sight for grenade. This sight is absent from our test sample, certainly because the original customer of this production – probably the American administration in view of the markings – did not want it. However, the valve is still present even if not operational. Perhaps it is in a spirit of production rationalization, but perhaps also that cut-off valves make possible to adjust the operating cycle of the weapon in the factory. We know other weapons where this is the case.

A bit of technics…

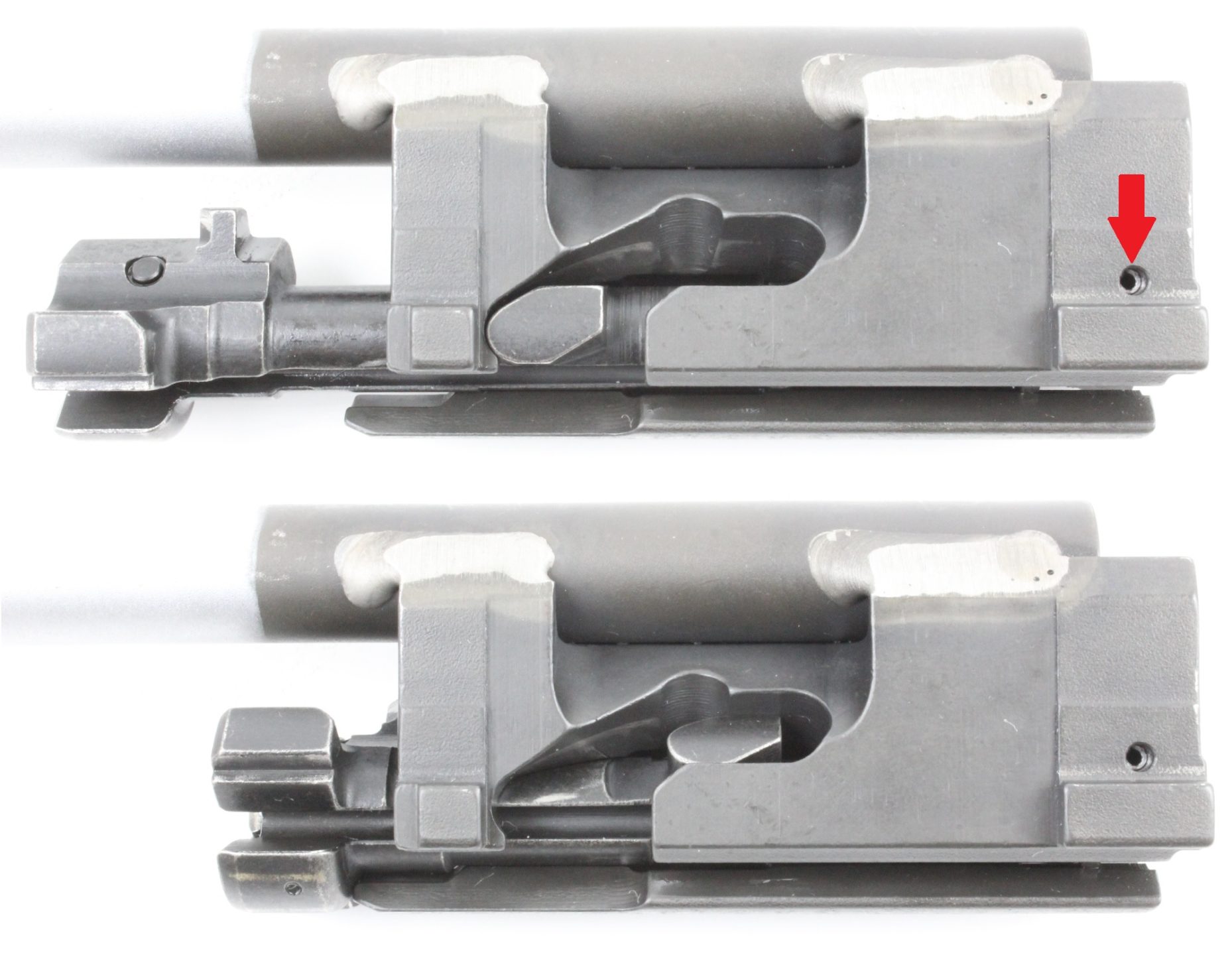

The weapon is built, like the FAL, around a lower receiver and an upper receiver. The two receivers are assembled via two pins that remain captive to the lower receiver at disassembly. The lower receiver is made of forged / machined aluminum. It houses the magazine well, the trigger mechanisms and the stock. The upper receiver, made of stamped sheet metal, accommodates the barrel locking extension (welded to the receiver) on which the barrel is screwed. The ejection port is cut out on the right side and is reinforced by a steel welded brass deflector on the upper rear part. The bolt carrier group circulates inside this upper receiver on two guide rails welded on either side of the receiver. The recoil spring, positioned from the rear, is contained as on the AK-47 and derived inside the bolt group carrier. Like the Kalashnikov mechanics, it seems that particular care has been taken to leave room for the parts to move despite a strong fouling.

The elements of the weapon are phosphated (when they are made of steel) and painted for a major part of the external elements. The piston, like the barrel, is chrome plated.

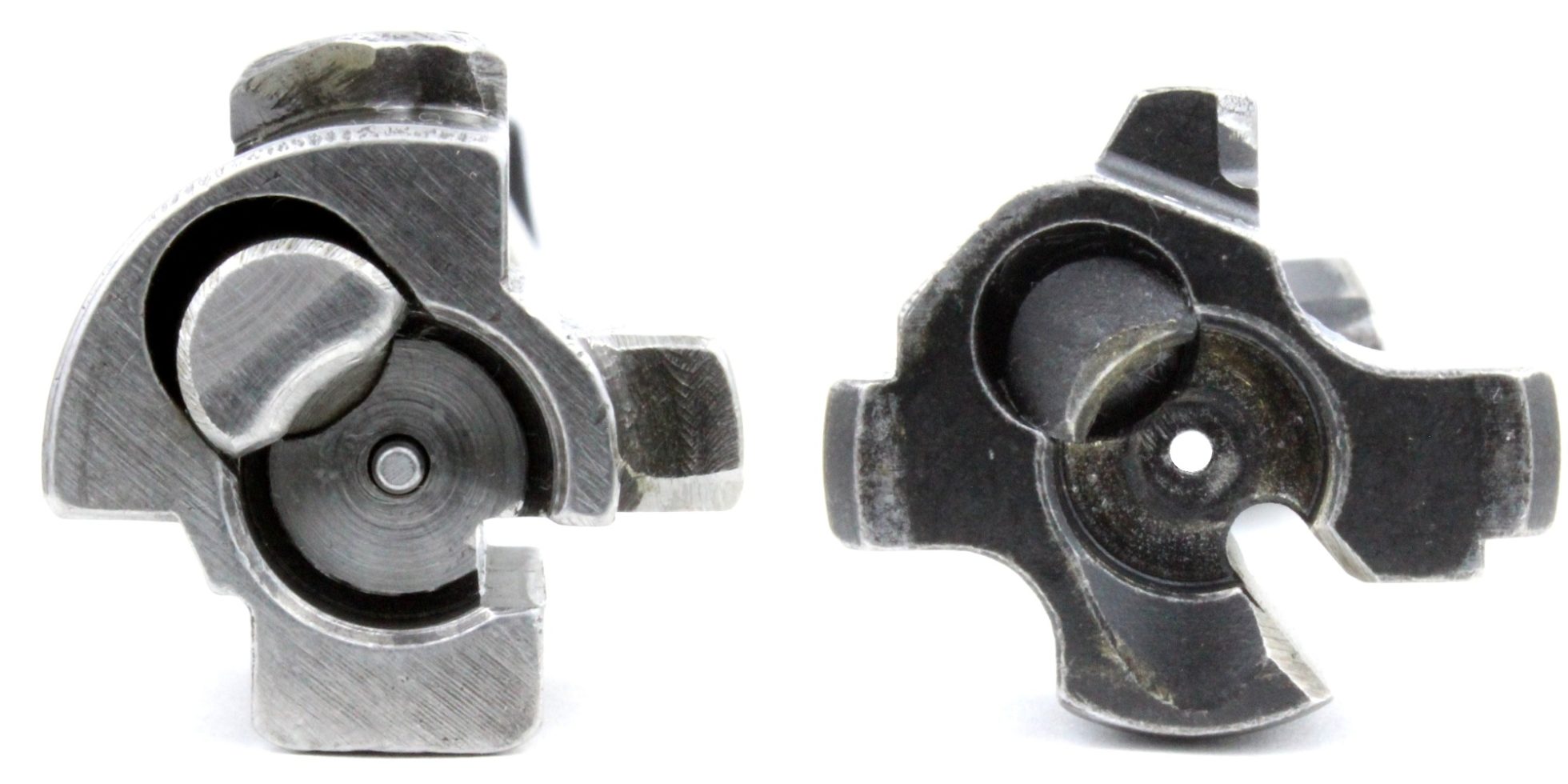

The weapon operates from a long stroke gas system with rotating bolt with two lugs. When the bullet passes in front of the gas port of the barrel, the piston of the bolt carrier group is impulsed by the pressure of the gases. On the inertia of this impulse and after departure of the bullet from the barrel, the bolt carrier unlocks the bolt and generates all the operations necessary for rearmament. On this point, it has obvious similarities with its Soviet cousin. Some will talk about copying, for our part, we will talk about adaptation, which is very different from a simple copy. If the similarity of the design of the bolt is obvious, the rest of the design of the bolt carrier group is still modified to adapt the weapon to production needs or new choices of gunsmithing technique. In the radius of similarities note that the mass of the bolt carrier group of the two weapons is almost identical (about 500 grams), which should not be considered trivial. Indeed, the mass of the bolt carrier group is a major variable for the proper functioning of a self-loading weapon. The more mass there is, the more reliable it is.

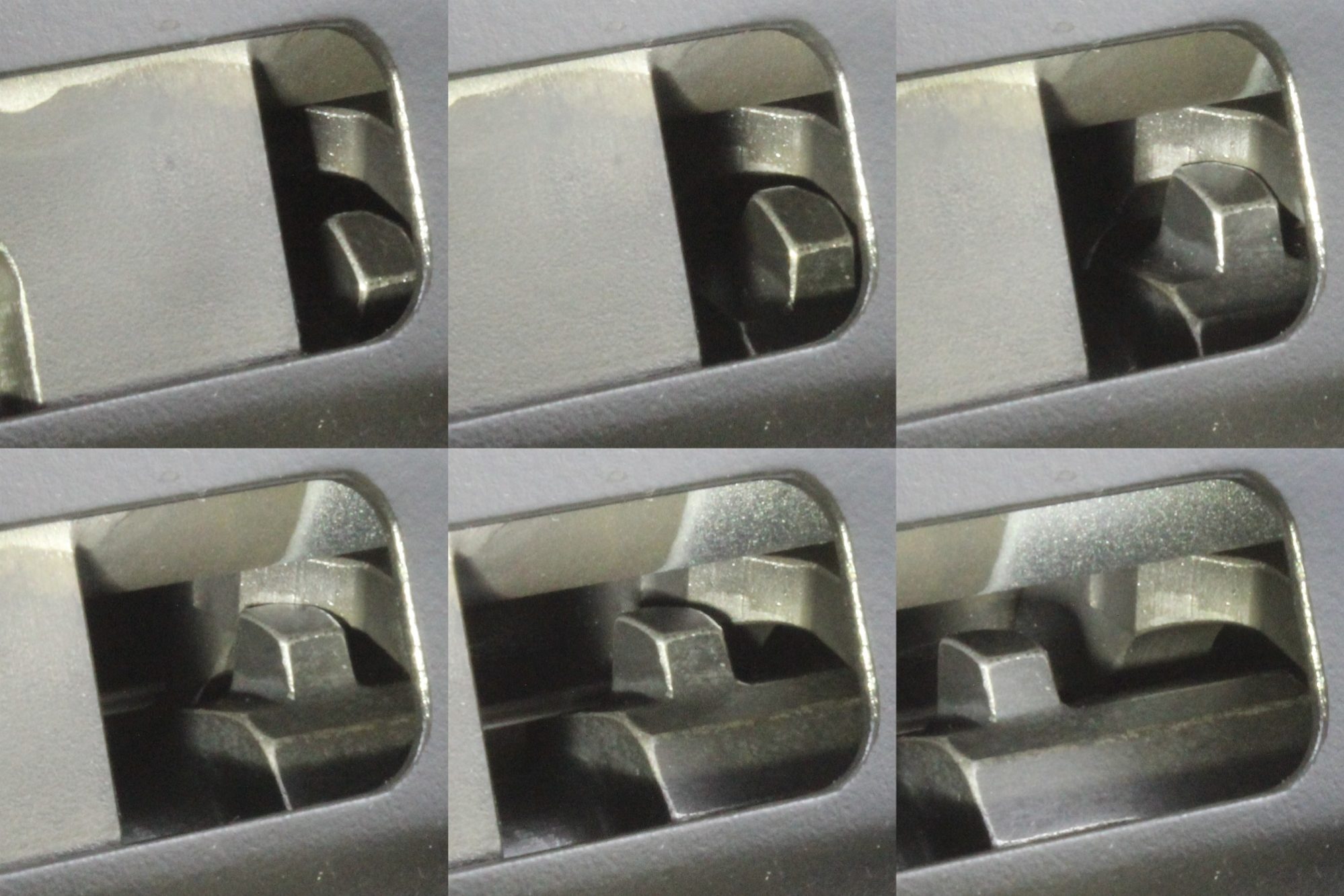

Like Kalashnikov systems, the weapon has a primary extraction. Primary extraction is an action that combines a rotational movement with a rear translation of the bolt to facilitate the peel off and extraction of the pulled case. Here, this arrangement is produced by the sliding of a lug placed at the top of the bolt on the locking extension of the barrel. After the end of the unlocking, the bolt continues its rotation and therefore begins its rear translation, not under the action of the rear movement of the bolt carrier group but following its sliding in rotation on a slope of the barrel extension. The extraction action is therefore less brutal and more effective because of a helical movement. This provision is rather rare on western assault rifles. Its presence here is perhaps due to the negative feedback of the Americans with the M16 and M16A1 in Vietnam, where cases stuck to chambers and other rim shears were extensively recorded and documented. It may also be that the use of lacquered steel cases was also considered. Finally, it could be derived only from the “copy /paste” of the Soviet weapon. We will note that at the eternal competitor from across the Rhine, the chambers of most shoulder weapons since the production of the G3 were “fluted” to avoid the sticking of the cases. For memory, the grooves in the chamber provide lubrication of the cases by adduction of hot temperature carbon at the time of firing. Contrary to what is often believed, the purpose of the fluted is not a mechanical action of the gases on the case. We find this provision on the G3, HK-33, MP-5, AA-52, AN-F1, FAMAS… which are all operated from delayed blowback. Note that on these weapons, the absence of rotary movement of the bolt in the axis of the barrel prohibits the integration of a primary extraction. On some productions of HK-416 and HK-417, whose locking and extraction are partly derived from the AR-15, there can be fluted chambers (at the request of customers, for example, the French Army) for fear of sticking case …

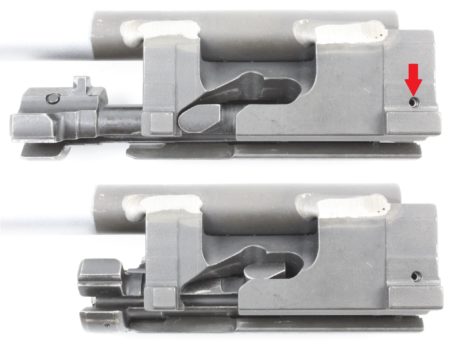

A major difference of the FNC-80 with the Soviet cousin is that the firing pin is worn on the FNC by the bolt carrier group (as on an AR-15) and not by the bolt itself. This difference brings two benefits to the credit of the FNC. In the first place, in a safe way, the firing pin can only protrude into the bolt faceThe bolt face is the part of the bolt which in set place the... More if the bolt is fully telescoped in the bolt carrier. This involves locking within the weapon, so that no firing if the bolt is “out of battery” is possible. In the second place, it enables to operate a mechanical removal of the firing pin when opening the mechanisms, which is always better mechanically to avoid nailing (certainly almost non-existent on contemporary war small arms). The Kalashnikov system also has a safety device preventing firing if the bolt is not fully closed, but this intervenes on the hammer and not on the firing pin, which may seem less secure.

It can also be noted that the piston consists of a tube of which only the head, reported by welding, is machined. An efficient simplification of production compared to the Soviet model.

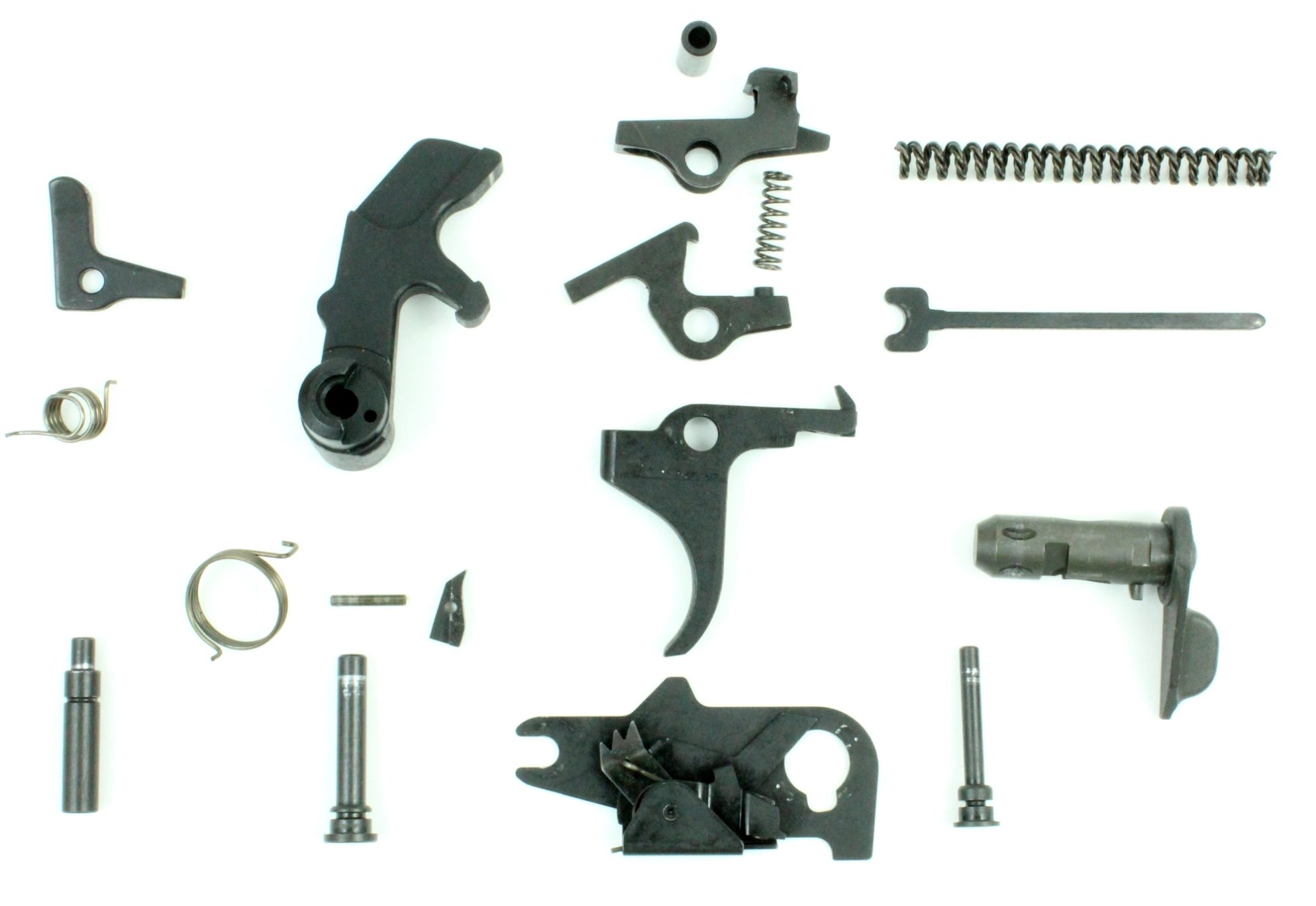

Mechanically, the firing system is relatively conventional: we find, “one” main sear (i.e. the one that operated by the finger of the shooter), a disconnector to create the semi-automatic mode and an automatic sear controlled by the forward movement of the bolt carrier group. The automatic sear is inherently a safety prohibiting shooting until the bolt carrier group has returned to a place that involve the bolt is in locked position. When performing automatic firing, the disconnector is disengaged either permanently by the selector (automatic mode) or temporarily by the counting device (3-rounds burst mode). Small oddity: the main sear is doubled (which explains the use of quotation marks above). Consisting of a single piece, it simultaneously takes in the hammer by the “foot” and on the intermediate crest. This provision, undoubtedly safe, is probably intended to provide the hammer with a better impact resistance in a cocked position.

To this is added a counting device for the burst of 3 shots, inherited from the CAL, which we will qualify as “linear rack”, as opposed to the “rotating rack” system. This device counts the hammer’s movements to release the pressure exerted on the disconnector after the start of the third shot. The counting cycle is reset each time the shooter releases the trigger, like the HK systems and unlike the systems present on M16A2 or Ruger AC-556.

Note here that this device, although very well done, was not retained for the Swedish AK-5. From a personal point of view, we agree with this decision: a limited burst is not useful from our point of view, because the results obtained are statistically always disappointing for a considerable increase in costs and manufacturing time.

In keeping with NATO interoperability needs, the magazine is globally that of the M16A1. Its realization differs, however, in certain respects, on the design of the follower, by the use of steel instead of aluminum for the body and by an easier method of disassembly. We read while doing our research that compatibility issues would exist. This is quite possible: the original magazine of the AR-15, like almost the entire weapon, is poorly designed. This prompted the various manufacturers using this drawing to slightly modify the magazines or the magazines wells in a quest for reliability. Other manufacturers have distanced themselves from this gunsmithing heresy by offering “proprietary” magazines allowing them to better guarantee the level of reliability of the weapon. Always remember here, that reliability for a soldier, is not the same than the one of a civilian shooter.

Disassembly

The field disassembly of the weapon is easy. Pull off the rear and front pins, in order to separate the two receivers. Begin the extraction of recoil spring assembly which comes along with the bolt carrier group towards the rear of the upper receiver. When the cocking handle reaches the end of its path, remove it by pulling it outwards. Then complete the extraction of the recoil spring assembly / bolt carrier group. Note that it is possible to proceed with the summary disassembly simply by tilting the upper receiver after only pulling off the rear pin. However, for routine maintenance, the removal of both pins will be encouraged, which provides greater ease in cleaning operations.

Remove the bolt from its carrier by pushing it slightly and rotating it and remove the recoil spring assembly … in the same way! No doubt, this weapon is intended for the harsh daily life of the soldier, which is a very high quality.

The handguard is composed of two half-shells that are held by a fitting at the back and by an elastic steel clip at the front. Its removal allows accessibility to the outer surface of the barrel and to the gas tube for its disassembly. To remove the gas tube, override one of the positions of the regulator (rather on the left), then press the tube backwards to disengage the front portion of the gas block.

At this point, the user is left with 9 sub-assemblies that he can clean: the upper part of the weapon, the two half-shells of the handguard, the gas tube, the lower part, the bolt, the bolt carrier, the recoil spring assembly and not to forget … the cocking handle. To all that one has to add the magazines. The firing pin remains harnessed to the piece of maneuver, which avoids losing it but also damaging it.

The accessibility for cleaning is quite good, a very positive point for a weapon with a military vocation. This accessibility is also much higher than that of the FN SCAR…

Some will blame the risk of losing the cocking handle, but here, unlike the SIG 540, 550, Beretta AR-70, 70/90 and even the CAL, the cocking handle does not perform any assembly function. Thus, with the help of a makeshift means, you can always use your weapon, for example by chocking it with the help of an ammunition. We have tested this for you: it works.

Disassembling the trigger group is easy. The pin of the automatic fire control is removed after disengagement of its spring. The selector is extracted after being positioned at 12 o’clock, then the counting device is removed, which blocks the trigger and hammer pins by its presence. The rest of the part removal does not need further comments as it is simple to achieve: remove the pins and the parts that go with it.

The additional disassembly of the extractor and the firing pin requires a little tooling. It is probably not intended at the level of the soldier. It calls for the removal of elastic rolled pins each time. It should therefore only be carried out, if necessary, since the disassembling of this type of pin normally requires systematic replacement. Allow us a little advice if you proceed to the disassembling of this type of pin without being able to replace them. At first, avoid completely taking the pin out of its housing if possible. Push it only as it is needed for the removal of the part. When reassembling, always push it in by means of a pin punch and never by direct hammer strike. Remember to keep all the parts aligned… of course!

It is noted that the Belgians kept the design of the extractor of the AK-47 and AKM, while the Soviets abandoned it in the transition to the AK-74. The Soviets had favored a design of extractor and bolt in greater adequacy with the use of second-generation intermediate caliber (5,56×45, 5,45×39 to name only the most well-known). The extractor spring of the FNC-80 is however “stiffer” than that of the AK-47 and AKM. The ejector is, like the AK, fixed in the upper receiver. The ejection force is therefore produced by the speed of recoil of the moving assembly (we speak of cycle speed): the higher this speed, the stronger the ejection. This type of ejection, more complex to integrate than a spring-loaded ejector into the architecture of the weapon, and much more reliable: it does not depend on the reliability of a spring and the good movement of a small part and avoids the problems of ejections related to over-cycle.

Shooting

True to what can be expected from a weapon in 5.56, the weapon produces light recoil. Two small nuances, however. First, the releasing weight is terribly high, even for a military weapon: more than 4.5 kg on our sample, which is equivalent to a double actionThe "double action" is a trigger mechanism where the action ... More on a handgun. Then the iron sight. Always preferring on a personal level, the notch for military use (better conservation of the field of view, less decrease in brightness across the line of sight), a second problem is added here. The folding stock version at our disposal for testing has at its base a large reflective surface that interferes with the brightness perceived by the eye when aiming. In certain light conditions, the shooting becomes very laborious and tiring for the eye. Certainly, the problem is not insoluble, it is enough to cover this surface with a less reflective material, such as textile. But it is better to be aware of the problem before the situation arises in an operational context. For our part, we discovered this on a long shooting session in January, which was particularly rainy and dark.

While conducting automatic fire, the slow rate of fire promotes good control of the weapon, on short and even long bursts. It is easy to produce two-shot bursts on each of the two burst modes. Remember that the use of the burst on this type of weapon is devolved to short-range engagements where the inability to produce a correct aiming is compensated by saturation.

The precision is consistent with the use of the weapon: with iron sight, the weapon authorizes the engagement of a human chest with 100% of the shots to the goal as far as 400m. Our tests carried out at 100, 200, 300 and 400 m with the SS-109 easily confirm this: our average H+W (Height + Width) at 400 m is 37 + 30 cm. And the test conditions were far from optimal in this month of January! Engagement with optical aiming undoubtedly makes it possible to extend this capability. Here it is necessary to be rational by not dwelling on too advanced numerical analyses: it is a weapon for war, not a weapon for competition. The results obtained on a firing range are not necessarily reproducible in operational conditions.

In conclusion

The FNC-80 is an authentic and valid weapon for war. It compiles already proven technologies to traditional elements of FN Herstal. This is in no way a reproach but on the contrary a great quality: in terms of weapons for war, the end justifies the means. Therefore, it does not succumb to various chimeras to keep in sight its combat vocation. “Another tremendous advantage is that the FNC with 200 rounds is not heavier than a 7,62 mm rifle with 50 rounds only.” This selling point of the FN makes us aware above all of its anachronism: more than 3 decades after the 7.92×33 Kruz, it seems that the West discovered the logistics benefits of intermediate munitions. The fault lies with NATO, not with the Belgians. They had seen the benefits of the intermediate caliber very early and even designed the first versions of the FAL for these calibers. They were also the ones who finally offered a more efficient alternative to the mediocre M193 with the SS-109. Despite its caliber and age, the FNC-80 could be likened to a Soviet AKM. Why not to the AK-74? Simply because the AK-74 offers a significant number of advances and pragmatic thinking compared to the excellent tool that the AKM already constitutes, in terms of productivity, shooting control and ballistics thanks to the 5,45×39. This is not the case with the FNC: it simply proposes a pragmatic and effective solution to a Western need, which is already a lot. The formidable AKM already offered great advances compared to the excellent AK-47 in terms of productivity and shooting skills, so it’s an honor to be compared to it!

Arnaud LAMOTHE

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!

Here is the nomenclature of the FNC for the American market:

Model 2000, rifle (“standard” barrel) with 1:178 mm (1:7″) twist rate.

Model 7000, rifle (short barrel) with 1:178 mm (1:7″) twist rate.

Model 0000, rifle (“standard” barrel) with 1:305 mm (1:12″) twist rate.

Model 6000, rifle (short barrel) with 1:305 mm (1:12″) twist rate.

Model 7030, semi-automatic version of the rifle (“standard” barrel) with 1:178 mm (1:7″) twist rate.

Model 6040, semi-automatic version of the rifle (“standard” barrel) with 1:305 mm (1:12″) twist rate.

Acknowledgements:

WOLF from TR-Equipement, without whom nothing would have been possible.

Pierre BREUVART, for his advice and teachings in all areas!

Jimmy LAFARGE, to undergo my advice and my teachings.